C & K Systems FG-1025Z User manual

- 1 -

FEATURES

•Advanced microcontroller

with Digital Signal Process-

ing (DSP)

•Precise 160oprotected and

160oexcluded zones

•Dual microphones with

time-of-arrival (TOA)

processing

•Continuous self-test

•No adjustments

•No minimum range

•RemoteTestModeactivation

with FG-701 simulator

•End-of-line / spare terminals

WIRING (Continued)

Glass-Break Detector

Model FG-1025Z

INSTALLATION

INSTRUCTIONS

•Cover and wall tamper

•Selectable Alarm Memory

•LED enable

•8 - 14 VDC operation

•Energized Form C relay

•PCB and housing designed

to protect against ESD and

mechanical damage

•Watchdogfor microcontroller

•GreeneventLEDlightswhen

sounds are processed

•Dedicated trouble output

•Selectable Command Input

or Remote LED Enable

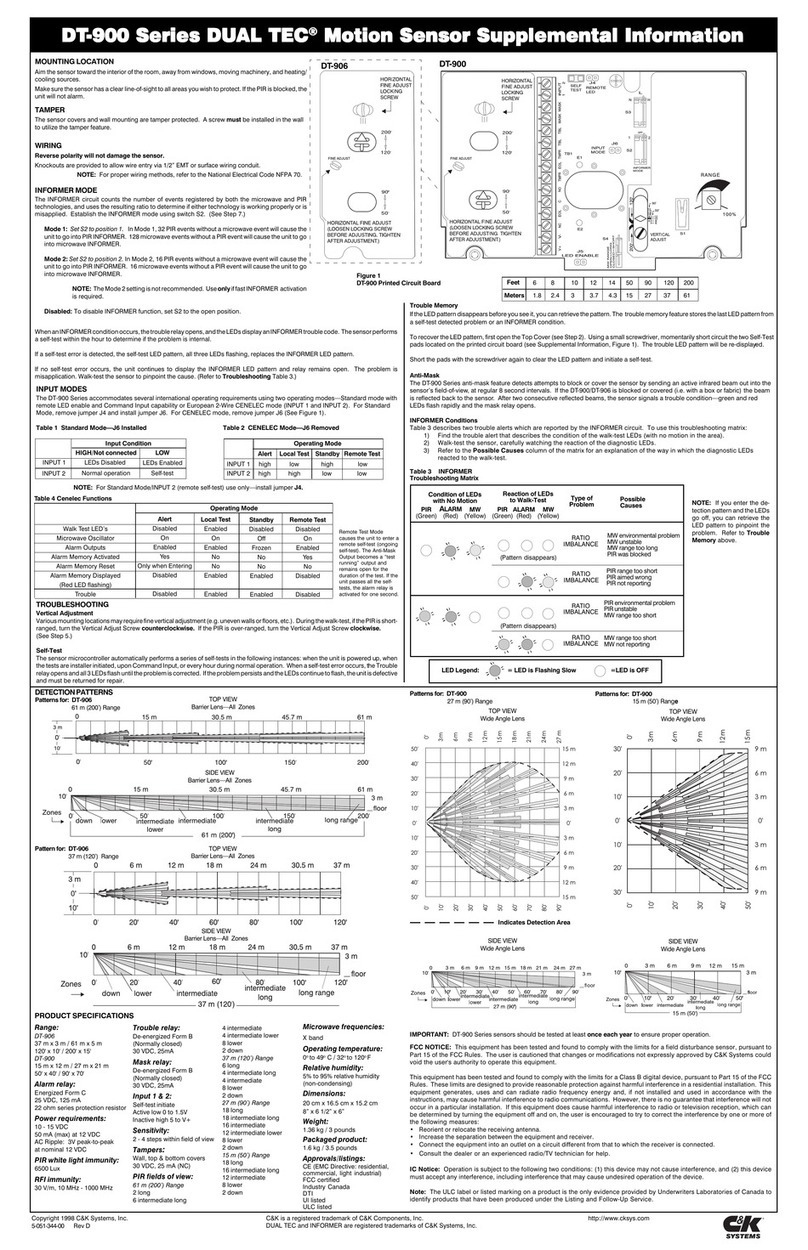

Figure 2b

Wiring for a

N.O. loop, no

EOL resistor

Figure 2c

Wiring for a

N.C. loop with

EOL resistor

Figure 2d

Wiring for a

N.O. loop with

EOL resistor

Figure 2

WIRING

Figure 2a

Wiring for a

N.C. loop, no

EOL resistor

PRODUCT DESCRIPTION

The FG-1025Z is a directional glass-break detector. Two

microphones and time-of-arrival processing allow the unit to

provide precisely-defined protected and excluded zones.

