Prio Prio Jet X845 User manual

Prio®Jet

User’s Guide

Model X845

External Booster

Pump Box

with Auto Flush for

50-100GPD

Reverse Osmosis

Filtration Systems

Model X855

External Booster

Pump Box

with Auto Flush for

Direct Flow

(Tankless)

Reverse Osmosis

Filtration Systems

2

Before operating this unit, please read the instructions carefully. You may

want to save this guide for your future reference.

Safety Warning

Plug the unit into an electrical outlet only aer you nished the installation.

Check if the voltage indicated on the unit corresponds to the local mains

voltage before you connect the appliance.

Do not use the unit if it is damaged in any way. Take it to an authorized

service center for repair.

Do not open the unit. There are no serviceable parts inside.

When unplugging the unit from the mains, do not pull on the power cord.

Avoid touching the plug with wet hands.

Do not block air vents of the unit or place any items on it. Do not place

the unit near the sources of heat, radiators, etc. Do not place it in a tightly

closed space where it may overheat.

Keep the unit out of reach of pets or other animals.

In case of leakage malfunction or water presence around the unit shut

o the electrical power to the circuit rst, then pull the plug out of the

electrical outlet.

Remove the plug from the electrical outlet during your vacations or other

extended periods of time when the appliance is not in use.

Unplug the unit from the electrical outlet while servicing your water lter

system, and changing the membrane or lters.

Do not use the appliance if operating requirements such as water

temperature/water pressure/electrical supply, etc. are not met. Follow

other applicable regulations such as operating requirements for your

R.O. system. Note that the appliance contains the booster pump that

increases the line water pressure prior to the R.O. unit. Check if that

pressure is acceptable for your device.

Do not use the appliance with water that is microbiologically unsafe or of

unknown quality without adequate disinfection before or aer the system.

This appliance was not designed to be used with power cord extenders,

power lters, external transformers, outlet splitters, etc.

Never store or operate the appliance in direct sunlight.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities, or lack of experience

and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the unit.

At the end of its life, the appliance should be disposed of in an appropriate

manner.

Disposal

Old appliances still contain many recyclable materials. Therefore, please

take used unit to your retailer or recycling center so that it can be recycled.

3

Description

Congratulations on your purchase of the Prio® Jet booster pump box! Please familiarize

yourself with the general concept behind the product and main modes of operation.

Booster pump box models X845 and X855 were designed for 50-500 GPD rated Reverse

Osmosis water ltration systems for use in areas with low water pressure, or for users that

want maximum performance and the best quality ltered water from their R.O. systems.

Both models include the microcontroller and LED indicators for the hassle-free, fully

automatic operation and easy reading. They may be purchased separately to upgrade existing

compatible systems or be included in the high-end R.O. water ltration sets.

Model X845 is designed for 50-100 GPD rated R.O. units usually equipped with the water

collection container such as water pressure tank. Model X855 is designed for 150-500 GPD

rated R.O. machines, both direct ow (“tankless”) or with water tank.

Key Features:

Automatic ush valve: for peak performance and healthier membrane. 18 seconds of

powerful ush at the end of each water ltration cycle prevent the scale and debris build-

up on the membrane outer surface.

Powerful booster pump increases pressure to radically improve the performance

and eectiveness of the R.O. unit in all three key areas: increases ltered water ow

(production rate), increases rejection rate (improves water purication quality), increases

recovery rate (decreases amount of waste water).

Prolongs the membrane and pre-lter(s) service life due to increased recovery rate.

Fully automatic operation, no service necessary: plug and forget.

LED indicators: easily understand what the state of your R.O. unit is. Ever wondered

whether your tank is full or empty? No more guess!

Split, exible installation possible where needed: install the pump box up to 50 feet away

from the R.O. unit itself. Useful for the situations like lack of space or lack of electrical

outlet under the sink, or moving the unit to more appropriate place.

Idling protection: if you forget to close the ltered water faucet for a long time the pump

will shut down automatically for you.

Full separation of electrical components from the membrane and lters of the main R.O.

unit makes the regular servicing of your R.O. machine both easy and safe: no need to

worry about electrical valves and wires while changing your water lters or membrane.

Quick ttings for easy tube connections.

