BW-VG425

High Precision CAN bus Dynamic Inclination Sensor

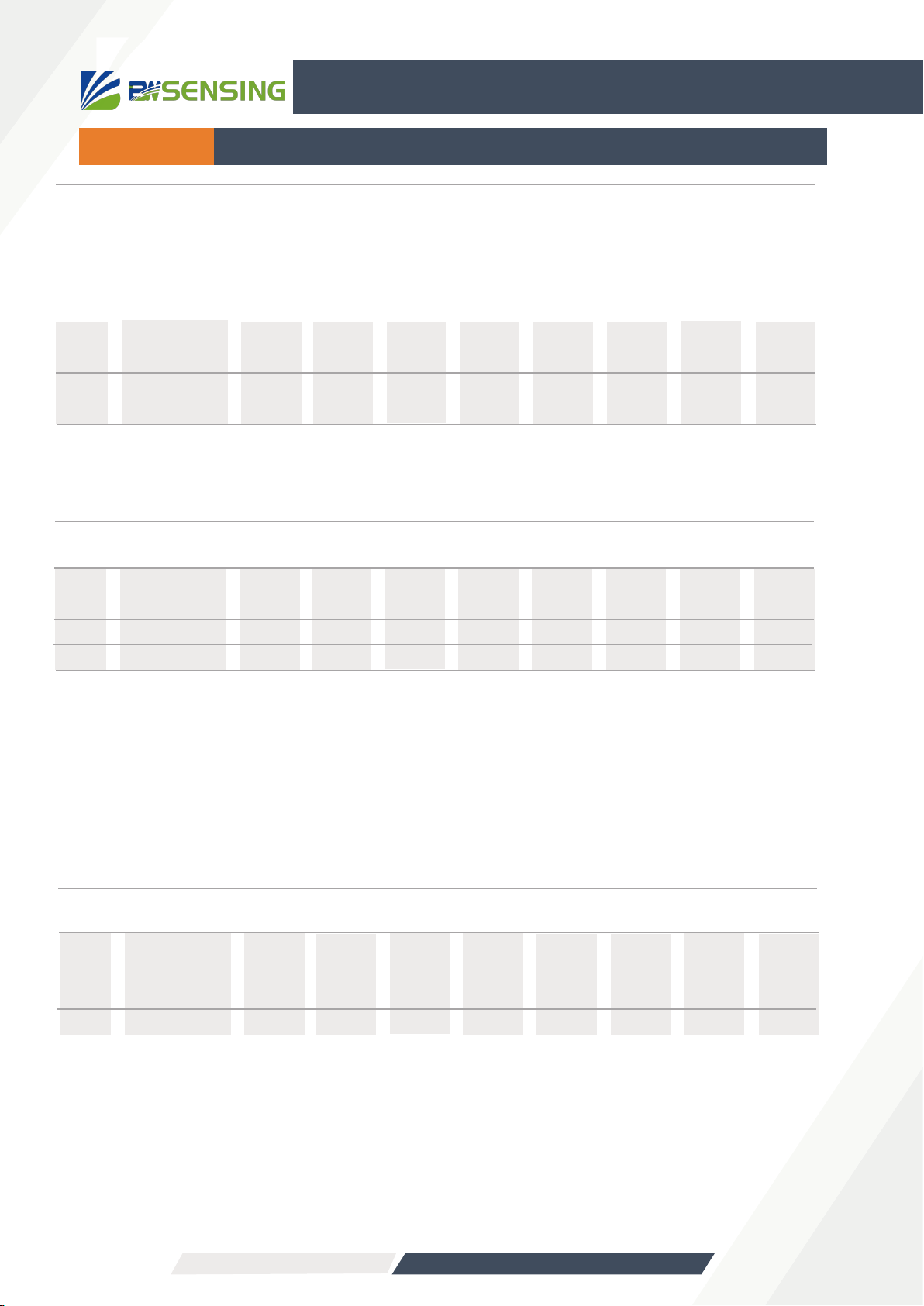

Protocol

The CAN includes 8 bytes, and add 0 to it if the data byte is not enough . Sending the first byte 0x40 indicates

a write command, returning the first byte 0x40 indicates that the write was successful. The ID is the CAN

communication node number.