For a detailed description of how the FG-1025Z works, refer to

the Technical Information section on page 5.

MOUNTING LOCATION

For the greatest flexibility in aiming the FG-1025Z, mount the unit

on the ceiling. Figure 3 illustrates the protected, excluded and

keepout zones for a ceiling mounted FG-1025Z.

The arrows printed on the intermediate cover (see Figure 1)

indicate the direction of the protected zone. Refer to the

Mounting Guidelines to select an appropriate location, and refer

to the Aiming Guidelines to aim the unit properly. (If ceiling

mounting is not possible, the unit can be mounted on a wall or post.)

WIRING

1. For surface-wired installation, use optional Wiring Spacer

Plate (model number FG-SP2).

2. Route wire through Wire Entry Hole in the center of the

printed circuit board (PCB), and strip wire ends 1/4" (6.5 mm).

3. Wire the unit as shown, (use 22 - 18 AWG). Reverse polarity

connections will not damage the unit.

4. When wiring is complete, push excess wire back into the

ceiling. (Refer to the Mounting Locations section.)

NOTE: If end-of-line resistors are required, wire as shown in Figures

2c and 2d.

LEDs

Alarm

Form C

125 mA max

25 VDC max

Power

25 mA at

12 VDC

DIP Switch

Terminal

Blocks

Wire

Entry

Hole

Command Input

Active low (0-1.5V);

or Remote LED

Select function

at S2-3

Tamper Switch

FrontMicrophone

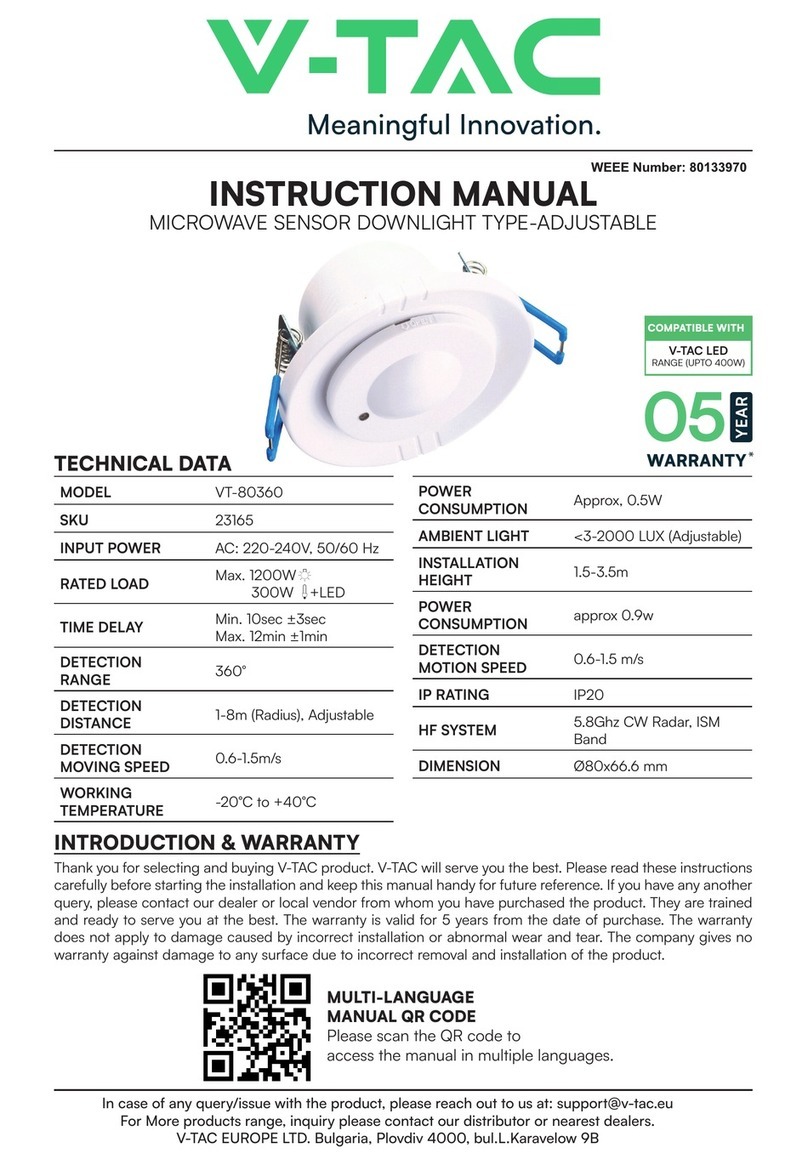

Figure 1

Back

Microphone

Tamper

25 mA max

24 VDC max

Trouble

Output

Open

collector

1K series

resistor

Keepout

Zones

SYSTEMS, Inc.

