TABLE OF CONTENTS

1. GENERAL INFORMATION ....................................................................................... 4

1.1 INFORMATION ABOUT THE MANUFACTURER ................................................. 4

1.2 BRANDING ....................................................................................................... 4

1.3 CE DECLARATION OF CONFORMITY ................................................................. 5

1.5 SECURITY PROCEDURES ................................................................................... 6

1.5.1 WARNINGS FOR OPERATOR SAFETY ............................................................. 6

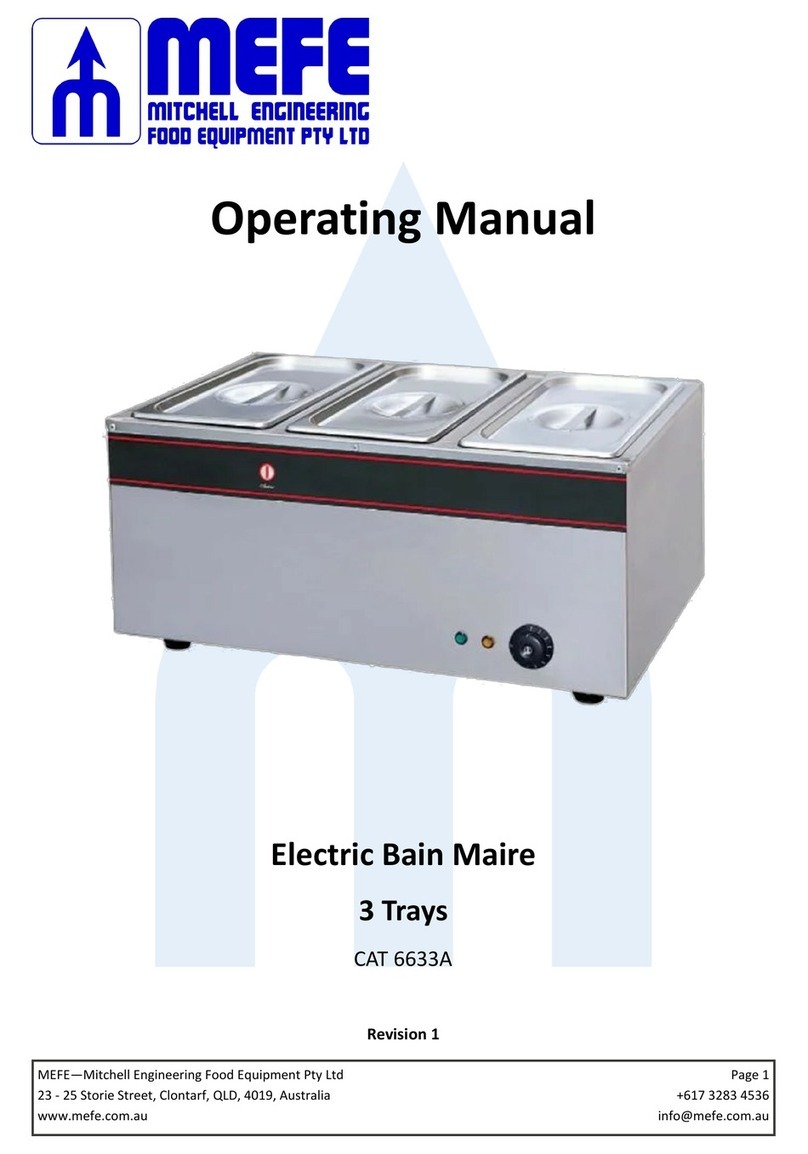

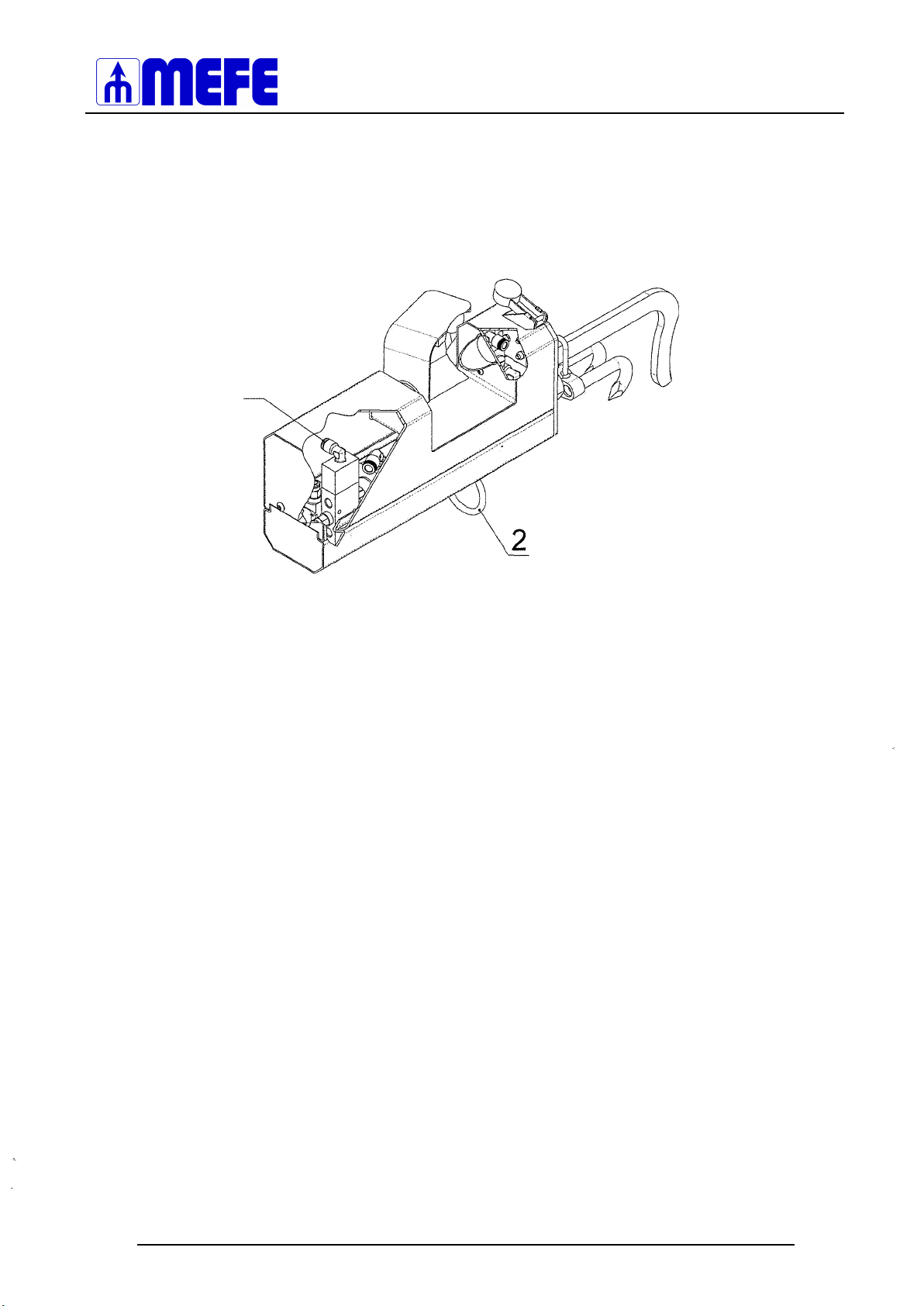

2. GENERAL DESCRIPTION ......................................................................................... 7

3. HOW TO USE THE MANUAL ................................................................................... 8