4

How It Works:

Aer the install use your R.O. unit as you normally would.

If your tank is not full the pump box will turn on automatically

and quickly ll it up with ltered water. Then it will ush the

membrane and shut o automatically. If you open the faucet

and take some ltered water from the tank the pump will

turn on automatically to rell the tank again.

For direct ow systems, just open the ltered water

faucet. The pump will turn on automatically and will

produce ltered water in real time until you close the

faucet. At the end of each water production cycle the

membrane will be ushed for 18 seconds, and then the

system will shut o automatically.

LED Indicators:

No Source: there is no water in the inlet line or it’s pressure is less than 7.25 psi (0.05

MPa). Make sure the inlet tube is connected and not kinked, and the water inlet valve is

open.

Working: the pump is working and connected R.O.machine is producing the ltered water

for you. Either tank is not full yet or ltered water faucet is open. No action is required.

Ready: ltered water faucet is closed and tank (if installed) is full. The pump is o. No

action is required.

Flush: 18 s membrane ush is going. No action is required.

Reset: idling protection was triggered. The pump is o. To restore normal operation

power cycle the unit.

Pressure Switches:

The unit is equipped with low and high pressure switches. The low pressure switch shuts o

the pump when there is no inlet water or its pressure is too low. The high pressure switch

shuts o the pump when the ltered water faucet is turned o and tank is full (if installed) and

high back pressure of the ltered water line is built.

Pump:

The unit is equipped with the low voltage booster pump powered by the included transformer

for safe operation.

Precaution:

Please do not use the model X855 with R.O. units equipped with low-production membranes

of ow rating less than 150 GPD. Also, your membrane should be “true” thin lm composite

R.O. membrane, not nano-membrane. The latter is usually identied by word ‘Nano’ or ‘LP’ or

‘ULP’ in the membrane model description. ULP/Nano membranes may be damaged overtime

by powerful pump of X855. Consult your service provider for proper type of R.O. membrane.

Upgrade your membrane if necessary.

Model X845 can be used with both R.O. and ULP/Nano membranes of 50-100 GPD rating.

Neither model is suitable for ultra-ltration (UF) systems.

5

Direct Flow R.O. Systems Benets:

Model X855 makes it possible to build high-end direct ow R.O. machines that oer best in

class performance and water quality.

Freshness of water ltered in real time. No more stale water from a tank.

Virtually unlimited ltered water production. While conventional systems with tanks are limited

by the tank and require prolonged timeouts to rell the tank, a direct ow system is limited by

the membrane ltration rate only. It is also easily scalable by upgrading the membrane.

Instant and sustained ltered water ow. It doesn’t depend on how full the tank is. This is

particularly important for commercial applications too. No more waits for tank rell either.

Space-saving, compact installation since tank is not needed.

Better water purication quality due to improved contaminant rejection rate.

Typically, up to three times less water is wasted per gallon of ltered water due to high

recovery rate as compared to classical tank systems. Saves you money and Planet Earth’s

water resources!

Lower cost of ownership due to prolonged service life of pre-lters and membrane, which

is in turn a result of higher eciency rate: less water is treated overall by pre-lters and

the membrane for each gallon of permeate produced. This saves the capacity of pre-lters

and ensures either less frequent change necessity or better purication.

Less number of components leads to better reliability.

Specication

Operating Requirements:

Minimum inlet water pressure: 7.25 psi (0.05 MPa)

Maximum inlet water pressure: 61 psi (0.42 MPa) / 80 psi (0.55 MPa) when used together

with select Prio® R.O. units

Minimum water temperature: 41 oF (5 oC)

Optimal water temperature: 59–77 oF (15–25 oC)

Maximum water temperature: 95 oF (35 oC) / up to 105 oF (40.5 oC) short-term

Ambient air temperature: 41–105 oF (5–40.5 oC). Indoor use only.