- 2 -

MOUNTING LOCATION (Continued) MOUNTING PROCEDURE

NOTE: If you plan to use the ceiling/wall tamper, locate the position

of the ceiling/wall tamper screw before locating the mounting screws.

(Refer to Tamper Switch section.)

1. To open the sensor, use a screwdriver to push down on the

latch through the slot on the side of the unit. (See Figure 4.)

NOTE: The FG-1025Z is designed to be mounted without removing

the PCB. DO NOT remove the PCB from the protective enclosure.

2. For mounting the FG-1025Z sensor, #6 (M 3.5) or #8 (M 4)

screws are recommended. (Screws are not provided.)

3. If surface wiring is required, use the optional Wiring Spacer

Plate (model number FG-SP2).

Figure 3

TOP VIEW

25' Radius

160o

PROTECTED

ZONE

160o

EXCLUDED

ZONE FG-1025Z

20o Keepout ZoneKeepout Zone 20o

SIDE VIEW

20o

FG-1025Z

PROTECTED

ZONE

25' Radius EXCLUDED

ZONE

Keep-

out

Zone

Aiming Guidelines:

•Orient the unit so that all protected glass is within the

protected zone and all known false alarm sources are within

the excluded zone. (Refer to Figure 3.)

•Aim the unit so that no protected glass is in the keepout

zones. Sounds in the keepout zone may or may not be

processed. (However, false alarm immunity is at least as

good in the keepout zones as it is in the protected zone.)

• Verify the edges of the protected zone by using the FG-701

simulator, hand claps, or any sharp sound. If the sound source

causes the green LED to flicker, the sound is being processed.

(The LEDs must be enabled.)

•Before mounting the unit, refer to the Testing section to help

determine the best location.

Tip: It is a good idea to mount the unit temporarily in the intended

location and power it with a 9 V battery until aiming and testing have

established proper detection. If the 9 V battery cannot supply

sufficient power, the unit will not operate.

Mounting Guidelines:

•Mount the unit close to, and within 25' (7.6 m) of the pro-

tected glass.

As much of the room as possible should be in

the excluded zone.

•There is no minimum range, but the unit must have a clear

line-of-sight and a clear view of the protected glass.

•The preferred location is on the ceiling directly opposite the

glass.

• Do not mount in corners, and keep the unit at least 1' (0.3 m)

from any adjacent walls.

•When wall mounting, mount the unit at a height of at least 6 feet

(1.8 m) to avoid accidental screening if furniture in the room is

moved.

• There should be no obstructions on the mounting surface

within 6" (15 cm) of the microphone openings.

•The FG-1025Z will detect through venetian blinds and light

drapes.

Test the location thoroughly whenever there are

window coverings present.

•Do not mount within 3 feet (0.9 m) of forced air ducts, sirens,

or bells measuring two inches (5 cm) or more in diameter.

•Be sure to test the unit for detection in the final mounting

location.

