6/48 2019/01 - Indice de révision : A - Code : 97160421 WOODEN POOLS BWT myPOOL

HOTLINE

2. FOREWORD

Congratulations on acquiring your pool. We have taken great care with the design and manufacture of your

pool to provide you with a top quality product.

The wood used to make the various elements (interlocking walls, coping, ladder, etc.) was carefully

selected. Outdoors, these wooden elements are subject to constant weathering: contact with the ground,

temperature variations, exposure to sunlight, rain and frost, insect attack, etc. The wood’s ability to

withstand this aggression depends on the origin of the wood and the method used to treat it.

For this reason, we choose pine from extensive, sustainably managed forests in northern Europe. Why do

we insist on this? Because the more rigorous climates above the 57th parallel favour very slow tree growth,

making the wood stronger and more resilient.

The wood is autoclaved, this involves subjecting the wood alternately to pressure and vacuum in order to

drivethetreatmentchemicalsintotheheartofthewoodasopposedtoothermoresupercialtreatment

techniques such as soaking.

Class IV treated wood in contact with the ground is immune to insect attack and rotting caused by humidity.

Autoclave treatment is guaranteed 10 years, in accordance with standards currently in effect.

The pool coping is made of either composite slats or grooved pine planks, depending on the model selected.

Wood is a living material, variations in temperature and humidity can cause it to expand or contract so take

care to follow the storage and assembly instructions concerning the wooden structure. Similarly, prolonged

exposure to UV light can cause wood to grey. These are natural phenomena that in no way effect the

service life of the products.

Do not apply any product to the wood (for example: lazure, micro-porous products, etc.).

3. STORAGE & ASSEMBLY TIMES

Weshallnowexplainhowtoassembleyourpool,butrstsomeinstructionsbeforeyoubegin.

Please read these instructions carefully, this will allow you to prepare each stage to achieve optimum

efciency.Pleasekeeptheseinstructionsforfuturereference.

You should take the time to go through the components using the nomenclature page enclosed with the

accessories kit and make sure that no items are missing.

Please retain the following documents;

• the production sheets for the various kits

• proofs of purchase

3.1 Storage

If you do not intend to assemble your pool immediately, you should store it without opening it, in a well

ventilated room, or failing this, in an area protected from humidity and sunlight. Once the pallets are

undone, the kit must be assembled within 24 hours. Once work has begun, try to avoid leaving the structure

exposedtosignicantclimaticvariationsthatcouldcausethewoodto“work”tooquickly.Thiscouldlead

to deformations that could render the item unusable. By preference, the wooden structure should be

assembledinonegoonadaythatisnottoohot.ThelinerorPVCwaterproongmembraneshouldbe

storedataminimumof20°Cforatleast24hoursbeforeitistted.Thisistorenderthelinermoresupple

andthusfacilitatetting.Thelinershouldonlybettediftheambienttemperatureishigherthan20°C.

