Carefully read the instruction manual.

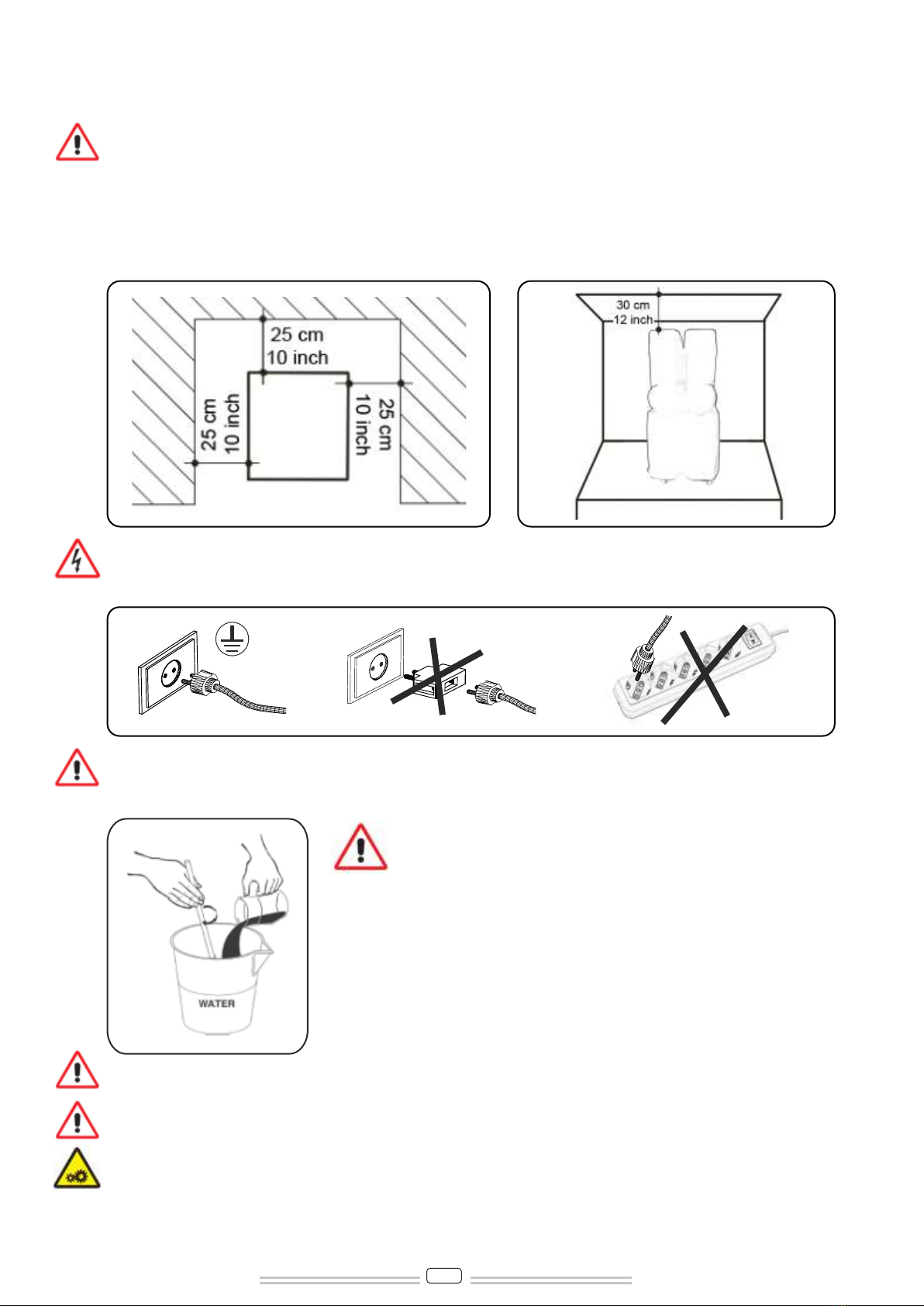

The mains connection must comply with the safety regulations in force in the country of use.

The socket must be in conformity with the type of plug installed on the same and its size shall comply with the

data of the serial number plate.

The machine must be connected to a grounding system in accordance norms in force and connected to a

system with differential magnetothermal switch.

The power cord must be protected from contact with liquids, should not be crushed, it must not be wound in a

coil when the machine is in operation, must not be tampered with.

If the power cord is damaged, it must be replaced by the Manufacturer or by the technical assistance

service or in any case a person with similar qualification, so as to prevent any risk.

Do not leave the lights on when the device cannot be supervised.