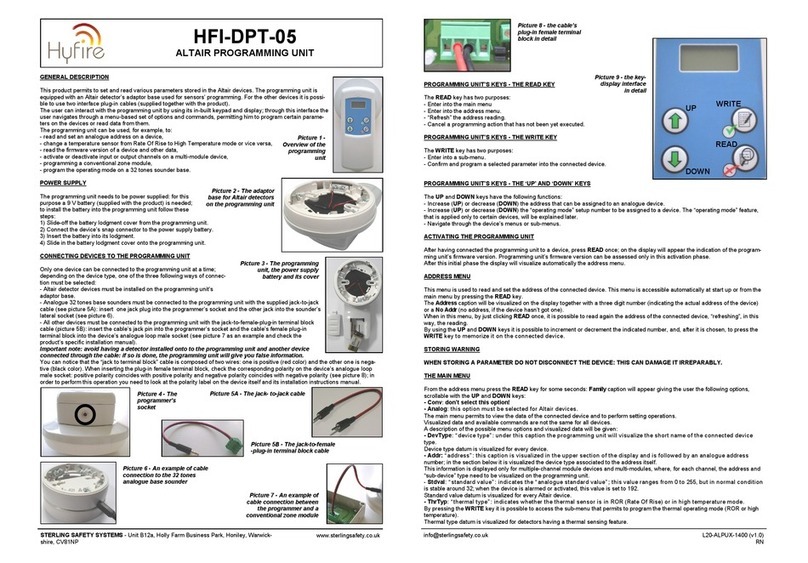

Optional Wiring

Spacer Plate

(FG-SP2)

Front Cover

Microphone

Hole

Optional

Cover Screw

Breakout Flash

Press in on

this latch to

open the unit

Back Cover

#6 or #8

Mounting Screw

(M 3.5 or M 4)

Note: If required,

the front cover can

be secured with a

screw after

installation. Break

out the cover

screw breakout

flash, and secure

the front cover with

a #4 (M 3) screw.

TAMPER SWITCH

The FG-1025Z is equipped with a combination normally-closed

(NC) cover and ceiling/wall tamper. Each unit is shipped with the

cover tamper operational and the ceiling/wall tamper disabled.

To use the wall tamper:

1. Use needle-nose pliers to break out the plastic tab on the

back of the unit. (See Figure 5.) The ceiling/wall tamper arm

will then extend through the hole.

2. The ceiling/wall tamper screw (not provided) should be a flat-

head #8 (M 4) or #10 (M 5) screw.

3. Install the ceiling/wall tamper screw so that it will just make

contact with the bottom of the tamper cavity when the unit is

mounted. (Refer to Figure 6.)

4. After installing the ceiling/wall tamper screw, position the unit

over it and mark the locations for the mounting screws.

The sensor may also be

mounted on the hole

pattern with #8 (M4) self-

tapping screws

Figure 4

- 3 -

Back

Cover

Breakout

Tab

Figure 6

TAMPER SWITCH (Continued)