Water source: tap water supply, chlorinated or non-chlorinated, bacteriologically safe

Supply water pH range: 4.0-11.0

Supply water turbidity: < 1 NTU

Supply water components: Hardness (CaCO3) <180 mg/L (<10.5 gpg), Iron <0.1 mg/L,

Manganese <0.05 mg/L, Hydrogen Sulde 0.00 mg/L

Maximum supply water TDS: 1000 ppm

Electrical input: AC 100-240V 50/60 Hz

Maximum length of the line between the unit and the membrane (“split installation”): 50

(15 m) (purchase of extra tubing may be required)

Tubing: ¼”

Weight and Size:

Size (WDH), body only, excluding protrusions: 8.74 x 4.80 x 12.44” (222 x 122 x 316 mm)

Weight, without water and tubing:

8.2 lbs (3.7 kg) for X845;

8.6 lbs (3.9 kg) for X855

6

Performance Guidelines:

Performance of the appliance such as pressure boost or ow rate of the connected R.O. unit is

highly dependent on local conditions (inlet water pressure, temperature and TDS, R.O. membrane

type and ow rating, R.O. unit type and its design specics) and R.O. system use pattern.

Typical pressure boost (

∆

P, extra pressure built upon the inlet pressure) is up to 50 psi

(0.34 MPa) for 50-100 GPD R.O. membrane for X845, and up to 100 psi (0.69 MPa) for

150-500 GPD membrane for X855. For example, the higher the GPD rate of the membrane

attached or the higher the water temperature the lower is an actual pressure boost for

a given setup but the higher the output ow rate in working mode. Typically, in working

mode outlet water pressure reaches 80-110 psi for X845 and 110-160 psi for X855

depending on local conditions and membrane used.

Drain water ow restrictor: 300 cc (ml/min) nominal, up to 450 cc in working mode, open

ow in ush mode.

Auto-ush duration: 18±10% s

Idling protection: 120 minutes (the unit will shut-o the pump and goes into ‘reset required’

mode if working mode continuous duration reaches 2 hours without interruption)

Warranty:

1 year limited warranty

Package Contents:

(1) The auto-ush booster pump box unit

(20 / 6 m) Water tubing ¼”

(1) ¼” x ¼” x ¼” union tee quick tting

(1) ¼” x ¼” union check valve

User’s guide

Installation

Notes:

1. Install your R.O. machine rst. Usually, steps include: inlet valve installation, drain saddle

installation, ltered water faucet installation, tank and tank valve installation, etc. See your

R.O. machine manual for the detailed instructions. Do not open inlet valve until you nish the

unit setup. If you used your R.O. machine before close the inlet valve and drain the water tank

(by opening the ltered water faucet).

2. If your R.O. machine includes ow restrictor, 4-way shut o valve, manual ush valve

remove them on the R.O. unit itself. Built-in components of the pump box will be used instead.

See the following charts for proper connection scheme.

3. Use of air gap faucet is not recommended in R.O. systems with powerful auto ush feature

due to high ow of waste water during the ush. If you have air gap faucet you may simply not

use its waste line and insert waste water tubing directly into the drain saddle (bypassing the

air gap). You may want to use a check valve (optional) on the drain line then to obtain same

protection from a drain water backset as air gap provides.

