4/44 2020/09- Version: L Code : 97112223 BWT myPOOL TROPIC WIOODEN POOLS

HOTLINE

1. WOOD, A NATURAL MATERIAL

Beinganaturalmaterial,woodwillhavesomeimperfections.Thesearenormalandhavenoimpacton

theservicelifeoftheproduct.Acertainnumberaresupercialanddonotfallwithinthescopeofthe

guarantees.

1.1 Resin beads

Whenresinouswoodspeciesareautoclaved,thealternatingpressure

andvacuumcancausestickyresiduetorisetothesurface.Toremove

it,scrapeitcarefullywithanappropriatetool,beingcarefulnottotouch

thewood.Turpentinespiritscouldalsobeeffective,butcouldstainthe

woodiftoomuchisapplied.

1.2 Salt stains

Les bois traités en autoclave montrent fréquemment de petites taches

vertes en surface. Si vous le souhaitez, vous pouvez les poncer

légèrement. Cette couleur disparaîtra dans le temps.

1.3 Greying

Wood exposed to the elements is susceptible to greying. Some people

appreciate the silvery sheen of this natural patina.e.

1.4 Splitting and cracking

Woodexpandsandcontractswhenexposedtovariationsinhumidity

andtemperature.Asitdries,woodcontractsunevenlyresultinginthe

appearance of cracks. While these can seem to be cause for concern,

they have no impact on the mechanical properties of the product and

thereforedonotfallwithinthescopeoftheguarantee.

1.5 Knots

Knots mark the places where branches were attached. The quantity

andsizedependsonthespeciesofwoodandthesortingprocess.For

outdoorinstallations,smalladherentknotsareacceptable.Themore

woodissortedtolimitthesizeandnumberofknots,themoreexpensive

thewood.

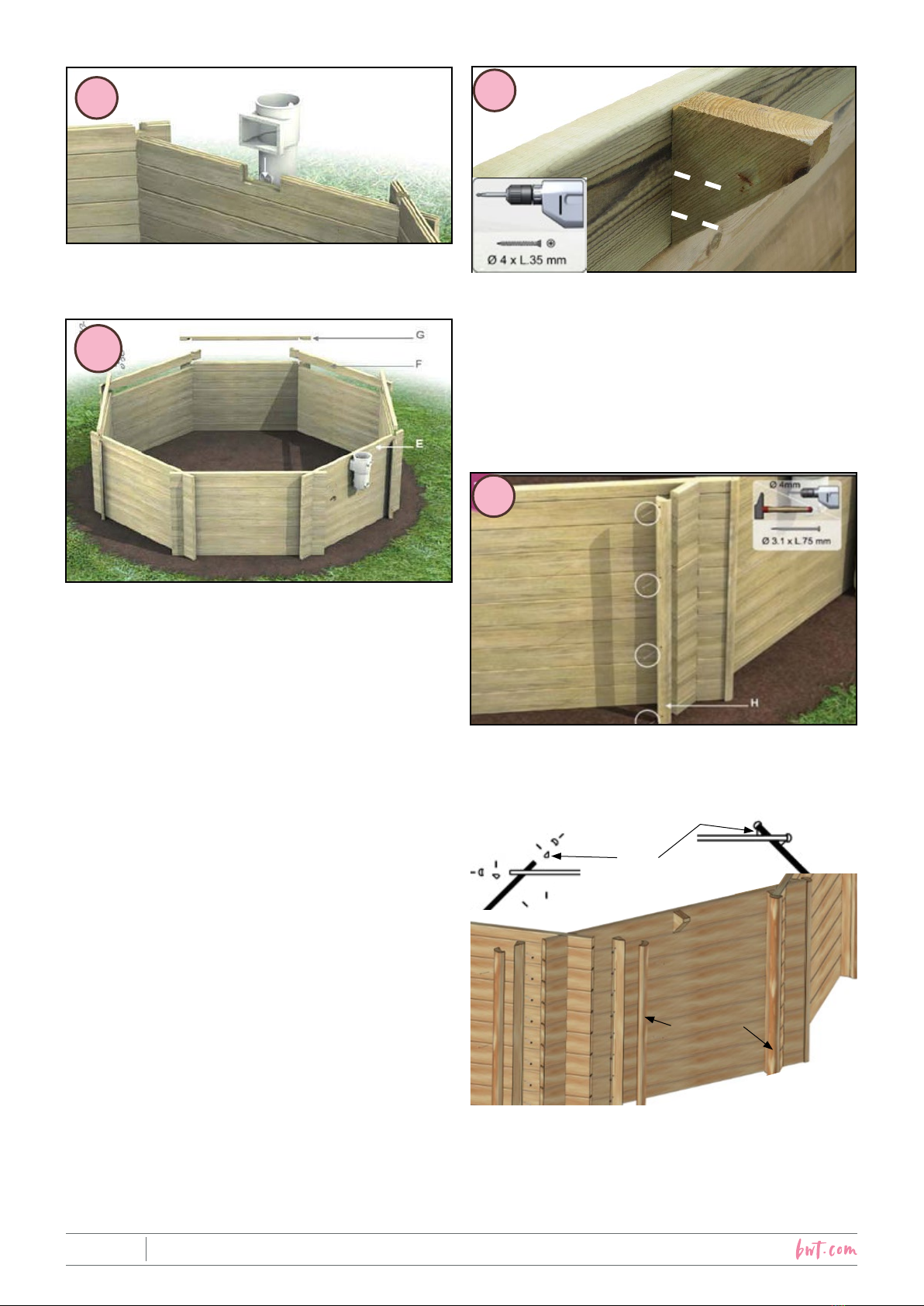

1.6 Joined wood

Toensurethehighestqualityintheselectionofourwood,itissorted

meticulously before planing. Sections that feature defects (knots,

cracks,etc.)onbothsidesareremovedandthewoodisthenjoined

together(seeimage).Itisnotunusualtondjoinedslatsinthewooden

poolstructure as thisinnoway penalises themechanicalproperties

ofthewood.Similarly,imperfectionsontheinnersurfaceofthepool

structure (knots, cracks, etc.) are also acceptable.

1.7 Surface mould

Mould,causedbymicroscopicfungi,cangrowonwood,particularlyon

resinousspecies,onwhichthegrowthcanappearas“blueing”.Itisa

surface phenomenon, exacerbated by heat, humidity and inadequate

aeration and is characterised by stains ranging from light to dark blue.

Theycanberemovedbywipingthesurface.RememberthatclassIVtreatedwoodisprotectedagainst

attackbyfungithatcoulddestroythephysicalandmechanicalpropertiesofthewood.Formoredetail,see

the MyPool guarantees covering the species and the treatment.