3.2 Above-ground kit

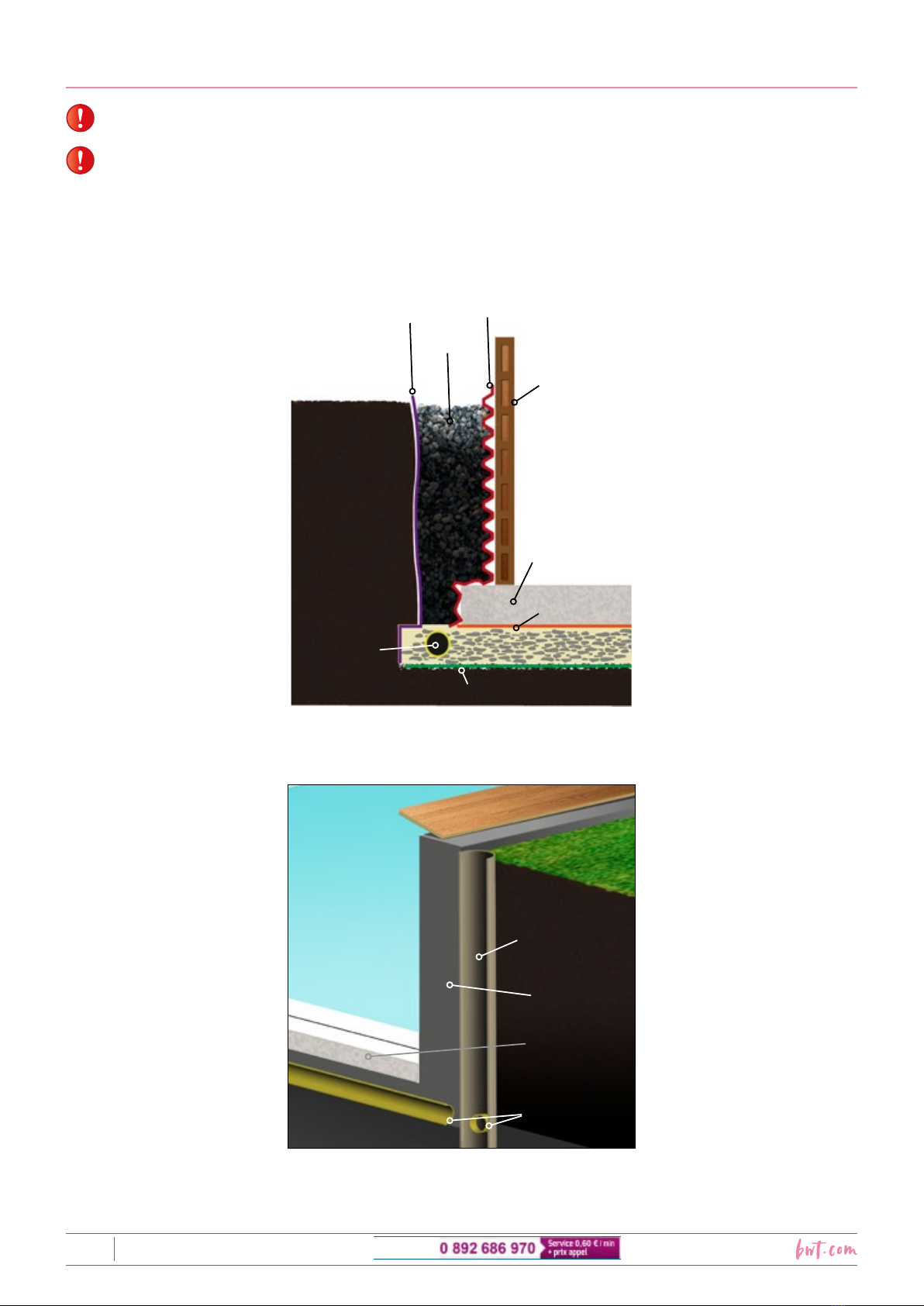

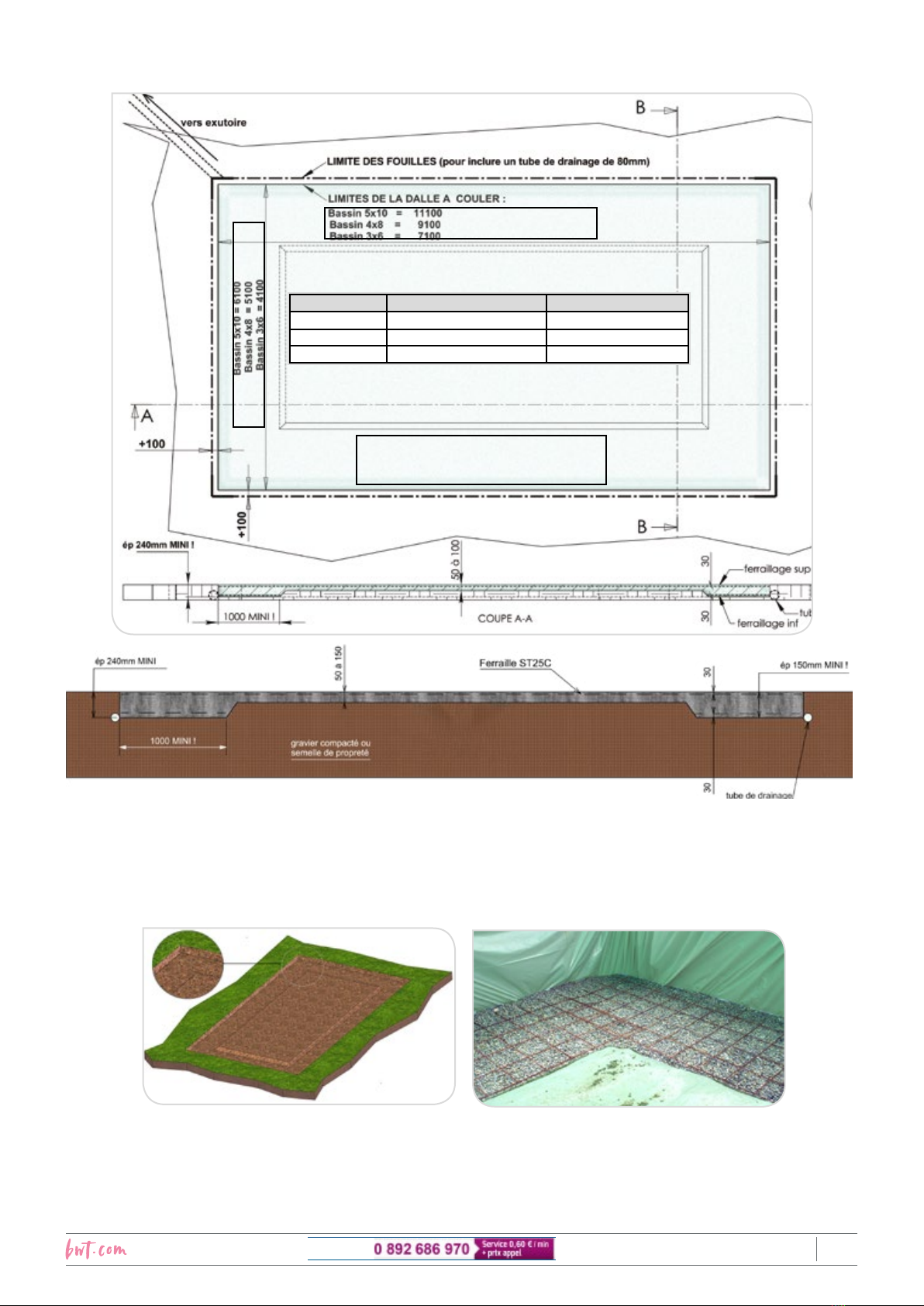

The kit delivered is intended for installation above-ground. If the pool is to be installed partially or entirely

in-ground, additional measures will need to be taken :

• Ifthegroundisnotlevel,digintotheslope,neverbackllunderthepool.

• Takecaretoensuresufcientdrainageadaptedtotheterrainaroundtheperipheryoftheconcrete