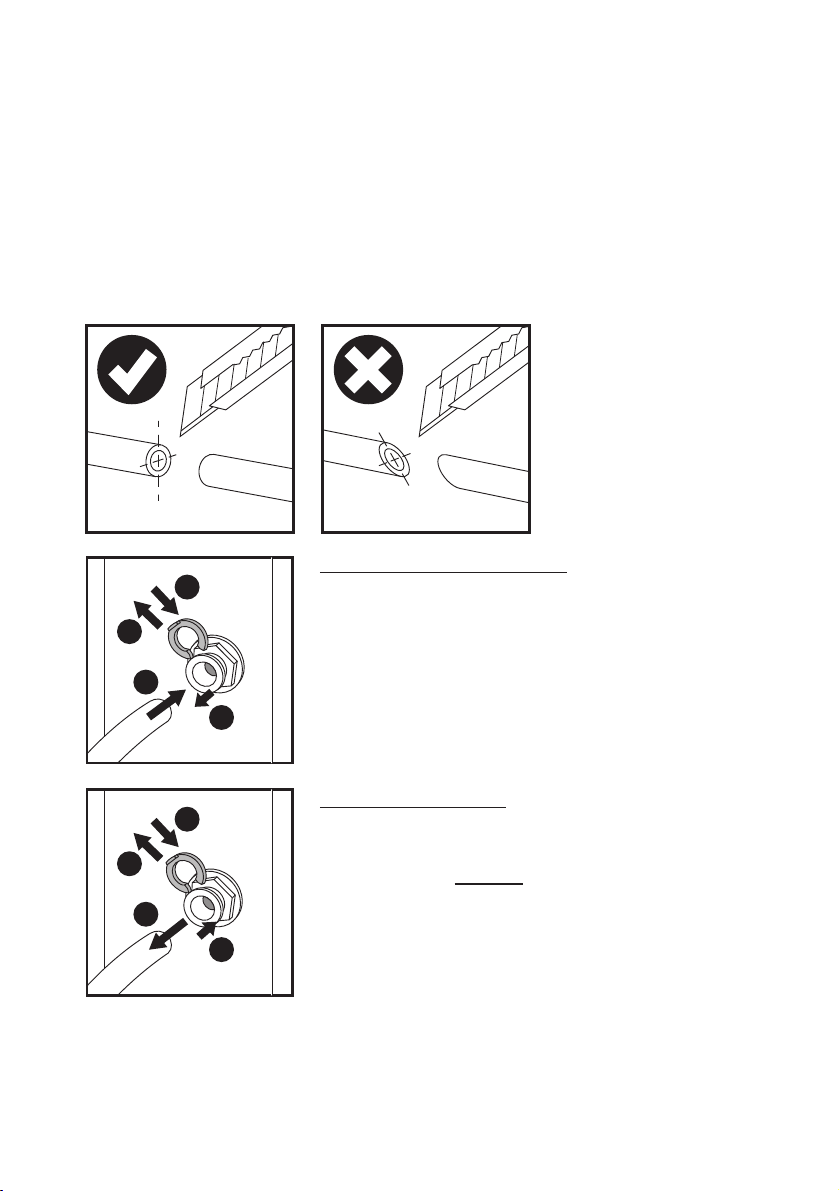

4. During installation you will need to cut the supplied ¼” tubing into segments as needed.

Use your utility knife for that or similar tool. See the following charts to determine the

7

connection scheme and length of hoses necessary. You may need to purchase extra tubing

for far-reaching split or other corner case installations.

5. It is recommended to connect the unit between the nal pre-lter and the membrane if

your R.O. machine design permits such connection. It protects the pump and helps avoiding

the unneeded pressure on pre-lter(s). Otherwise connect the unit prior to your rst pre-lter

(5 micron PP sediment in-line lter or equivalent is still recommended prior to the unit; point-

of-entry sediment lter works just ne for this purpose).

6. Do not connect the unit to the electrical supply until the Setup is completed.

IMPORTANT: Cut tubing at 90 degrees to ensure a watertight seal:

To Connect the Tubing to a Fitting:

1. Remove the lock if present (not present in self-locking

ttings).

2. Push. Insert the tube rmly until full stop.

3. Pull the collet back slightly.

4. Replace the lock (if present).

To Disconnect the Tubing:

1. Remove the lock if present (not present in self-locking

ttings).

2. Push the collet and hold.

3. Pull the tubing out.

4. Replace the lock (if present).

1

4

3

2

1

4

2

3

No skewed cut!

8

Unit Placement Guide:

Hose Connections:

Important: if your R.O. machine includes 4-way shut o valve (control valve), ow restrictor,

manual ush valve remove them on the R.O. system itself. The unit’s internal components

will be used to provide the same or enhanced functionality. The unit is not compatible with

R.O. systems with built-in (non-removable/non-bypassable) control valve or ow restrictor.

1. Insert water supply tubing from nal pre-lter into the “inlet” tting of the unit.

2. Insert the supply tubing from the “RO unit” tting of the unit into the supply inlet of the

membrane housing.

3. Insert the ltered water tubing from the ltered water outlet of the membrane housing

into the “permeate” tting of the unit. Use included extra union tee tting if needed.

4. Insert the waste tubing from the waste water outlet of the membrane into the “waste”

tting of the unit.

5. Insert the waste tubing from the “drain” tting of the unit into the drain saddle (optionally

through the union check valve or through the air gap faucet on the way) or to a waste

water collection container.