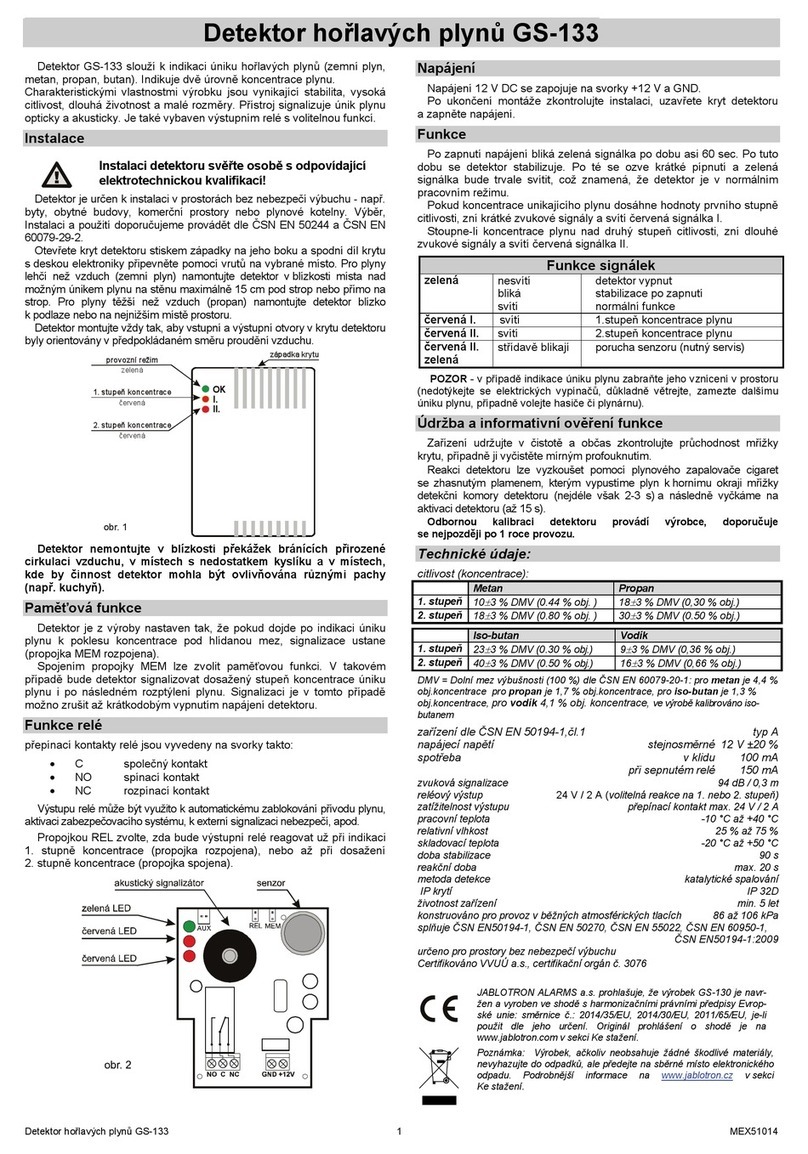

CMD IN / REMOTE LED INPUT

Use DIP switch S2-3 to select the function of the control input at

terminal strip TB2. Designate the input as a Command Input or a

Remote LED Enable. The input circuit is shown in Figure 7.

•

As Command Input:

a logic low signal will initiate a complete

self-test sequence. If the test fails, the Trouble Output will be

activated.

•

As a Remote LED Enable:

A logic low signal will enable both

LED's. The manual LED enable at DIP switch S2-2 must be

OFF.

Note: If not used, you can leave the input unconnected.

FG-1025Z CONFIGURATION (Continued)

Tamper

Cavity

.385 in

(9.78mm) #8 or #10

Screw

(M 4 or M 5)

Rear

Housing

Install screw to seat in tamper

cavity

Figure 5

Figure 7

Command/Remote

LED Input Circuit

High-Impedance

10K

+5V

100K

+5V

ACTIVE LOW

INPUT LOW:

INPUT HIGH: 3.5-5V

0-1.5V

TB2

CMD-IN/

Remote LED

Terminal

TROUBLE OUTPUT

Failure of a power-up or periodic self-test is signaled by a logic

high output at the Trouble Output terminal on TB2. The output

will be held high until a subsequent self-test passes. The output

circuit is shown in Figure 8.

FG-1025Z CONFIGURATION

Configure DIP switch S2 to best suit the application:

Figure 8

Trouble Output

Circuit

TB2

Trouble Output Terminal

20 mA/16 V max

Active High

S2 ON

LATCH

LED

CMD-IN

1

2

3

REMOTE

LED

Shaded boxes are factory default settings.

aLatched alarm LED does not affect timing of alarm relay.

bReset the alarm LED by removing and restoring power, or by

toggling the S2 LATCH switch off and on.

cSets function of CMD-IN/Remote LED terminal.

SWITCH OFF ON

LATCH Red alarm LED Red alarm LED

lights for 5 seconds latches ON when

when unit alarms unit alarmsa,b

LED LEDs are disabled LEDs are enabled

except during

power-up test

CMD IN/ TB2 terminal set to TB2 terminal set to

REMOTE Remote LED EnablecCommand Inputc

LED

TESTING

The FG-1025Z should be tested at least once each year. Test

the unit with the FG-701 Glass-Break Simulator. The model FG-

700 Glass-Break Simulator can be used if it is set for the

TEMPered glass sound. Other glass-break simulators will not

give accurate indication of range.

You must place the FG-1025Z in Test Mode before you can test

the unit.

To activate Test Mode:

1. Stand inside the protected zone within 10 feet (3 m) of the

unit.

NOTE: The FG-1025Z will not respond to simulator sounds from

the excluded zone.

2. Switch the FG-701 to ACTIVATE and MANual modes.

3. Point the front of the simulator at the unit and press the red

start button. (See Figure 9.)

You should hear a short buzz from the simulator, and the green

LED on the FG-1025Z should begin flashing about once per

second to indicate it is in Test Mode.

NOTE: In Test Mode the LED disable switch is overridden.

Figure 9

Red Start

Button

Glass-Break

Detector

- 4 -

TESTING (Continued)

Figure 10

Red Start

Button

Glass-Break

Detector

IMPORTANT: Some environmental factors may reduce the sensor

activation range. If you do not see the green LED flashing after pressing

the red start button, move closer to the unit and try again.

If an FG-701 is not available, or if for any reason remote activa-

tion cannot be used, use a screwdriver to short the test pads at

location S3 on the PCB (see Figure 1).This will activate Test

Mode. Make sure to replace the front cover of the FG-1025Z

before beginning test.

