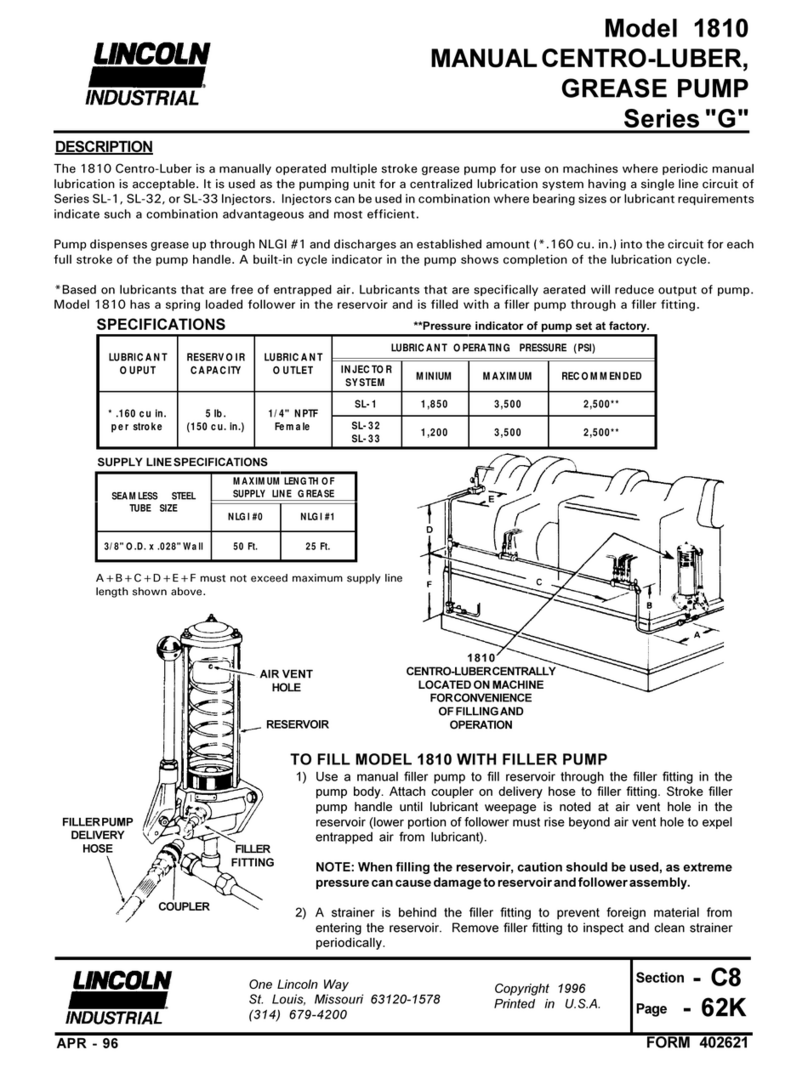

INSTRUCTIONS FOR PUMP USING 85209 CONTROL PANEL

TO PRIME SYSTEM

SUPPLY LINES:

After pump reservoir has been filled with recommended lubricant,

loosen all plugs in dead ends of injector manifolds and supply lines.

Turn vent plug in pump counter-clockwise one complete turn. Depress

manual lube pushbutton on door to start pump. Operate pump until

lubricant bleeds around vent plug to expel air pockets trapped between

the pump and the supply line connection. Tighten vent plug. continue

operating pump unitl lubricant flows around any plug. Tighten plug.

Repeat this procedure until all plug openings are tight and supply lines

are primed. Turn off power to reset controller.

IMPORTANT:

Refer to Owner/Operator Manual C8 259 to program controller on

85209.

FEEDER LINES:

Fill each feed line with lubricant before connecting lines to outlets of

injectors and bearings. This will prevent having to cycle each injector

to fill the feed line between injector and bearing.

INJECTORS:

Checkthe injectors for proper operationby observing the movement

of the indicator stems.

OPERATION:

When model 85530 times out it will initiate a lube cycle. The air

solenoid is energized to deliver air to the pump and air to the vent

valve. Pump begins dispensing lubricant through injectors to the

bearings.