See the following charts for details.

9

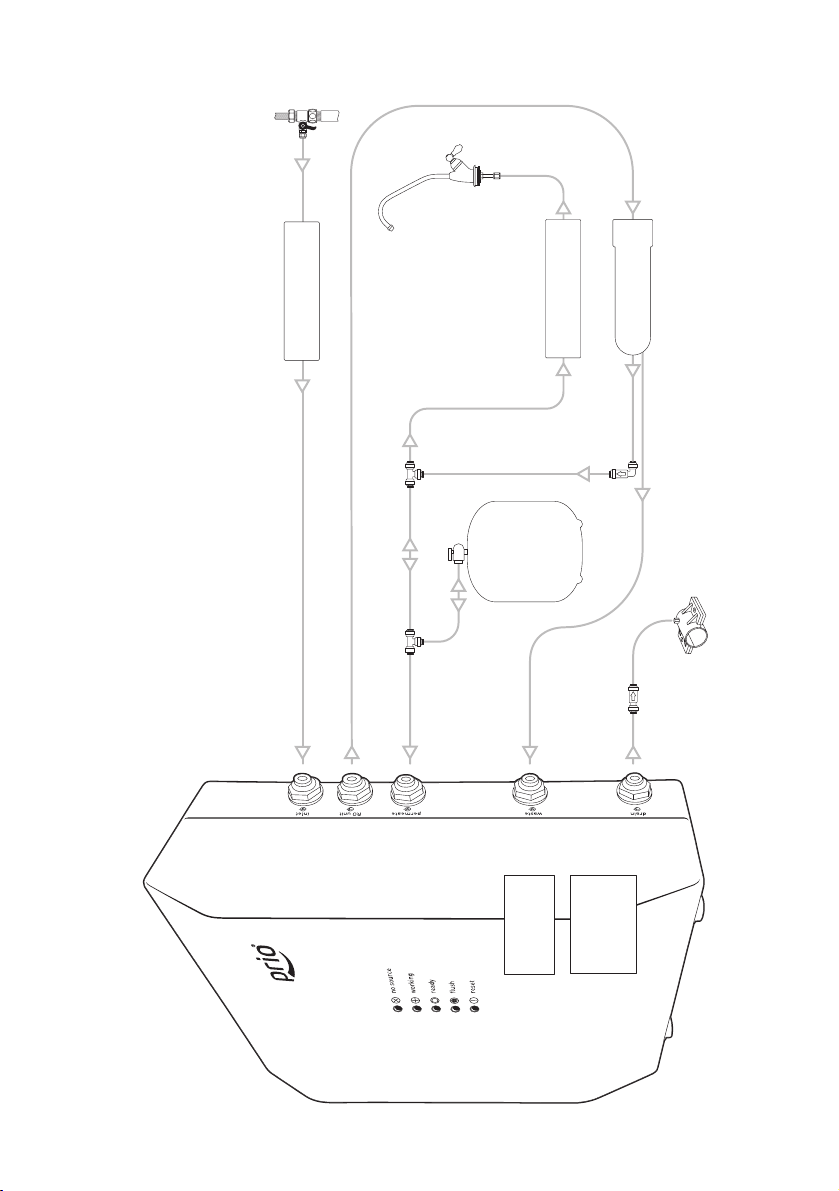

inlet

valve

filtered

water

faucet

membrane supply inlet

from final pre-filter

post-filter

check

valve

tank

drain saddle

permeate

(center outlet)

waste (side outlet)

union tee

fitting

pre-filter(s)

X845

X855

with tank

tank

valve

union tee

fitting

General R.O. System with Tank Connections

from final pre-filter outlet

to supply inlet of the membrane

from filtered water outlet of the membrane

from waste water outlet

of the membrane

to drain or

waste water

collection container

check valve

(optional)