4. TECHNICAL DATA .................................................................................................. 10

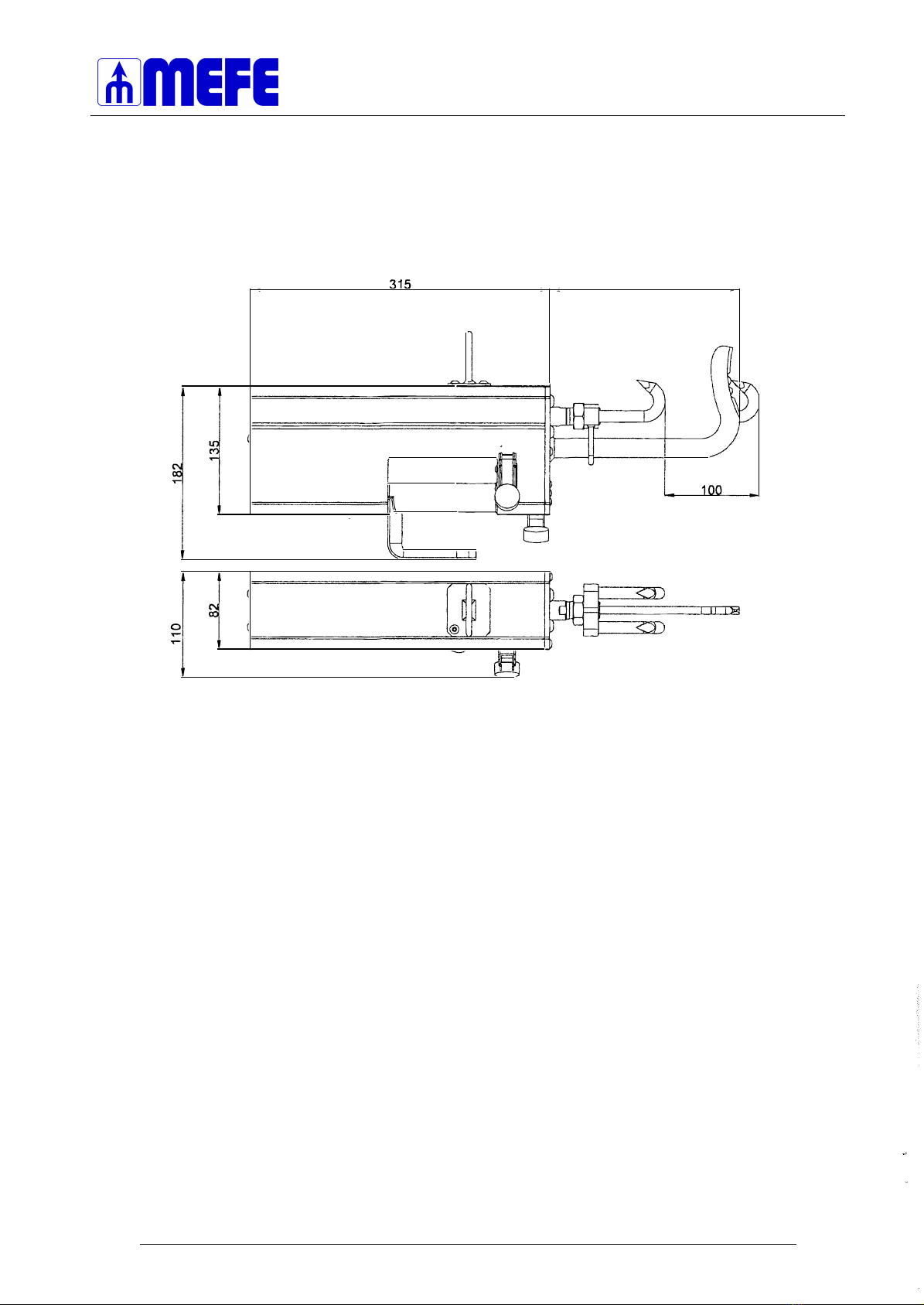

4.1 MAIN DIMENSIONS ......................................................................................... 10

4.2 CHARACTERISTIC DATA ...................... : .......................................................... 10

5. INSTALLATION ....................................................................................................... 11

6. CLEANING ............................................................................................................. 12

7. DEMOLITION AND DISPOSAL ................................................................................ 12

8. FUNCTION AND USE .............................................................................................. 12

8. 1 EXPECTED USE ................................................................................................. 12

8.2 UNEXPECTED USE ............................................................................................ 12

8.3 SIGNALS ........................................................................................................... 13

8.4 SAFETY REGULATIONS ..................................................................................... 14

8.5 RESIDUAL RISKS ............................................................................................... 15

8.6 INDIVIDUAL PROTECION DEVICE ..................................................................... 15

9. USE ........................................................................................................................ 16

10. MAINTENANCE ...................................................................................................... 17

11. SPARE PARTS ......................................................................................................... 17