4

IMPROPER AND UNSAFE USE OF THE COMPRESSOR CAN RESULT IN DEATH OR SERI-

OUS INJURY. IT IS VERY IMPORTANT THAT THE INTENDED OPERATOR OF THE COM-

PRESSOR READS AND UNDERSTANDS THIS MANUAL BEFORE OPERATING THE

COMPRESSOR. KEEP THIS MANUAL AVAILABLE FOR OTHERS BEFORE THEY USE THE

COMPRESSOR.

Please keep this manual in safe place for future reference.

Important safety information

The manufacturer cannot possibly anticipate every possible circumstance that might involve a hazard. The warn-

must make sure that it is safe for you and others. You must also make sure that the procedure, work method, or

operating technique that you choose does not render the compressor unsafe.

Figures

Table of content

............................................................................................................................. 4

Figures ............................................................................................................................................................... 4

.................................................................................................................................... 5

Tool application.................................................................................................................................................. 5

Declaration of conformity .................................................................................................................................. 5

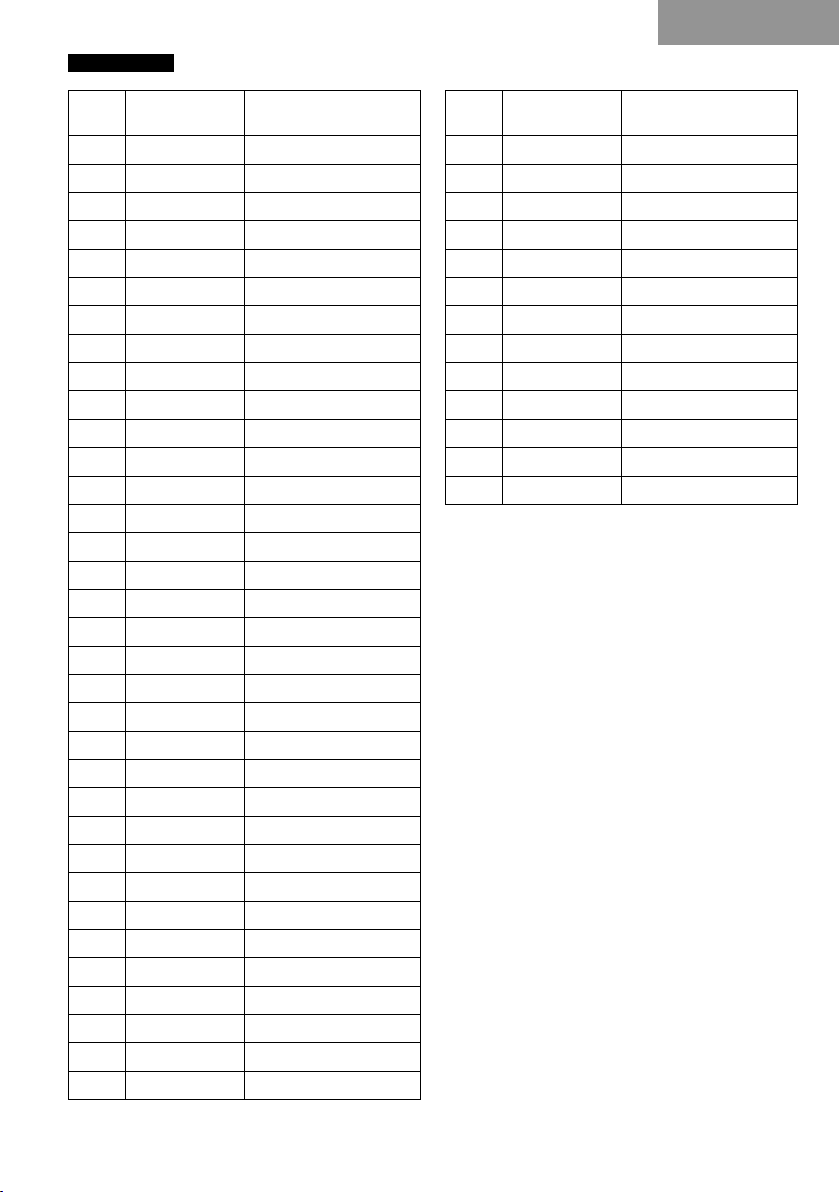

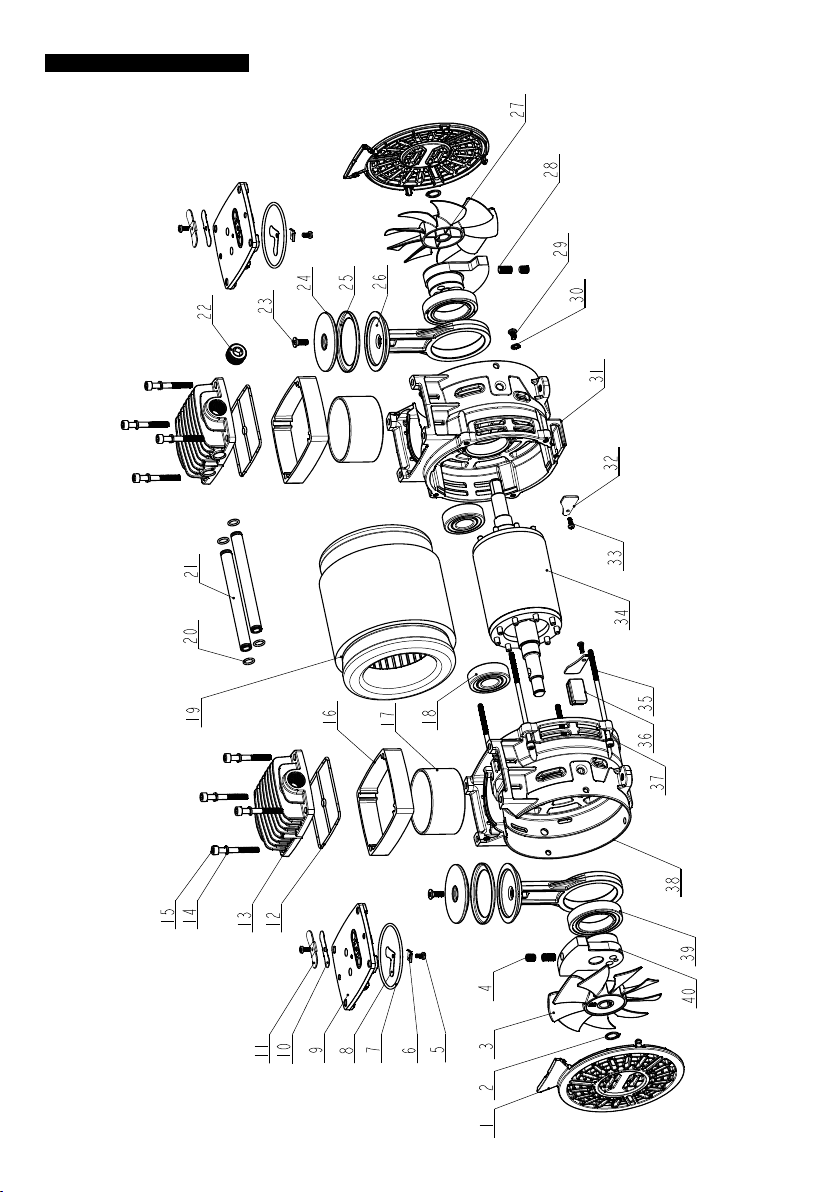

Explode drawing ................................................................................................................................................ 6

Spare parts ........................................................................................................................................................ 7

Explode drawing - motor.................................................................................................................................... 8

Spare parts - motor............................................................................................................................................ 9

Explanation of symbols.................................................................................................................................... 10

