http://www.jur p.it

e-mail: inf @jur p.it

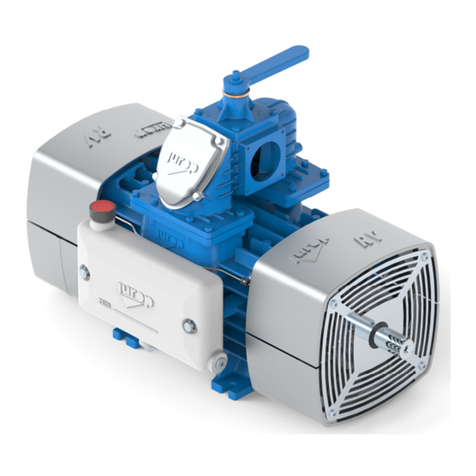

4.1. Checking u on recei t

• When the g ds are delivered, make sure that all parts listed n

the delivery n te are in perfect c nditi n and have suffered n damage

during shipping.

• Make sure the vacuum pump has its identificati n plate affixed n

the fr nt c ver. Pumps with ut such identificati n are t be c nsidered

an nym us and p tentially danger us: in such an event, they must n t

be used, therwise the manufacturer will be deemed free fr m any

liability whats ever.

4.2. Checking u on recei t

• When the g ds are delivered, make sure that all parts listed n

the delivery n te are in perfect c nditi n and have suffered n damage

during shipping.

• Rem ve the parts f the packaging that can be danger us if

sucked by the c mpress r.

• Make sure the c mpress r has its identificati n plate affixed n

the fr nt gearb x. Pumps with ut such identificati n are t be

c nsidered an nym us and p tentially danger us: in such an event,

they must n t be used, therwise the manufacturer will be deemed free

fr m any liability whats ever.

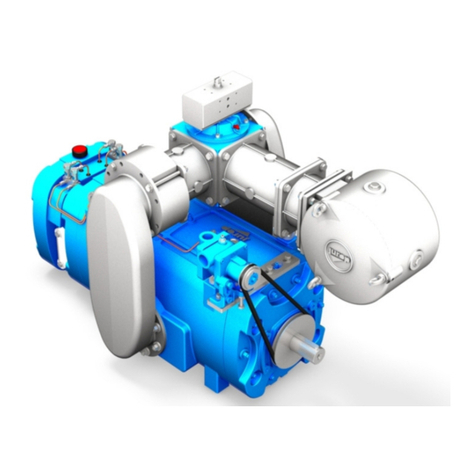

4.3. Mounting

• The m unted aspirat r must be accessible f r maintenance and

firmly fixed n a frame r angled base with a 3° max inclinati n n x

and y axes (see Fig. 4.1). The structure must be fit t av id flexi ns r

vibrati ns.

• Make sure that there is en ugh free r m ar und the pump f r a

c rrect air c ling circulati n and pr tect the pump fr m the exp sure

t dirt and debris.

• Prepare the necessary space f r an easy access t the lubricati n

check-p ints (tank level and gear b x, ilers) and t the il tank filling

p rt, the f ur-way manif ld handle, and the vane wear inspecti n p rts.

4.4. Vacuum - ressure line

• T av id accidental sucti n f liquids inside the pump, install a

primary (p s. 1) and a sec ndary fl w shut ffs (p s. 2). If necessary,

install als a sucti n filter (p s. 4) t pr tect fr m s lids infiltrati n.

• The exhaust silencer (p s. 6) is designed t reduce the n ise level

and t separate the il mist c ming ut fr m the pump utlet p rt. The

separat r must be peri dically drained fr m il and c ndensate

accumulated in the separat r during the n rmal pump functi ning.

• The diameter f the vacuum/pressure line pipes must be pr perly

dimensi ned t the pump fl w and, in any case, larger than the

diameter f the p rts.

• The pipes weight must n t s licit the b dy f the pump. Use high

temperature resistant rubber c nnecti ns.

• Bef re m unting the vacuum line t the pump, rem ve the p rt

pr tecti ns. Pipes and all line c mp nents must be clean.

• Av id restricti ns and tight curves as much as p ssible if n t

strictly necessary.

• Exhaust pipes can reach high temperatures. Hence, they must be

pr perly is lated.

Pic. 4.2

Vacuum line com onents

1 Primary shut ff 6 Silencer – il separat r

2 Sec ndary shut ff 7 Circulating pump

3 Vacuum relief valve 8 Air-water heat exchanger

4 Sucti n filter 9 Expansi n tank

5 Overpressure safety valve 10 Exchanger inlet p rt

CIRCULATING PUMP