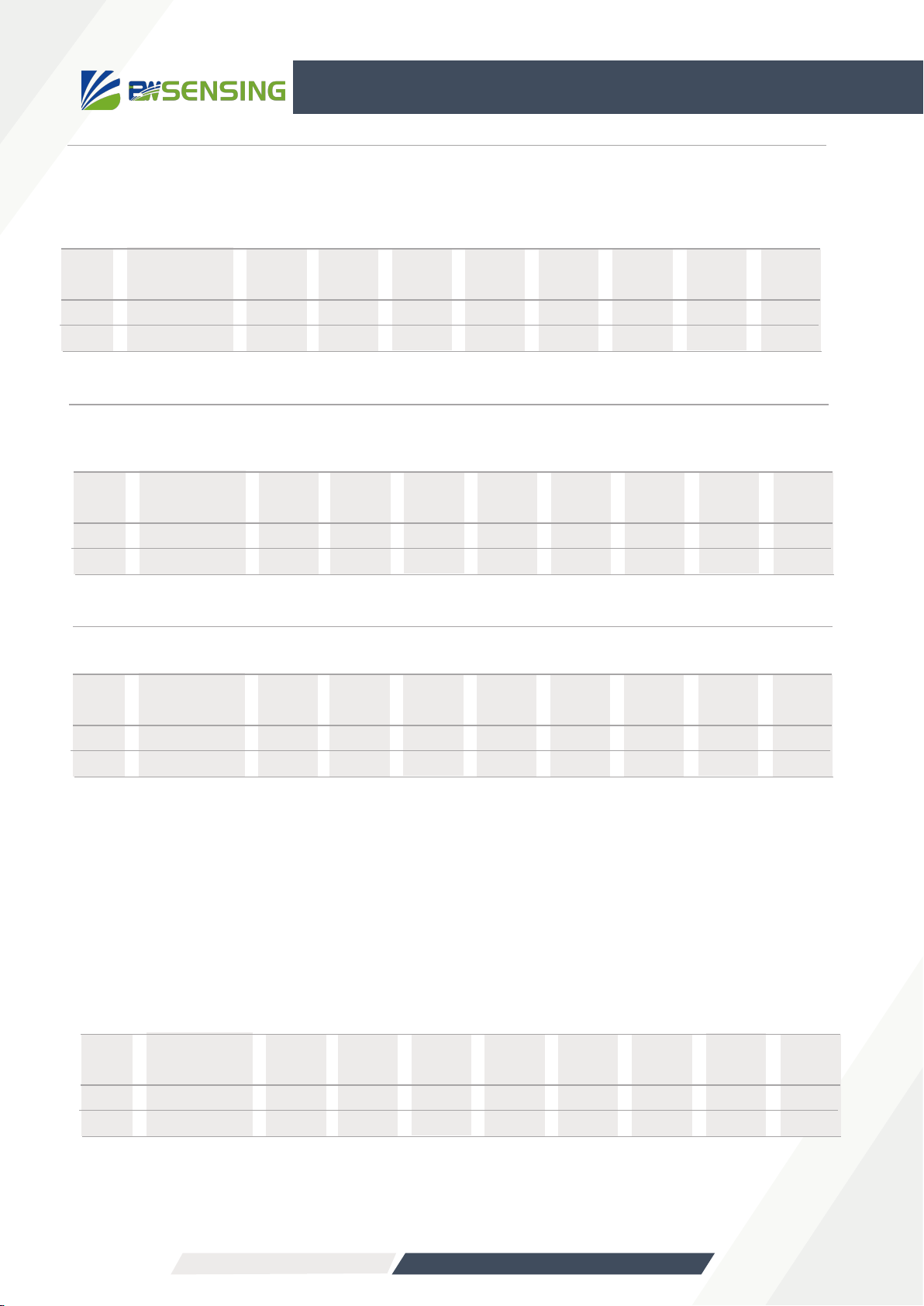

2)Set the CAN baud rate:

Note: The fifth byte (Baud) is 0x01, 0x02, 0x03, 0x04, 0x05, 0x06.

0x01 represents the setting baud rate of 500K bps

0x02 represents the setting baud rate of 250K bps

0x03 represents the setting baud rate of 125K bps

0x04 represents the setting baud rate of 100K bps

0x05 represents the setting baud rate of 50K bps

0x06 represents the setting baud rate of 25K bps

The default baud rate is 125K bps. After modifying the baud rate, the sensor needs to be powered on

again, and the baud rate modification can be successful. The lower the baud rate, the shorter the

communication distance. The communication distance can reach more than 1000m at 25K bps.

3)Set relative \ absolute zero

1)Modify node number:

(ID=0x01~0x7F),The default node number (ID) is 0x05

Send

Respond

CAN-ID

0x600+0x05

0x580+0xID

First

byte

0x40

0x40

Second

byte

0x10

0x10

Third

byte

0x10

0x10

Fourth

byte

0x00

0x00

Fifth

byte

ID

ID

Sixth

byte

0x00

0x00

Seventh

byte

0x00

0x00

Eighth

byte

0x00

0x00

Note: If the controller sends CAN-ID=0x600+0x05 (default), send data: 40 10 10 00 10 00 00 00,The sensor returns CAN-

ID=0x580+0x10 and returns data: 40 10 10 00 10 00 00 00,

The CAN-ID is 0x590 (0x580+0x10), indicating that the ID modification is successful. At this time, when sending other

naming, the CAN-ID needs to be changed to 0x610 to be successfully transmitted.

Note: The 5th byte Type is 0x00, 0x01. 0x00 means set to absolute zero, 0x01 means set to relative zero,

After setting the zero point, you need to enter the save command to set the success (the default is

absolute zero).

Send

Respond

CAN-ID

0x600+0x05

First

byte

0x40

Second

byte

0x20

Third

byte

0x10

Fourth

byte

0x00

Fifth

byte

Baud

Sixth

byte

0x00

Seventh

byte

0x00

Eighth

byte

0x00

Send

Respond

CAN-ID

0x600+0x05

0x580+0x05

First

byte

0x40

0x40

Second

byte

0x05

0x05

Third

byte

0x10

0x10

Fourth

byte

0x00

0x00

Fifth

byte

Type

0x00

Sixth

byte

0x00

0x00

Seventh

byte

0x00

0x00

Eighth

byte

0x00

0x00

Bewis Sensing Technology LLC www.bwsensing.com Tel:+86 189 0617 7922