- 3 -

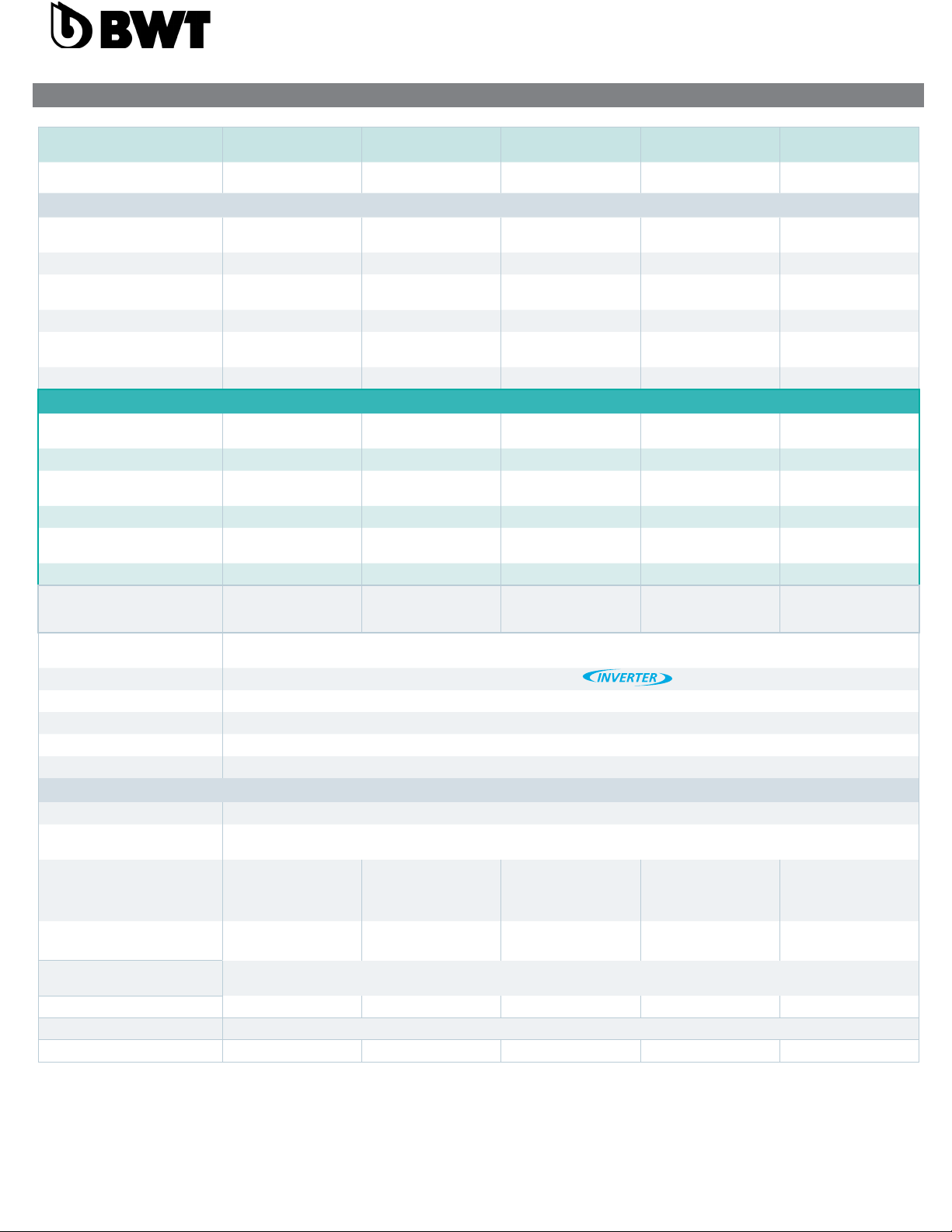

TECHNICAL SPECIFICATIONS

Models BWT PEARL HPT09 BWT PEARL HPT12 BWT PEARL HPT15 BWT PEARL HPT18 BWT PEARL HPT20

Recommended pool size

(Mai to septembre with a cover) 35-45 m³ 45-55 m³ 55-70 m³ 70-85 m³ 85-105 m³

Air 26°C / Water 26°C / 80%HR

Capacity in MAX Mode 9,5 kW 12,8 kW 15,3 kW 18,2 kW 20,1 kW

COP MAX Mode 6,3 6,2 6,3 6,2 6,1

Capacity in ECO Mode 9,5 ~ 3,2 kW 12,8 ~ 3,5 kW 15,3 ~ 3,9 kW 18,2 ~ 4,2 kW 20,1 ~ 5,5 kW