To test the FG-1025Z:

1. Place the unit in Test Mode as described above.

2. Set the FG-701 switches to the TEST and FLEX positions.

3. Press the red start button. The simulator will "click" on and

start an eight second armed period.

4. Position the FG-701 near the farthest point of the protected

glass and point it directly at the FG-1025Z.

5. Generate a flex signal by carefully striking the glass with a

cushioned tool. The FG-701 will respond by producing a

burst of glass-break audio. (Refer to Figure 10.)

If both the flex and audio are received properly, the red alarm

LED on the FG-1025Z will light.

IMPORTANT: If window coverings are present, close them fully and hold

the FG-701 behind the window coverings for testing.

NOTE: You can also use the simulator in the MANual mode to test

audio alone. The blinking green LED on the unit will flicker when

the simulator audio is received correctly. (See the FG-701

Operating Instructions for additional information.)

After testing, exit the Test Mode using the same procedure for

activating the Test Mode. The FG-1025Z also will automatically

exit Test Mode after ten minutes. If the red alarm LED is lit, it will

automatically extinguish upon exiting Test Mode.

LED Indicators (Continued):

Condition Green LED Red LED

Normal, no event OFF OFF

Normal, event detected Flicker OFF

Normal, break detected OFF ON

Power-up self-test ON, one second ON, one second

Trouble detected Flash ON/OFF Flash OFF/ON

Test mode, no alarm Flash once per second OFF

Test mode, event detected Flicker OFF

Test mode, alarm Flash once per second ON

LED Indicators:

The two LED's on the front cover are used to indicate the

sensor's operational status. The following table summarizes the

LED operation when the LED's are enabled.

APPLICATIONS INFORMATION

The FG-1025Z is designed to detect framed glass broken by an

impact sufficient to make a hole.

To minimize the chance of false alarms:

•Do not use outside.

•Avoid installing in rooms with high-level noise sources, such

as air compressors, bells, power tools, etc., if those sources

can be active when the detector can signal an alarm.

•Test false alarm immunity by activating any known noise

sources in the room.

To maximize detection:

•Mount the unit on a wall or ceiling directly opposite the glass

if possible. The least desirable mounting location is on the

same wall as the glass.

•Minimize range to the glass. Do not install beyond the

maximum specified range even if testing indicates greater

range.

•Verify all installations back to the panel to be sure that the

protection loop is intact.

Self-Test Chart

Power-Up Self-Tests

• RAM Test

Write & read all RAM locations

with one's & zero's

• Arithmetic Test

Verify correct results for CPU

arithmetic

• Logic Test

Verify correct results for data

comparisons

• Clock Rate Test

Check clock frequency by

measuring external time

constants

• Active Analog Circuit Test

Inject signals into analog

channels to check gains,

filters, A/D, and interrupts

Continuous Self-Tests

• Watchdog

Supervises microcontroller

• ROM Checksum

Firmware ROM checksum

verified

• RAM Test

Write & read RAM locations

with one's & zero's

• Logic Test

Verify correct results for data

comparisons

• Passive Analog Circuit Test

Verify analog inputs are within

normal bounds

SELF-TESTS

The FG-1025Z automatically performs a series of self-tests

during power-up, and continuously (when the sensor is not

detecting a trouble or alarm condition.) Refer to the chart below

for descriptions of the self-tests performed:

- 5 -

SPECIFICATIONS

Range:

25' (7.6 m) maximum

No minimum range

Operating Temperature:

32oto 120oF (0oto 49oC)

Storage: -4oto 122oF

(-20oto 50oC)

Alarm Duration:

5 seconds (unaffected by

alarm LED latching)

Alarm Relay:

Form C

125 mA maximum

25 VDC maximum

Tamper Switch:

Combination cover and

wall tamper

25 mA maximum

24 VDC maximum

Power Requirements:

8 - 14 VDC; 25 mA typical at

12 VDC, 35 mA max

AC Ripple: 4 Volts peak to peak

at Nominal 12 VDC

RF Immunity:

30 V/m, 10 MHz - 1000 MHz

ESD Immunity:

10 kV;

Discharges of either polarity to

exposed surfaces

Thickness

Type Minimum Maximum

Plate 3/32" (2.4 mm) 1/4" (6.4 mm)

Tempered 1/8" (3.2 mm) 1/4" (6.4 mm)

Laminated11/8" (3.2 mm) 9/16" (14.3 mm)

Wired 1/4" (6.4 mm) 1/4" (6.4 mm)

Coated21/8" (3.2 mm) 1/4" (6.4 mm)

Sealed Insulating11/8" (3.2 mm) 1/4" (6.4 mm)

1Laminated and sealed insulating glass types are protected only if both plates of the unit are

broken.