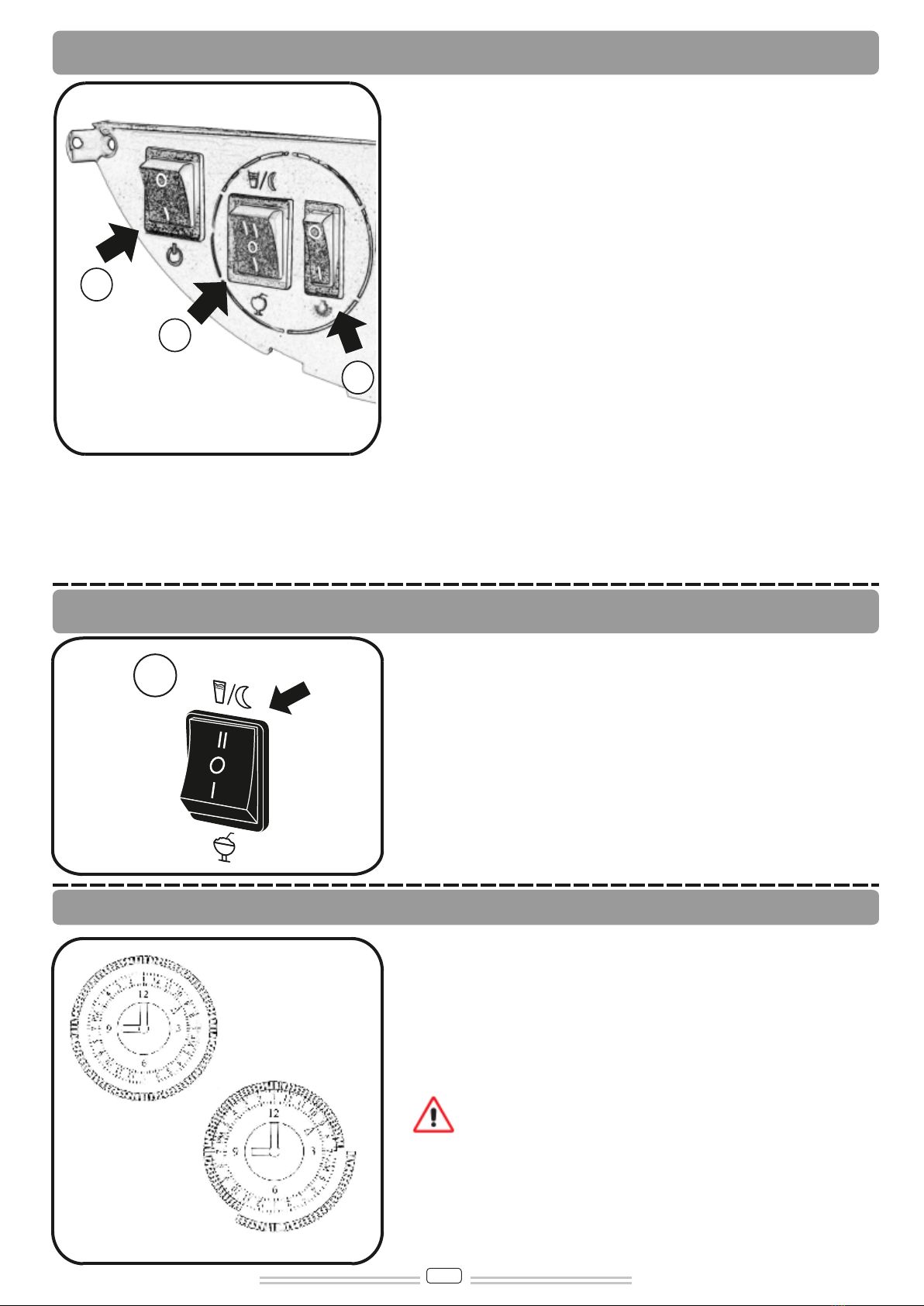

In any emergency situation, to stop the machine, firmly press the main switch to -0 -.

In case of freezing shut down the machine and contact the service centre or a qualified technician.

In case of fire, immediately clear the area to allow trained personnel equipped with suitable protective

equipment to intervene. Always use approved fire extinguishers, never use water or unknown substances

It is prohibited to:

install the machine in different ways than those described in this manual.

install the machine in areas where a jet of water can be used.

use the machine in the vicinity of inflammable and/or explosive substances.

use spare parts which are not recommended by the manufacturer. All repairs can be performed only by a

specialist and trained personnel.

make any technical changes to the machine.

wash the machine with a water jet.

utilise the machine in different ways than those described in this manual.

use the machine in altered psychophysical conditions.

Install the machine in the vicinity of machines that can be a source of heat to other appliances.

use of the machine in an environment of fire risk;

use of the machine for dispensing substances not suited to the characteristics of the same.

use of the machine in an environment with a low or insufficient volume of air ventilation.

obstruct the grilles positioned to the side of the machine, either with fixed elements or with mobile elements

(such as glasses and other accessories).

installation of the machinery in external environments or outdoors.

The machine must be periodically checked by a qualified technician, at least once a year.

This periodic inspection is necessary to maintain a high level of safety of all the installed components and of

the machine itself.

In case of a worn component, this must be replaced with a new original part. Do not use the machine if even a

single component is worn or defective.

INSTALLATION

2