Quality since 1946

5

9049 Tyler Blvd. • Mentor, Ohio 44060

Phone (440) 974-8888 • Fax (440) 974-0165

Toll-Free Fax 800-841-8003 • buyersproducts.com

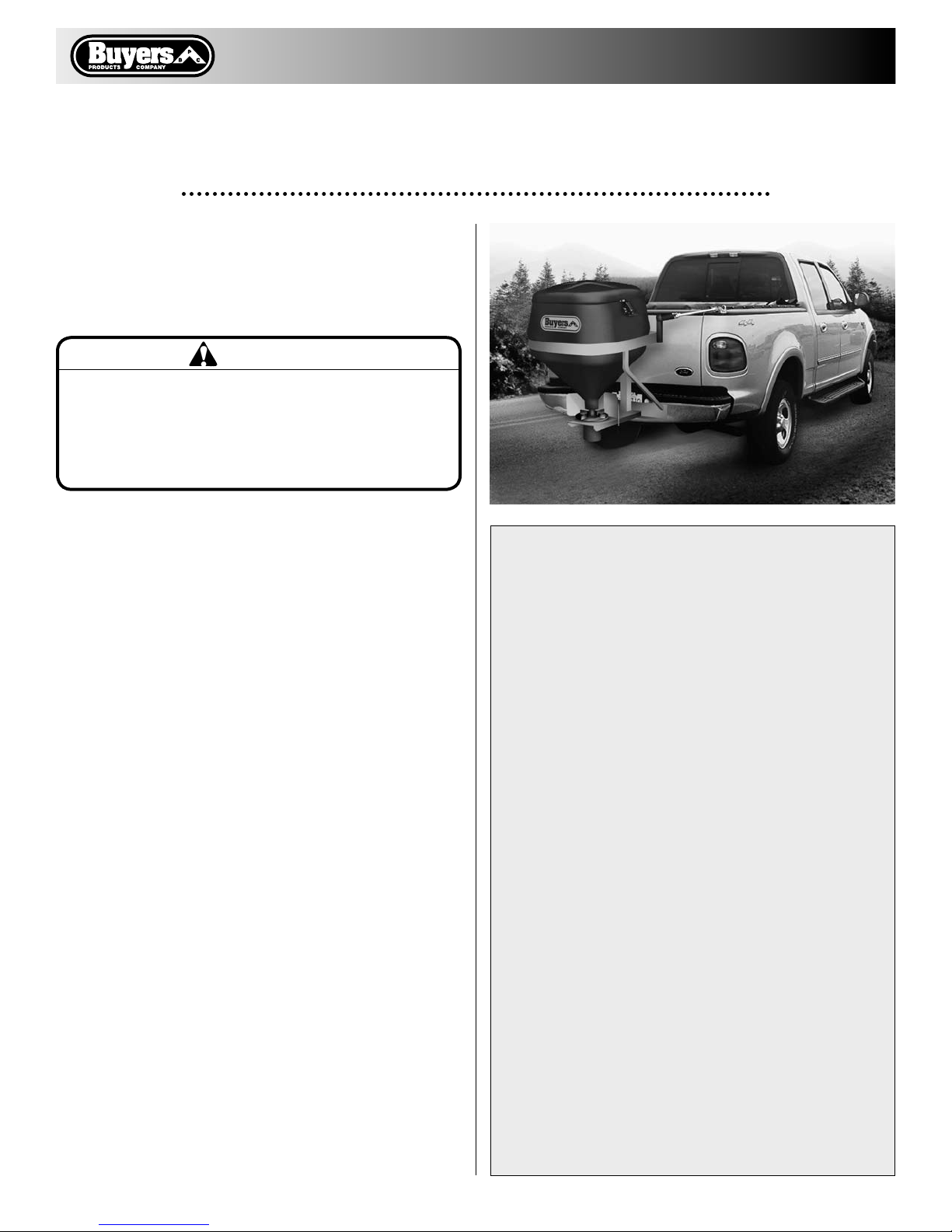

Installation Instructions

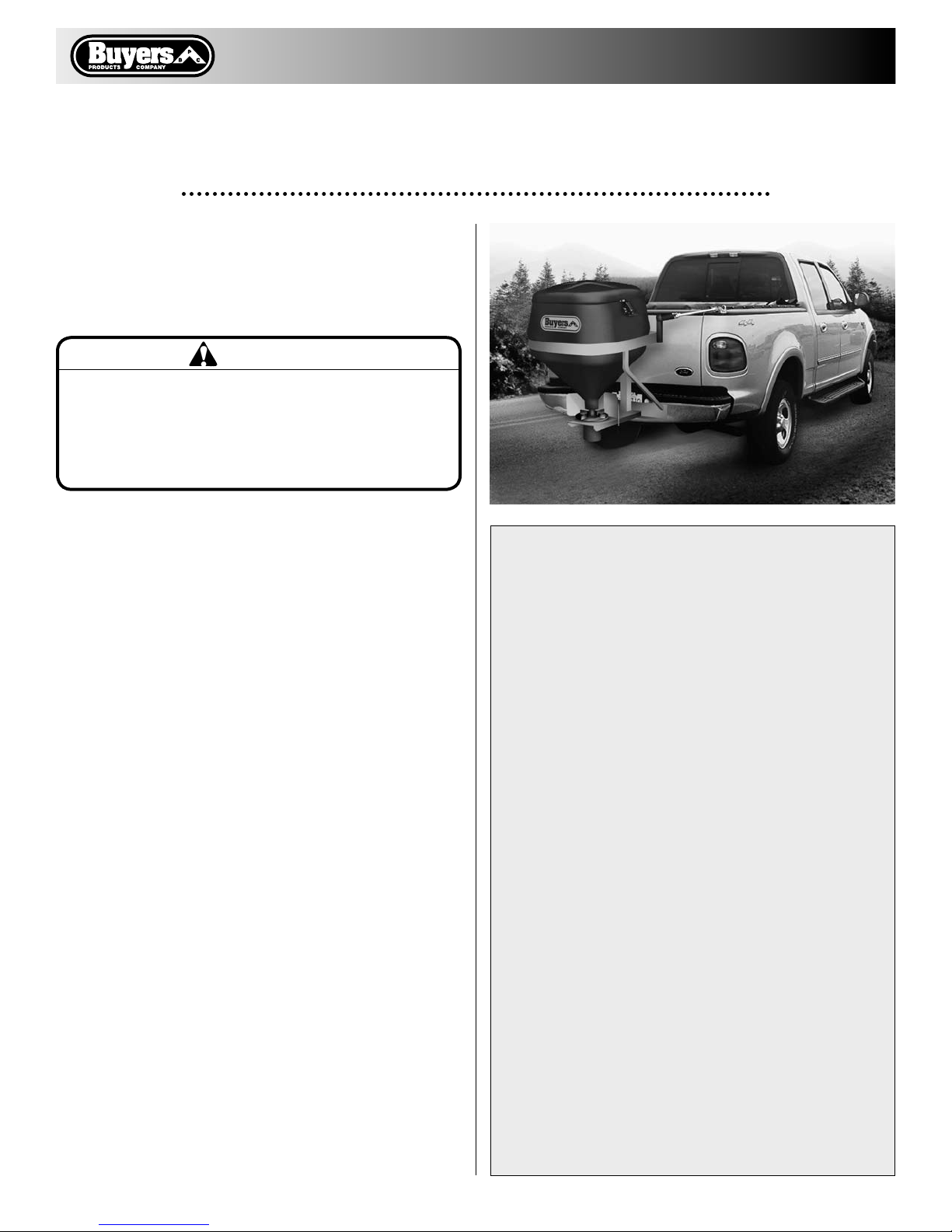

TGS01B Salt Spreader

—continued inside

WARNING

Observe the following Safety Precautions before, dur-

ing and after operating this spreader. By following

these precautions and common sense, possible injury to

persons and potential damage to this machine may be

avoided.

SPREADER WARRANTY INFORMATION

This warranty replaces all previous warranties and

no employee of this company is authorized to extend

additional warranties, or agreements, or implications

not explicitly covered herein.

Buyers Products Company warrants all parts of the

product to be free from defects in material and work-

manship for a period of one (1) year. Parts must be

properly installed and used under normal conditions.

Normal wear is excluded.

Any part, which has been altered, including modifica-

tions, misuse, accident, or lack of maintenance will

not be considered under this warranty.

The sole responsibility of Buyers Products Company

under this warranty is limited to repairing or replac-

ing any part(s), which are returned, prepaid, 30

days after such defect is discovered, and returned

part(s) are found to be defective by Buyers Products

Company.

Authorization from Buyers Products Company must

be obtained before returning any part. The following

information must accompany defective parts returned

to Buyers Products Company: RMA #, spreader model,

serial number, date installed, and distributor from

whom purchased.