COP ECO Mode 10,8 ~ 6,3 10,8 ~ 6,2 10,8 ~ 6,3 11,2 ~ 6,2 10,8 ~ 6,1

Capacity in SILENT 3,2 kW 3,5 kW 3,9 kW 4,2 kW 5,5 kW

COP SILENT 10,8 10,8 10,8 11,2 10,8

Air 15°C / Water 26°C / 70%HR**

Capacity in MAX Mode 6,9 kW 9,1 kW 11,0 kW 12,7 kW 14,5 kW

COP MAX Mode 4,7 4,6 4,7 4,6 4,5

Capacity in ECO Mode 6,9 ~ 3,5 kW 9,1 ~ 3,9 kW 11,0 ~ 5,0 kW 12,7 ~ 7,1 kW 14,5 ~ 7,0 Kw

COP ECO Mode 6,6~4,7 7,8~4,6 7,7~4,7 7,9~4,6 7,9~4,5

Capacity in SILENT 3,5 kW 3,9 kW 5,0 kW 7,1 kW 7,0 kW

COP SILENT 6,4 6,6 6,5 6,6 6,6

Noise level mini-maxi (at 10m)

according to EN ISO 3744:2010 19 ~ 28 dB(a) 20 ~ 29 dB(a) 21 ~ 30 dB(a) 22 ~ 31 dB(a) 23 ~ 32 dB(a)

