3.4. Re-fuelling

The appliance must function door closed and top

plate correctly set up.

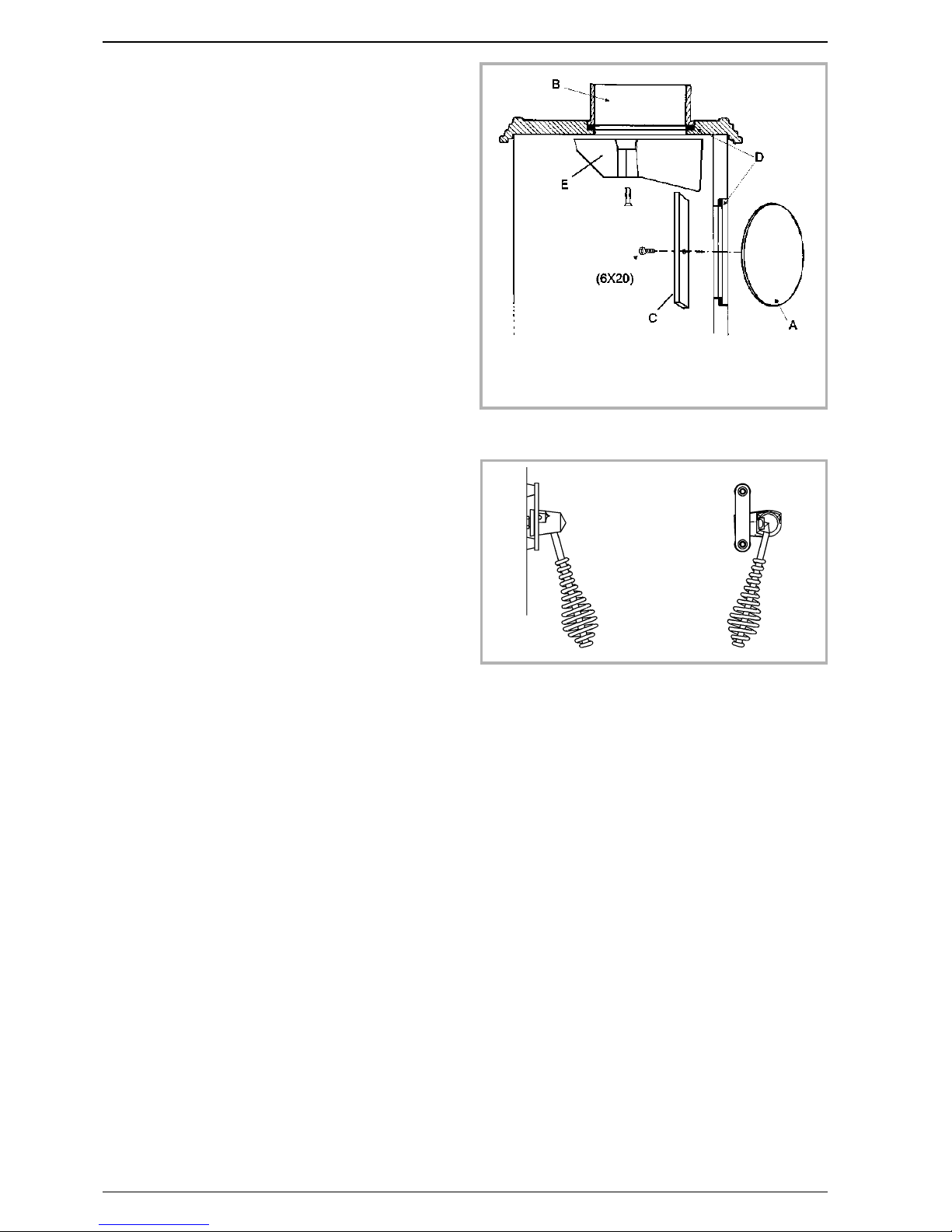

The burning rate can be adjusted by the air control flap

(# B Fig. 7). Experience will show you which settings

are best for your situation. The lighting flap must be

closed (# C2 Fig. 7)

-The airwash system works with the top airslide. When

the top airslide is full open the system works at its

strongest efficiency.