Buyers Products Company shall not be liable for

damage arising out of failure of any unit to operate

properly, or failure, or delay in work, or for any con-

sequential damages. No charges for transportation

or labor performed on any part will be allowed under

this warranty.

Safety Precautions

1. Read this entire Owners Manual before operat-

ing this spreader.

2. Read all safety decals on the spreader before

operating.

3. Verify that all personnel are clear of the spread-

er spray area before starting or operating this

spreader.

4. Do not adjust, clean, lubricate or unclog material

jambs without first turning off the spreader.

5. Make sure the spreader is securely fastened to

the vehicle in accordance with this manual.

6. Do not operate a spreader that is in need of

maintenance or repairs.

7. Always disconnect the battery before removing

or replacing electrical components.

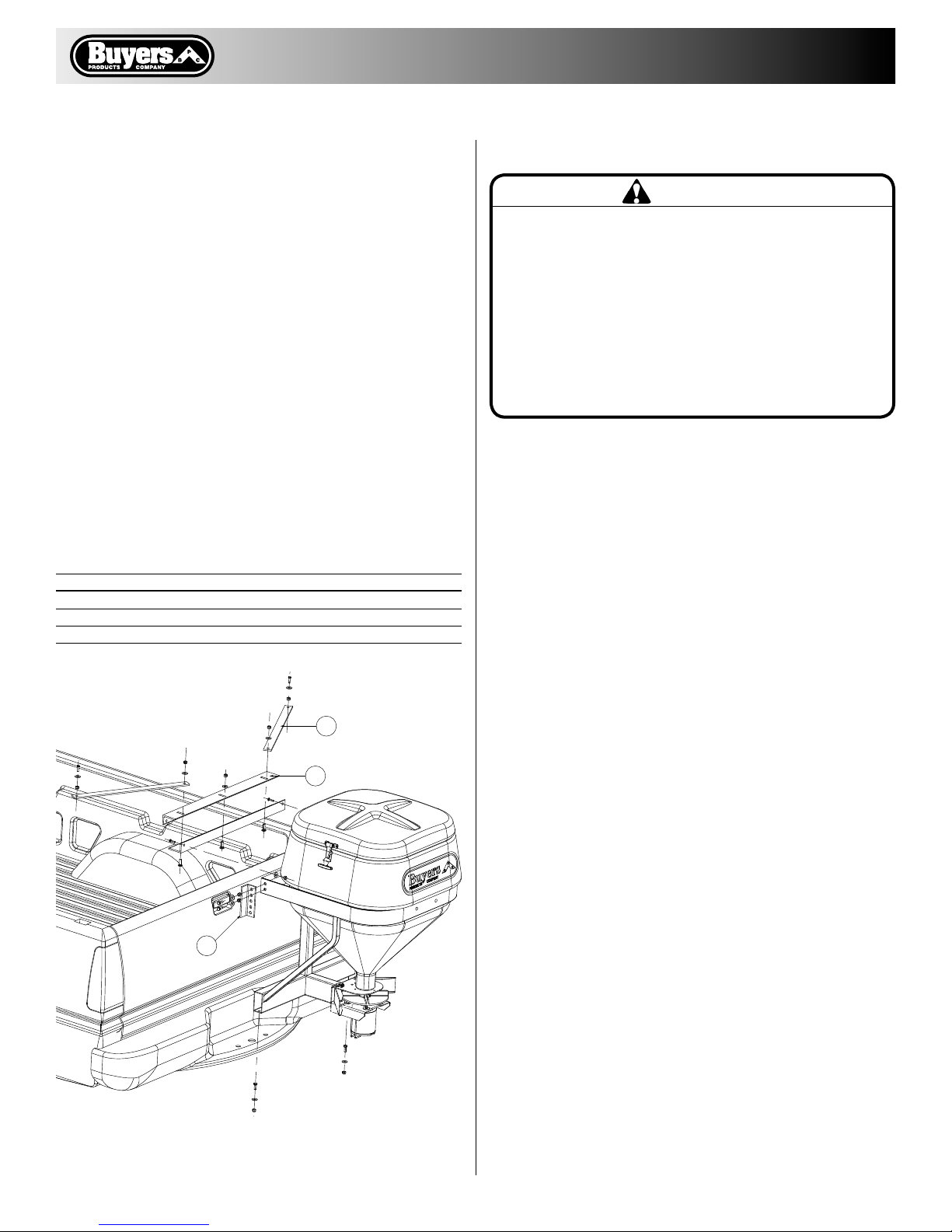

Spreader Assembly

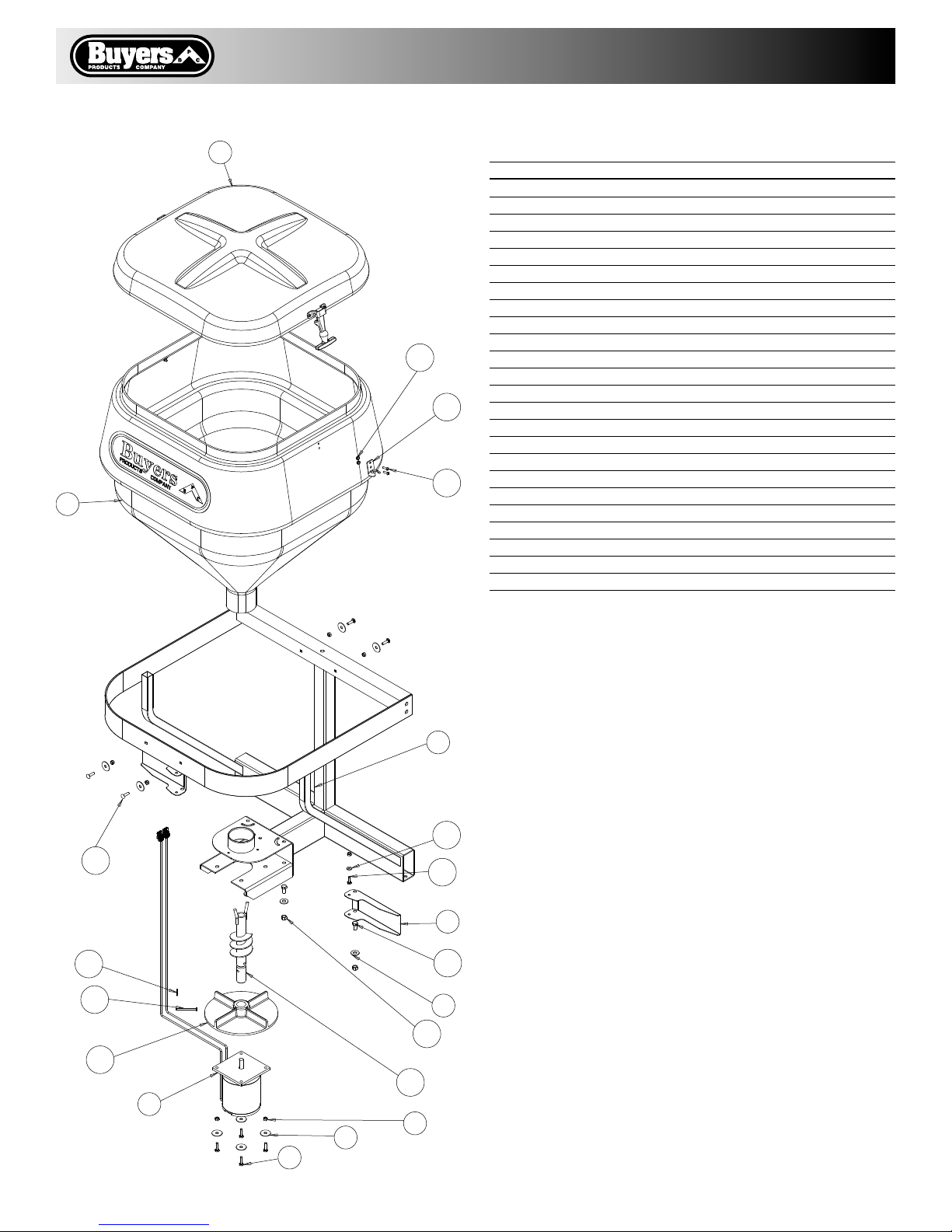

Check contents of box against parts list to make

sure all components are included. When ordering

replacement or spare parts refer to parts list (fig. 3)

for part numbers.

Installation (fig. 1)

1. Locate and mark center of tailgate.

2. Assembly Angles (24) and Braces (23) as shown

in Fig.1 Use 3/8" carriage bolts, flat washers and

nuts. Do not tighten fasteners at this moment.

3. Center assembly on top of tailgate. Lower angle

must be flush with top and inside surfaces of

tailgate.