Operating temperature -10°C -> 38°C

Compresseor type 2D Technology Full DC

Expansion valve Electronic

Heat Exchanger Optimal Twist

Casing ABS treated against UV

Refrigerant R32

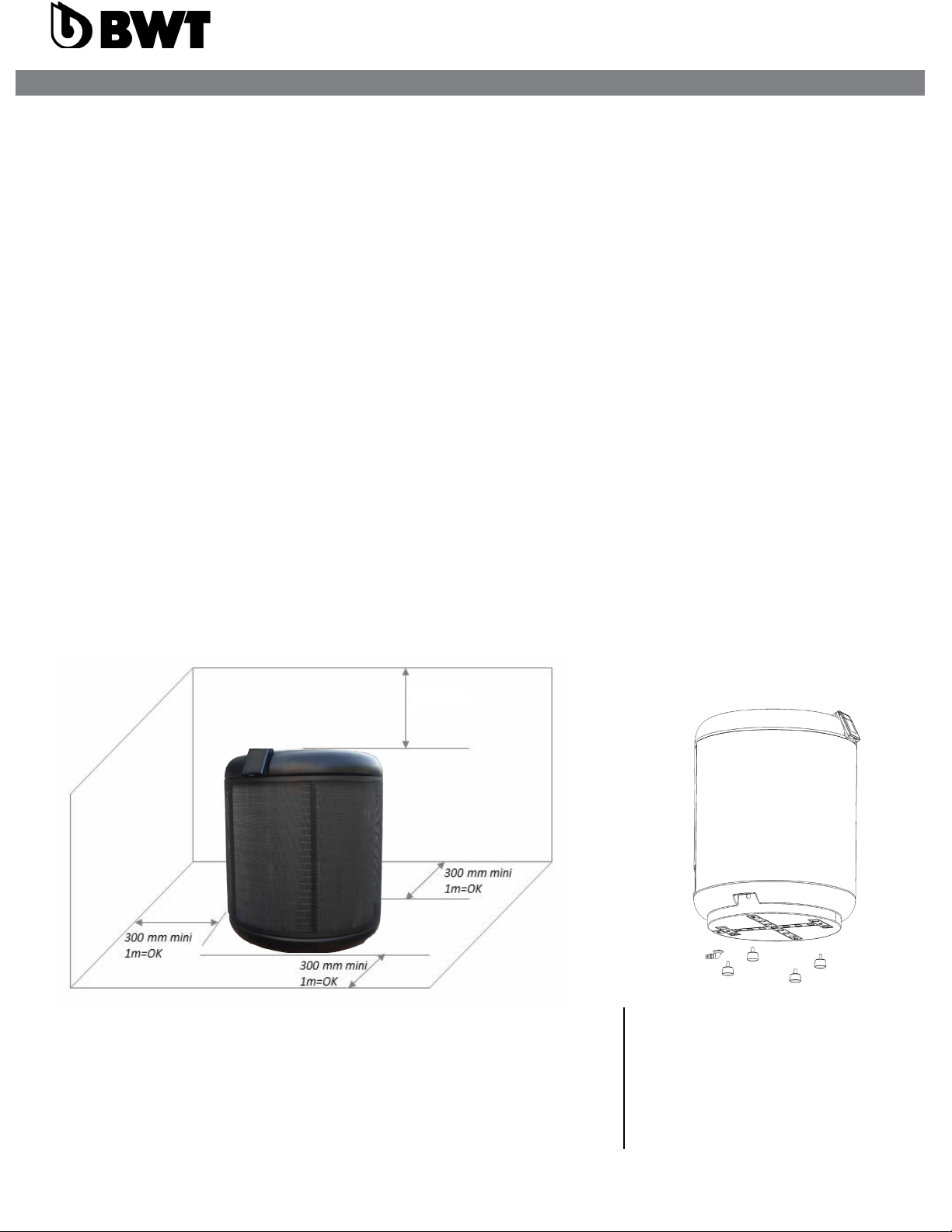

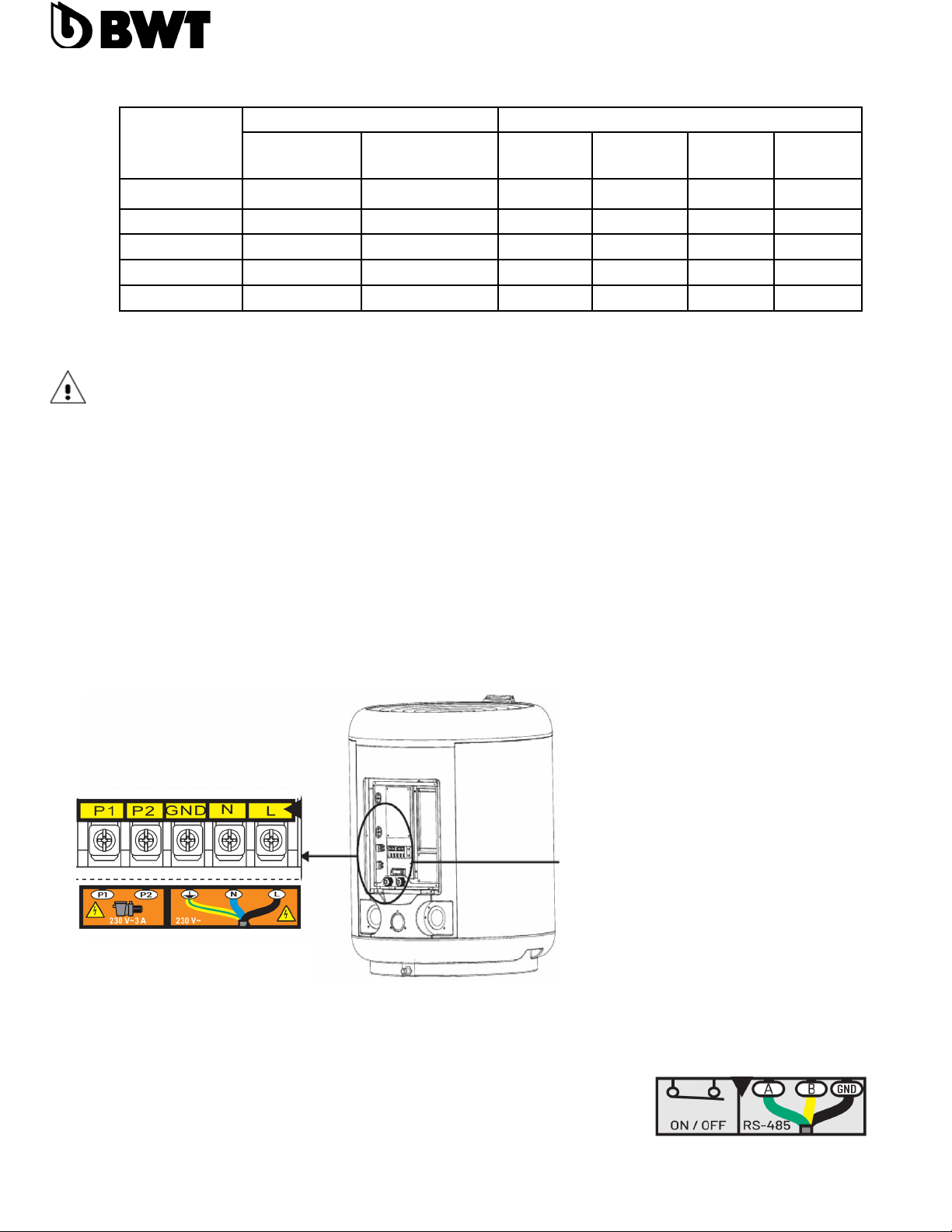

Installation

Water connection 1,5" / 50 mm

Power 230V / 1~+N / 50 Hz

Nominal current (Maximum

Current) 6,0 A (9 A) 7,9 A (13,0 A) 9,8 A (14,0 A) 11,5 A (16,0 A) 14,2A(17,0A)

Max power input (Air 26°C) 1,9 kW 2,6 kW 2,9 kW 3,8 kW 4,2 kW

Dimensions (L x l x h) Diameter 680 mm * height 775 mm

Water flow 3 m³/h 4 m³/h 5 m³/h 5 m³/h 6 m³/h

Water pressure drop 64 kPa

Weight net (gross) 45 kg (65 kg) 47 kg (69 kg) 49 kg (70kg) 57 kg (76 kg) 59 kg (76 kg)