8 ARTEMIS Digital Broadcast Production Console Information

IMPORTANT INFORMATION

After Sales Modifications

Please be aware that any modifications

other than those made or approved by

Calrec Audio Limited or their agents, may

invalidate the console’s warranty. This

includes changes to cabling provided by

Calrec and variations to the recommended

installation as detailed in Calrec

documentation.

Modifications to this equipment by any

party other than Calrec Audio Limited

may invalidate EMC and safety features

designed into this equipment. Calrec

Audio Limited can not be liable for any

legal proceedings or problems that may

arise relating to such modifications.

If in doubt, please contact Calrec Audio

Limited for guidance prior to commencing

any modification work.

Installation

In many installations the AC power

connectors will not be readily accessible,

effectively making the equipment

permanently connected. The installation

should be carried out in accordance

with all applicable installation rules and

regulations.

Service Personnel

The AC power disconnect devices are

the 2 x IEC (IEC60320-1 C13/C14)

couplers located at the rear of each unit.

WARNING: The apparatus has a dual

power system. It is essential that BOTH

AC power IEC couplers are disconnected

to prevent exposure to hazardous voltage

within the unit.

Third Party Equipment

Integrating third party equipment into

a Calrec system may compromise the

product’s ability to comply with the

radiated emission limits set in the latest

EMC (Electro Magnetic Compatibility)

standard.

Calrec Audio Limited can not be

responsible for any non-conformities

due to use of third party equipment. If

in doubt, please contact Calrec Audio

Limited for guidance prior to integrating

any third party equipment.

ESD (Static) Handling Procedures

In its completed form, this equipment has

been designed to have a high level of

immunity to static discharges. However,

when handling individual boards and

modules, many highly static sensitive

parts are exposed. In order to protect

these devices from damage and to protect

your warranty, please observe static

handling procedures, for example, use an

appropriately grounded anti-static wrist

band. Calrec will supply an electrostatic

cord and wrist strap with all of its digital

products.

All modules and cards should be returned

to Calrec Audio Limited in anti-static

wrapping. Calrec Audio Limited can

supply these items upon request, should

you require assistance.

This applies particularly to digital products

due to the types of devices and very

small geometries used in their fabrication,

analogue parts can however still be

affected.

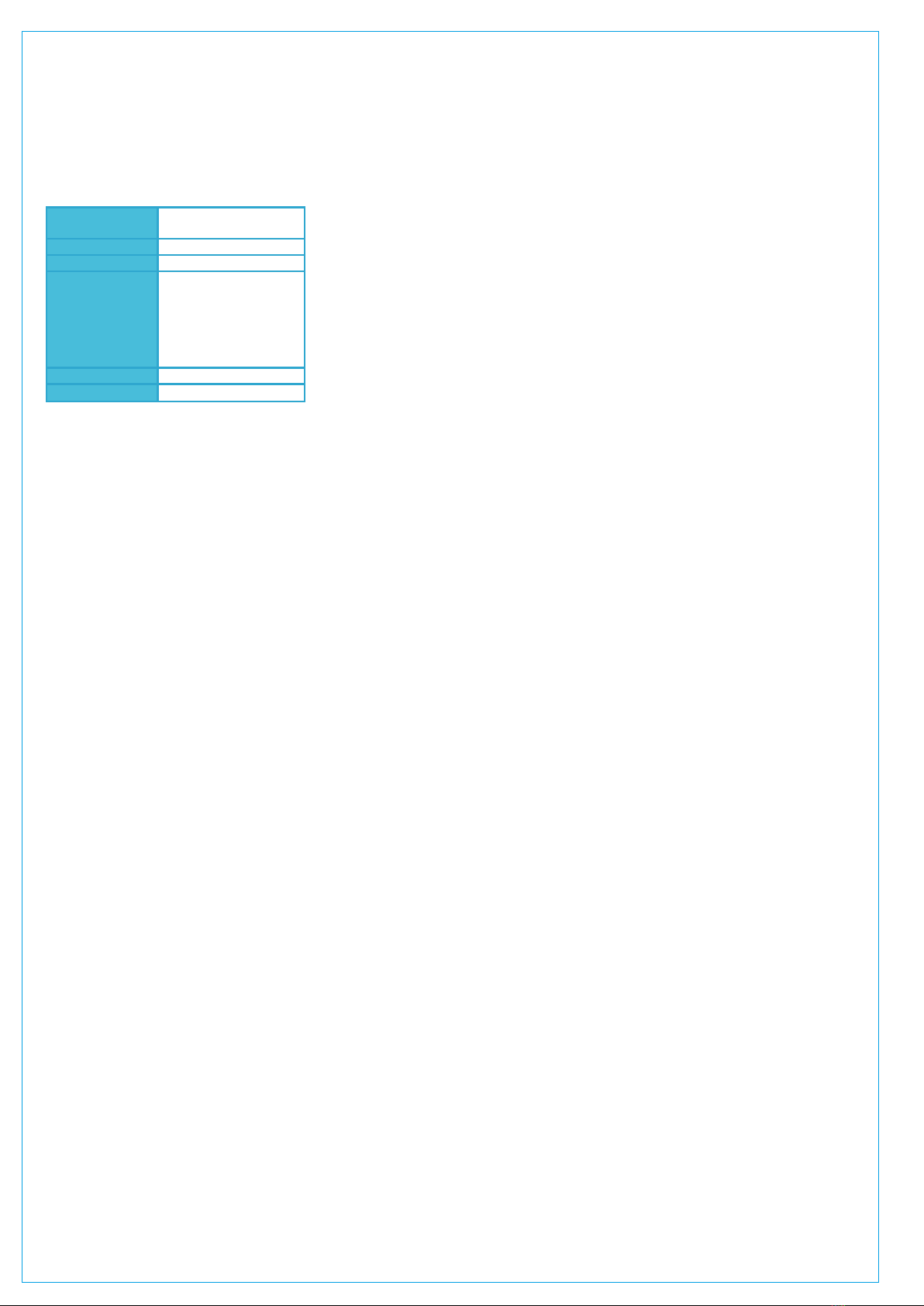

RoHS Legislation

In order to comply with European RoHS

(Reduction of Hazardous Substances)

legislation, Calrec PCB and cable

assemblies are produced with lead-free

(tin/copper/silver) solder instead of tin/

lead solder. See Fig 1.

In the unlikely event of a customer

having to carry out any re-soldering on

Apollo, Artemis or Hydra2 hardware,

it is imperative that lead-free solder is

used; contaminating lead-free solder with

leaded solder is likely to have an adverse

effect on the long-term reliability of the

product.

Circuit boards assembled with lead-free

solder can be identified (in accordance

with IPC/JEDEC standards) by a small

oval logo (see Fig 2) on the top-side of

the circuit board near the PCB reference

number (8xx-xxx). The same logo is used

on the connector hoods of soldered cable

assemblies.

If in doubt, please check with a Calrec

customer support engineer before

carrying out any form of re-soldering.

ISO 9001 and RAB Registered

Calrec Audio Ltd has been issued

the ISO9001: 2008 standard by the

Governing Board of ISOQAR.

The award, for both UKAS (Fig 3)

and RAB (Fig 4) registration, is the

most comprehensive of the ISO9000

international standards. Granted in

recognition of excellence across design,

development, manufacture and after-

sales support, the certification follows a

rigorous and thorough review of Calrec’s

internal and external communication and

business procedures.

FIG 1 - LEAD FREE

Pb

Pb-Free

Lead

Free

FIG 2 - LEAD FREE STICKER

e1

FIG 3 - UKAS REGISTRATION

FIG 4 - RAB REGISTRATION