When all bearings have received lubricant, pressure rises in system

to actuate pressure switch. When pressure switch actuates, the

control is reset to de-energize solenoid valve cutting off air to pump

and vent valve. Pump stops, pressure vents and pressure switch

de-actuates. Control begins timing toward next lube event.

INSTRUCTIONS FOR PUMP USING 83820 TIME CONTROL

TO PRIME SYSTEM

SUPPLY LINES:

After pump reservoir has been filled with recommended lubricant,

loosen all plugs in dead ends of injectors manifolds and supply lines.

Turn vent plug in pump counter-clockwise one complete turn. Set the

delay relay to its maximum position (Refer to Service Manual Section

C8, Page 133 Sefies). Depress push button on top of time control

to start pump. Operate pump until lubricant bleeds around vent

plug to expel air pockets trapped between the pump and the supply

line connection. Tighten vent plug. Continue operating pump until

lubricant flows around any plug. Tighten plug. Repeat this procedure

until all plug openings are tight and supply lines are primed. Open

line switch to shut off pump.

IMPORTANT:

Reset the delay relay to desired interval (Refer to System Planning

Manual).

FEEDER LINES:

Fill each line with lubricant before connecting lines to outlets of

injectors and bearings. This will prevent having to cycle each injector

to fill the feed line between injector and bearing.

INJECTORS:

Check injectors for proper operation by observing the movement of

the indicator stems.

OPERATION

The timer (runs constantly when current is on), drives a cam which

has lobes set for the desired lubrication cycle frequency (Refer to

Service Manual Section C8, Page 133 Series). Lobes engage the

micro-switch lever arm to activate the switch, closing the circuit to

open the 3-way solenoid air valve permitting air to operate the pump.

The pump discharges lubricant through the supply line to the injectors.

After the injectors operate (discharge lubricant to the bearings), pump

continues to build up lubricant pressure in the supply line until sufficient

to operate the pressure control which moves a switch plate, breaking

the circuit to the 3-way, solenoid air valve, shutting off the air to the

pump. Injectors automatically, re-charge with lubricant and system

is ready for the next lubrication cycle.

The pressure controlis factory set for 2,500 psi,adequate for any normal

installation. If higher pressure is necessary (2,900 psi maximum), the

pressure control can be reset;

1) Loosen locknut.

2) Turn the housing clockwise into the pressure control body until

proper pressure is obtained.

3) Tighten locknut.

To lower pressure (1,500 psi minimum);

1) Loose locknut.

2) Turn the housing counter-clockwise into the pressure control

body until proper pressure is obtained.

3) Tighten locknut.

VENT VALVE:

The 83948 Vent Valve is operated by compressed air from the same

source which operates the pump. When pump is in operation, air

pressurekeeps theventvalve closed andlubricantisdirectedthroughthe

outlet and to the injectors. When air to the pump is shut off, vent valve

opens and supply line pressure vents back into the reservoir.

SAFETY UNLOADER:

90942 Safety unloader is provided at the pump outlet to prevent

the build-up of dangerously high lubricant pressure in the system. It

is factory set to open at approximately 3,750 psi to 4,250 psi.

NOTE: Safety unloader requires no adjustment and should not be

tamperedwith.

WHAT TO DO IF:

Pump loses prime: Check lubricant supply.

10127 Vent Plug is provided at the pump outlet for expelling air which

may be pocketed in the lubricant. If pump operated continuously

without discharging lubricant, it is an indication that the pump has lost

its prime. Loosen the vent plug one turn until trapped air is pumped out.

If pumpcontinues to operate withoutdischarginglubricant,10061 Pump

Check and 66002 Steel Ball may be fouled. Remove and clean checks

and check seats. The 83948 VentValve may also be fouled. Foreign

material may prevent 14722 Needle from seating proper]), or 14723

Valve Seat may be worn or damaged. Clean or replace parts.

Failure of injectors to cycle can also be caused by a leak in the supply

line. Examine lines and connections.

Pump fails to operate: Check air supply.

RETAIN THIS INFORMATION FOR FUTURE REFERENCE

When ordering replacement parts, list: Part Number, Description, Model Number and Series Letter.

LINCOLN provides a Distributor Network that stocks equipment and replacement parts.

Page 4 Form 403574