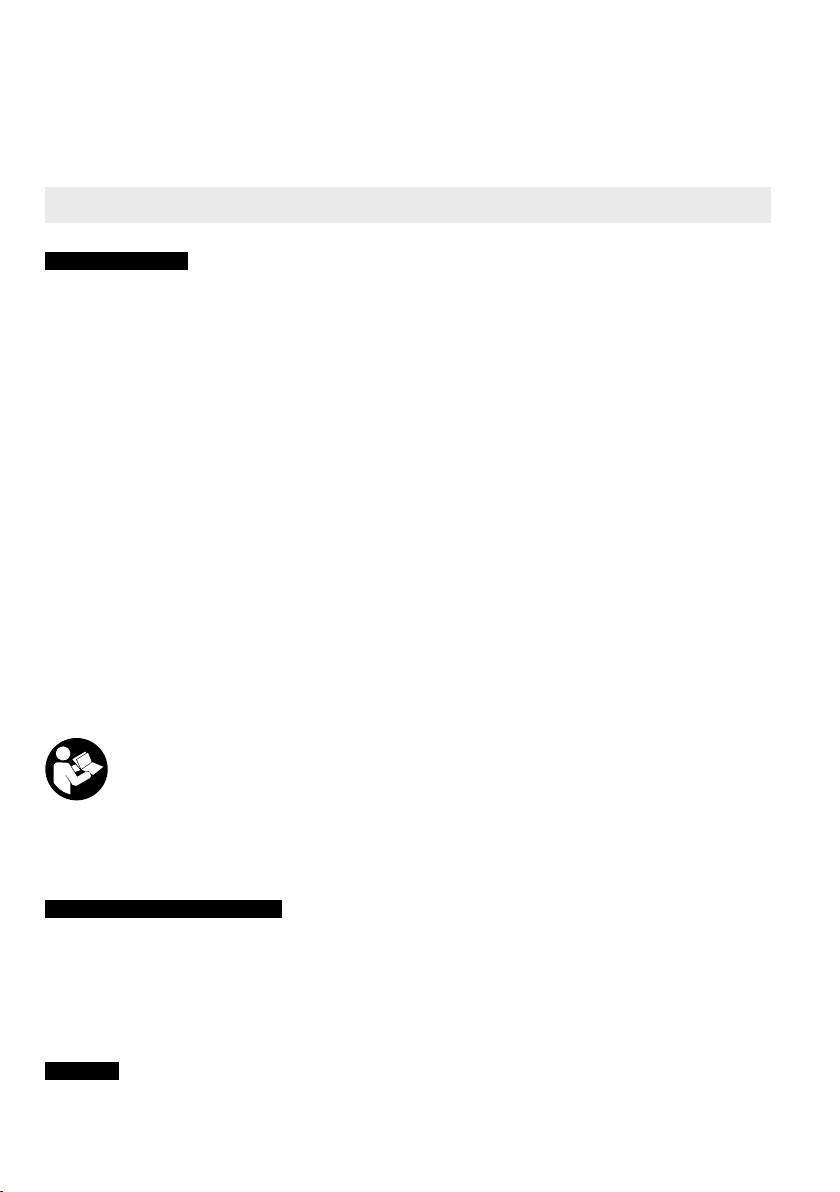

Key parts ...........................................................................................................................................................11

General safety warnings...................................................................................................................................11

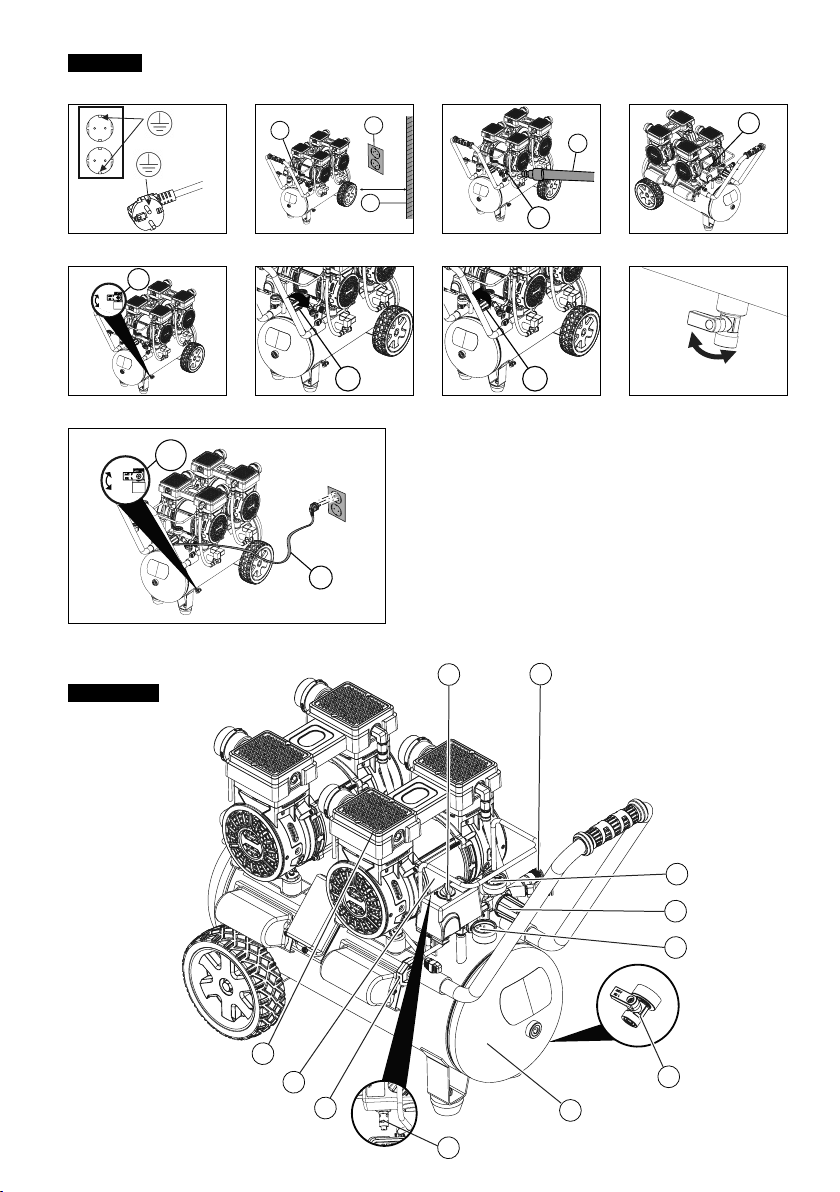

Assembly instructions.......................................................................................................................................12

Positioning of the air compressor ................................................................................................................12

Connect air hose to compressor..................................................................................................................12

Operating instructions ......................................................................................................................................12

Break in the pump ........................................................................................................................................12

Before each start-up.....................................................................................................................................12

How to start ..................................................................................................................................................12

How to shut down .........................................................................................................................................12

Maintenance .....................................................................................................................................................13

How to drain tank..........................................................................................................................................13

Storage .........................................................................................................................................................13

Trouble shooting ...............................................................................................................................................14

ORIGINAL INSTRUCTIONS

BYGMA COMPRESSOR 3.0HP OIL-FREE