Protected Glass:

Minimum size for all types is 11"

(28 cm) square; Glass must be

framed in the wall of the room or

mounted in a barrier of 36" (0.9 m)

minimum width.

Dimensions:

4.25" OD x 0.88" THK

(108 mm x 22.4 mm)

Weight:

4.5 oz., (128 g)

Packaged Product: 7.5 oz, (213 g)

Command Input/

Remote LED Enable:

Active low (0 - 1.5 V)

High impedance for inputs less

than 5.6 V. Draws less than 1 mA

for inputs up to 16 V.

2For glass coated on the inner surface with 3M scotchshield type RE35NEARL or Hard Glass

Security Film, reduce maximum range to 15 feet (4.6 m).

Patents:

U.S. and International Patents

Applied For

Approvals/Listings:

Accessories:

FG-701 Glass-Break Simulator

FG-SP2 Spacer Plate

Trouble Output:

Open collector, active high; 1K

series resistor; 20 mA/16 V max

Note: The FG-1025Z Glass-Break Detector is designed for primary

perimeter security. For a complete security system, additional

interior protection devices are recommended.

FCC Notice: This equipment has been tested and found to comply with

the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harm-

fulinterference in aresidential installation. This equipmentgenerates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures: 1) Reorient or

relocate the receiving antenna, 2) Increase the separation between the

equipment and receiver, 3) Connect the equipment into an outlet on a cir-

cuit different from that to which the receiver is connected. The installer can

also consult an experienced radio/television technician for additional sug-

gestions, if necessary.

In addition, a booklet on interference, prepared by the Federal Communi-

cations Commission, is also available for reference. Order "Interference

Handbook" from the U.S. Government Printing Office, Washington D.C.

20402, stock no. 0004-000-00450-7.

SELF-TESTS (Continued)

If any self-test fails, the unit will signal trouble by flashing the LED's

alternately about once per second. Protection will continue if pos-

sible. If the trouble condition clears, the LED's will return to the

normal state. Always return the unit for repair if there is any indica-

tion of trouble, even if the trouble is temporary.

TECHNICAL INFORMATION

The FG-1025Z is a directional glass-break detector. It has

precisely-defined protected and excluded zones. There is no

reduction in sensitivity at the edges of the protected zone, and

the device completely rejects sounds in the excluded zone, no

matter how loud they are, or how similar to glass-break they are.

This performance is achieved through the use of two micro-

phones and time-of-arrival (TOA) processing. When a sound is

generated in the room the microphone nearest the sound will

receive it first. The microcontroller in the unit monitors all sound

events received by the microphones and processes only those

received first at the "front" microphone, which is pointed toward

the protected zone. Sounds arriving at the "back" microphone

first are simply ignored.

Because of the symmetry of the unit, the space surrounding the

front and back microphones is divided evenly between protected

and excluded zones. A region 20 degrees wide on each side of

the unit is the keep-out zone. In this region sound may or may

not be processed. Glass to be protected should never be within

the keep-out zone. However, false alarm immunity is at least as

good in the keepout zones as it is in the protected zone.

- 6 -

Copyright 1994 C&K Systems, Inc.

All Rights Reserved

5-051-333-00 Rev A

U.S. and International Patents Applied For.

C&K is a registered trademark of C&K Components, Inc.

LIMITED WARRANTY

SYSTEMS, Inc.

Seller warrants its products to be in conformance with its own plans and specifications and to be

free from defects in materials and workmanship under normal use and service for 18 months from

the date stamp control on the product or for products not having a C&K Systems date stamp, for

12monthsfromthe dateof originalpurchase, unlessthe installationinstructions orcatalogue sets

forth a shorter period, in which case the shorter period shall apply. Seller's obligation shall be

limited to repairing or replacing, at its option, free of charge for materials or labor, any part which

is proved not in compliance with Seller's specifications or proves defective in materials or

workmanship under normal use and service. This warranty is void if the product is altered or

improperly repaired or serviced by anyone other than C&K Systems factory service. For warranty

service, contact your local C&K Service Center.