membrane

10

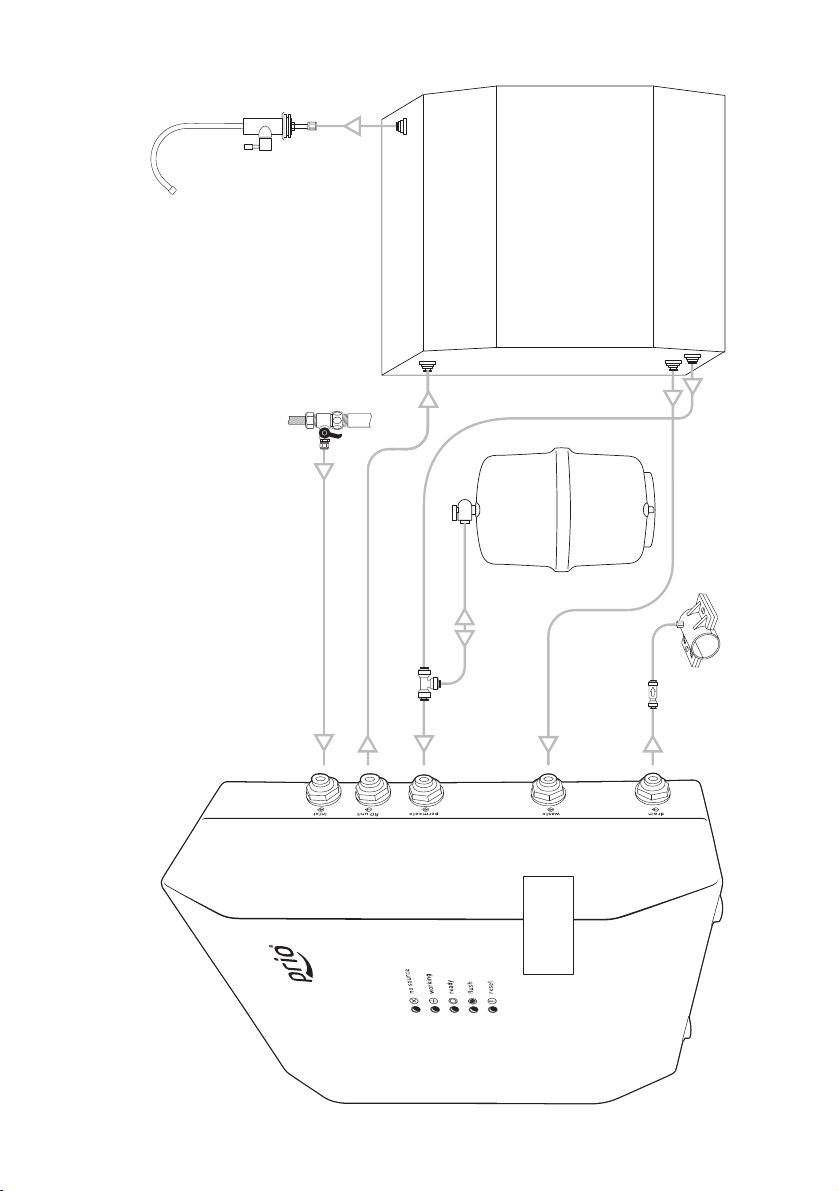

inlet

valve

filtered

water

faucet

from final pre-filter

pre-filter(s)

membrane supply inlet

high-production

membrane

post-filter

check

valve

drain saddle

union tee

fitting

X855

direct flow

General Direct Flow R.O. System Connections

from final pre-filter outlet

to supply inlet of the membrane

from filtered water outlet of the membrane

from waste water outlet

of the membrane

to drain or

waste water

collection container permeate

(center outlet)

waste (side outlet)

check valve

(optional)

11

X845

Prio® Expert MO600 R.O. System Connections

drain saddle

R.O. unit

inlet

MO600

tank

inlet valve

waste water outlet

permeate outlet to the tank

union tee fitting

from waste water outlet

of the membrane

to drain or

waste water

collection container

check valve

filtered

water

faucet

from inlet valve

to R.O. unit inlet

from filtered water outlet of the R.O. unit

12

X855

Prio® Expert MOD600 Direct Flow R.O. System Connections

waste water outlet

permeate outlet

R.O. unit

inlet

inlet

valve

drain saddle

MOD600

filtered

water

faucet

from inlet valve

to R.O. unit inlet

from filtered water outlet of the R.O. unit

from waste water outlet of the R.O. unit

to drain or

waste water

collection container

check valve

(optional)