-The more closed down the airslide is, the less effective

the airwash will be ( when shut down completely, the

airwash system can not function )

Loading the fuel :

-It is advisable to wait for the fire to be reduced to hot

embers before re-loading. The door should also be

opened slowly when re-loading.

-The minimum reloading interval for nominal heat

output is 1.5 hours.

-For a briskly burning fire, there should always be at

least two logs in the fire. The fire will burn better if

there are several logs.

-For a slower burning fire (for example, at night), select

larger logs.

-Close the loading door.

Open the lighting flap for a while (# C1 Fig. 7).

3.5. Instructions for use with solid fuel

3.6. lighting

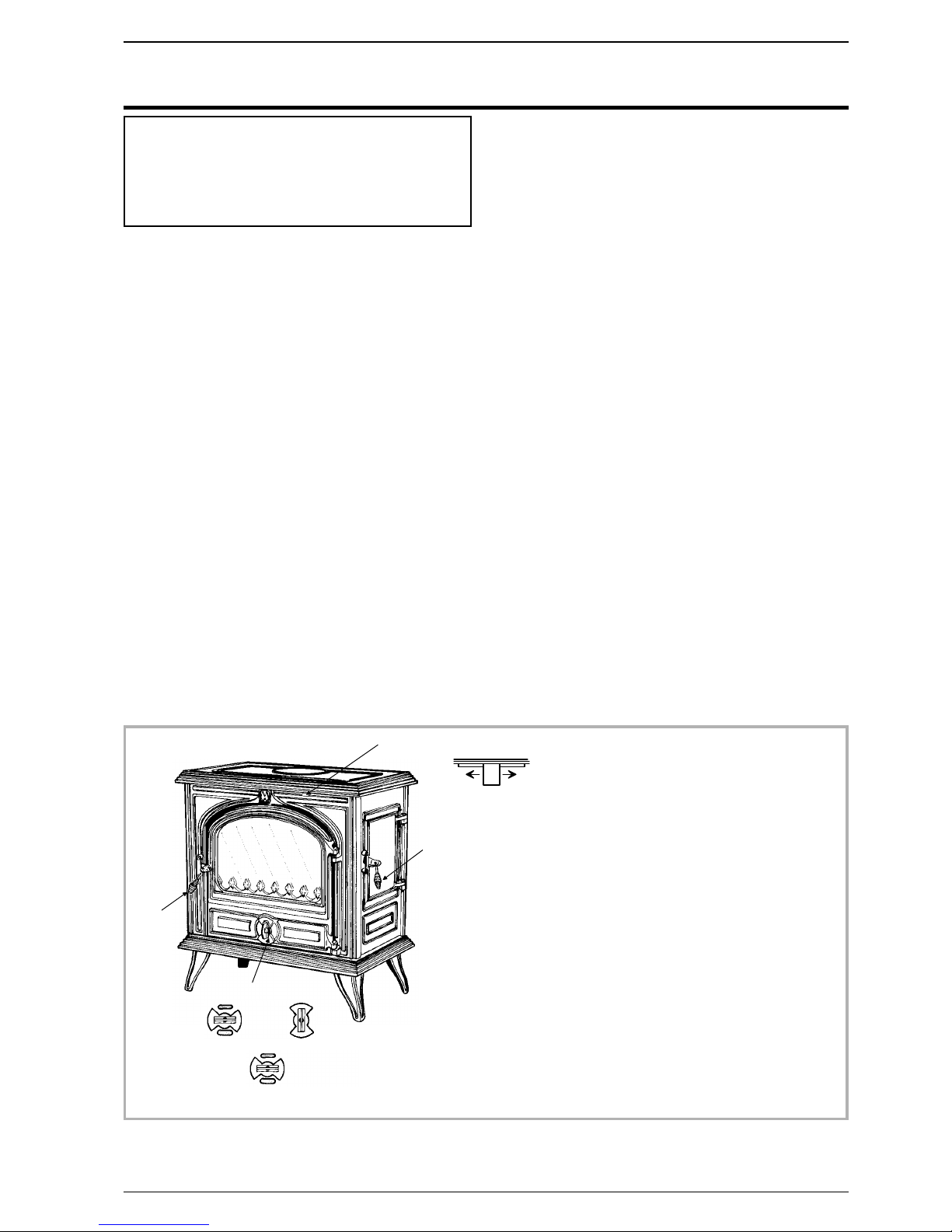

-Slide the top air control (# B1) to the right. Open the

lower spin wheel.