THEREARENOWARRANTIES,EXPRESSORIMPLIED,OFMERCHANTABILITYORFITNESS

FORA PARTICULARPURPOSEOR OTHERWISE,WHICHEXTEND BEYONDTHEDESCRIP-

TION ON THE FACE HEREOF. In no case shall Seller be liable to anyone for any consequential

or incidental damages for breach of this or any other warranty, express or implied, or upon any

otherbasisof liabilitywhatsoever,even iftheloss ordamageiscaused bySeller'sown negligence

or fault.

Seller does not represent that its product may not be compromised or circumvented; that the

product will prevent any personal injury or property loss by burglary, robbery, fire or otherwise; or

that the product will in all cases provide adequate warning or protection. Buyer understands that

a properly installed and maintained alarm may only reduce the risk of burglary, robbery, or fire

without warning, but it is not insurance or a guarantee that such will not occur or that there will be

no personal injury or property loss as a result. CONSEQUENTLY, SELLER SHALL HAVE NO

LIABILITY FOR ANY PERSONAL INJURY, PROPERTY DAMAGE, OR OTHER LOSS BASED

ON A CLAIM THAT THE PRODUCT FAILED TO GIVE WARNING. However, if Seller be held

liable, whether directly or indirectly, for any loss or damage arising under this Limited Warranty or

otherwise, regardless of cause or origin, Seller's maximum liability shall not in any case exceed

thepurchasepriceoftheproduct,which shallbe fixedas liquidateddamages andnot asa penalty,

and shall be the complete and exclusive remedy against Seller.

Thiswarranty replacesall previouswarranties andis the onlywarranty madeby C&KSystems on

this product. No increase or alteration, written or verbal, of the obligation of this warranty is

authorized.

Table of contents

Other C & K Systems Security Sensor manuals

Popular Security Sensor manuals by other brands

Honeywell

Honeywell FlexGuard 5853 installation instructions

MDT Technologies

MDT Technologies SCN-P360D3.01 Technical manual

ADEC Technologies

ADEC Technologies TDC3 F-F-31 Series Quick reference guide

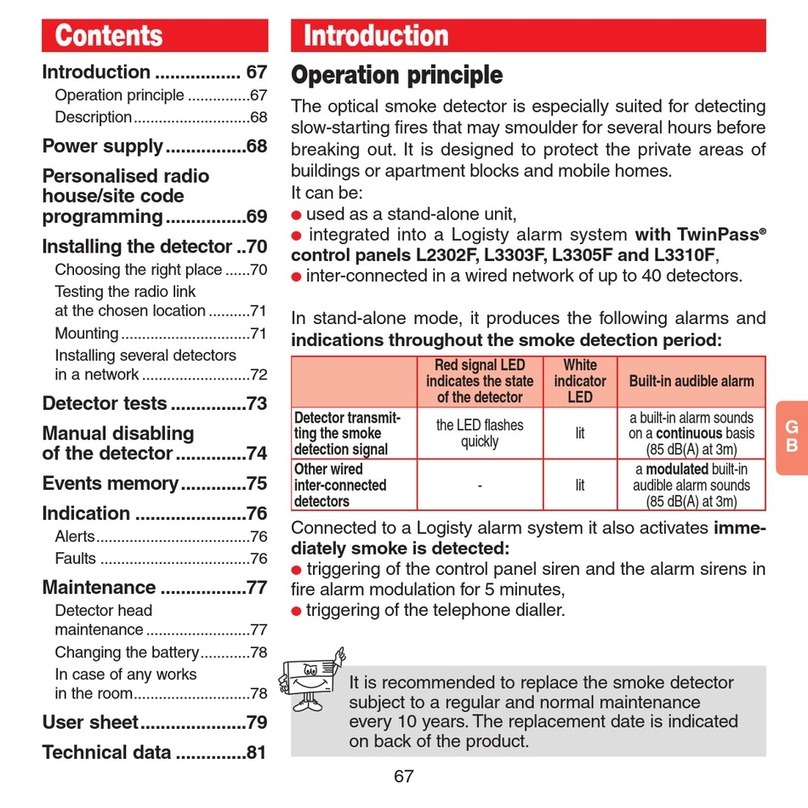

LOGISTY

LOGISTY L3156X instructions

Farnell

Farnell 881 Series Installation and operation

MyTana

MyTana RL8800 user manual