13

OD360

pre-filter

post-filter

pre-filter

inlet

post-filter

inlet

filtered

water

faucet

inlet

valve

drain saddle

check

valve

membrane

union tee fitting

pre-filter

outlet

waste water

outlet of the

membrane (side)

permeate

outlet of the

membrane

(center)

membrane

inlet

X855

Prio® Expert OD360 Direct Flow R.O. System Connections

from final pre-filter outlet

to supply inlet of the membrane

from filtered water

outlet of the membrane

from waste water outlet

of the membrane

to drain or

waste water

collection container

check valve

14

Initial Washing:

Aer installation it is recommended to perform the initial washing of the unit and connected

R.O. system.

For this, for R.O. systems with tank:

close the tank valve;

open the inlet valve;

open the ltered water faucet;

plug the unit’s power cord into the electrical outlet;

wait for water to arrive at the faucet (it may take a while, water ow usually is not high,

water foam and air may be going out of the system);

wait 1-2 minutes for more or less steady (yet usually low) water ow from the faucet and

close the faucet;

wait for auto ush to complete (18 s);

repeat steps “open faucet – wait 1-2 minutes – close the faucet – wait for auto ush to

complete” at least 5 times;

aer you nished with previous step close the faucet and open the tank valve;

wait for the tank to ll to full (until “ready” LED indicator lights up) then drain the tank

completely by opening the faucet;

you may repeat the tank full rell – tank drain once again;

aer you close your faucet the tank will rell again, and your system is ready for use.

For direct ow R.O. system:

open the inlet valve;

open the ltered water faucet;

plug the unit’s power cord into the electrical outlet;

wait for water to arrive at the faucet (it may take a while, water foam and air may be going

out of the system);

wait 2 minutes for more or less steady water ow from the faucet and close the faucet;

wait for auto ush to complete (18 s);

repeat steps “open faucet – wait 2 minutes – close the faucet – wait for auto ush to

complete” 5-10 times;

aer you nished with previous step close the faucet, and your system is ready for use.

Please note that aer initial installation of the unit and/or R.O. machine or changing the

lters or membrane, air contained in the new dry system or lter may come out sometimes

producing foamy, white ltered water. Water may look white due to tiny air bubbles in it. If you

leave the water to stand for few minutes all bubbles will surface and eliminate. Such aerated

water is clean and safe. Gradually over the coming days all air inside your system will nd

its way out. To make this process faster you may repeat the initial washing procedure until

you’re pleased with the result. Also note that if for some reason the water supply contains a

lot of dispersed air, your R.O. machine may start producing aerated water again. The unit’s

internal pipes and components never take air from outside as they are completely air and

water sealed and leak-free.

15

Regular Use

Aer the installation use your R.O. unit as you normally would.

If your tank is not full the unit will turn on automatically and ll it up with ltered water. Then

it will ush the membrane and shut o automatically. If you open the faucet and take some

ltered water from the tank the pump will turn on automatically to rell the tank again.

For direct ow systems, just open the ltered water faucet. The pump will turn on

automatically and will produce the ltered water ow in real time until you close the faucet.

At the end of each water production cycle the membrane will be ushed, and then the system

will shut o automatically.

Please note that R.O. membranes (especially dry ones) need up to 50 hours of active operation

before they reach peak performance in terms of water ow, recovery and rejection rates.

For your safety and peace of mind please unplug the unit from the electrical outlet and close

the inlet valve before servicing your R.O. system such as changing the lters or membrane,

or during vacations.

Prio, Prio logo are the trademarks of DWT Deutsche Wassertechnologien GmbH, Germany.

As used herein, ® denotes registered trademark status in Germany only.

Copyright © DWT Deutsche Wassertechnologien GmbH, Germany, 2014, 2018

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

GORMAN-RUPP PUMPS

GORMAN-RUPP PUMPS 112D60-B Installation, operation, and maintenance manual with parts list

WOERNER

WOERNER GMF Translation of the original operation manual

Flotec

Flotec SCM 4 PLUS Series Use and maintenance manual

Pentair

Pentair CRISTAL-FLO II Installation and user guide

LEYBOLD

LEYBOLD EcoDry - M Series operating instructions

Gardena

Gardena 8200 Operator's manual