-Lay firelighters or rolled up newspapers on the grate

with a reasonable quantity, if necessary, of dry kindling

wood. Place a small quantity of solid fuel on top.

-Light the newspaper or firelighters using a long taper

and close the door.

-When the fire is burning fiercely, add further fuel.

-When the stove body is hot, close the top air control by

sliding to the left.

-The burning rate can now be adjusted by rotating the

lower spin wheel.

3.7. Re-fuelling

-Open the lower spin wheel.

-Open the glass door and add fuel.

-Leave the lower spin wheel open for a few minutes to

allow the initial volatiles in the fuel to burn.

-Adjust the lower spin wheel to the desired position.

3.8. De-ashing

-Remove ash until glowing ashes start falling into the

pan. (# C3, fig. 7, p. 7)

-Ashes must be removed before loading the firebox

and when the fire doesn’t burn efficiently.

-Ashes must never be allowed to pile up to the grate.

The grate would not be cool down and could rapidly be

damaged.

-Empty the ashes when the appliance is cold,

-Empty the ashes carefully with regard to the live

embers.

REMEMBER TO BURN SOLID FUEL CORRECTLY,

AlR SHOULD BE ALLOWED TO FLOW FROM THE

ASH PIT AREA THROUGH THE GRATE AND

THROUGH THE FUEL. IF THE GRATE OR ASH PAN

ARE CONGESTED, THE PERFOMANCE WILL BE

EFFECTED.

If burning solid fuel, always empty the ash pan at least

once a day or whenever it is full of ashes. Never allow

the ashpan to overfill allowing ash to be in contact with

the underside of the grate. If this condition is allowed,

the grate will wear out pre-maturely.

3.9. Maintenance of the stove

•The appliance must be cleaned regularly , together

with the connecting pipe and the flue pipe.

•Remove all deposits from the combustion chamber

and clean the grate area.

•Cleaning of the glass door can be done with a soft cloth

dampened with water and vinegar or potassium ; this

must be done when the appliance is cold ; then rinse

with clear water. Do not use abrasive cleaners.

•The “vitroceramic” glass will resists to temperatures of

up to 750 C. Should the glass break due to misuse, it

must be replaced by the manufacturers own product.

•All the casing parts can be cleaned using a soft cloth

either dry, or slightly damp. In case of condensation or

water splashes clean the parts before they dry out.

•Check that there are no obstructions before relighting

after a long period of disuse.

•The appliance must not be used with a flue serving

several appliances.

•To maintain the grates ventilation free of any

obstruction.

Warning : The appearance of cracks when burning the

enamelled units is quite usual and tends to disappear

when the appliance is cooling down. It should not be

considered as a defect but rather as a patina of the

enamel which does not affect its quality nor its service

ability.

3.10. Maintenance of the Chimney

Very important : In order to avoid any incident

(chimney fire, etc...), maintenance tasks must be

carried out regularly. If the appliance is regularly used,

the chimney should be swept several times per year,

together with the stovepipe connection section.

If the chimney catches fire, you must cut off the flue

draught, close the doors and windows, hatches and

keys, remove the embers from the stove, stop up

the connection hole with wet cloths and call the Fire

Brigade.

DO NOT OPEN THE DOOR OF THE APPLIANCE

(OR AIR INLET) UNDER ANY CIRCUMSTANCES

Chimney condition should be checked at least once per

year by a professional engineer.

8Technical manual “1141”

Camargue - ref. 134 10 15 Instructions for user