3

Model 580A Differential Pressure Switch Section 1

Section 1—Introduction

General

The 580A Differential Pressure Switch actuates single or dual signal circuits

when predetermined limits of ow or level are exceeded. The DPU is con-

nected to the process or vessel by tubing or piping. Changes in differential

pressure (DP) at the DPU produce a mechanical output which moves a pointer

and switch actuation controls.

For ow measurements, the instrument is connected to the high-pressure

and low-pressure sides of a primary device in the process run. Normally the

primary device will be an orice plate, venturi, or ow tube.

For liquid level measurement applications, the instrument is connected to

measure changes in differential pressure caused by variations in hydrostatic

pressures of the liquid in a tank.

The 580A switch is available in three model variations:

• Indicating Switch (Model 580A-0). This model, shown on the manual

cover, has a thick tempered plate glass lens and provides a visual indica-

tion of the difference in the two monitored pressures.

• Blind Switch (Model 580A-2).This model has a solid metal cover and

provides no visual indication of differential pressure.

• Blind Switch with Internal Indicator. Unlike the indicating model with

the glass lens, there is no externally visible indicator. However, internally,

components are the same as in Model 580A-0. With the cover removed, a

user can use the internal indicator to determine DPU input pressure when

making adjustments to the switch setpoints.

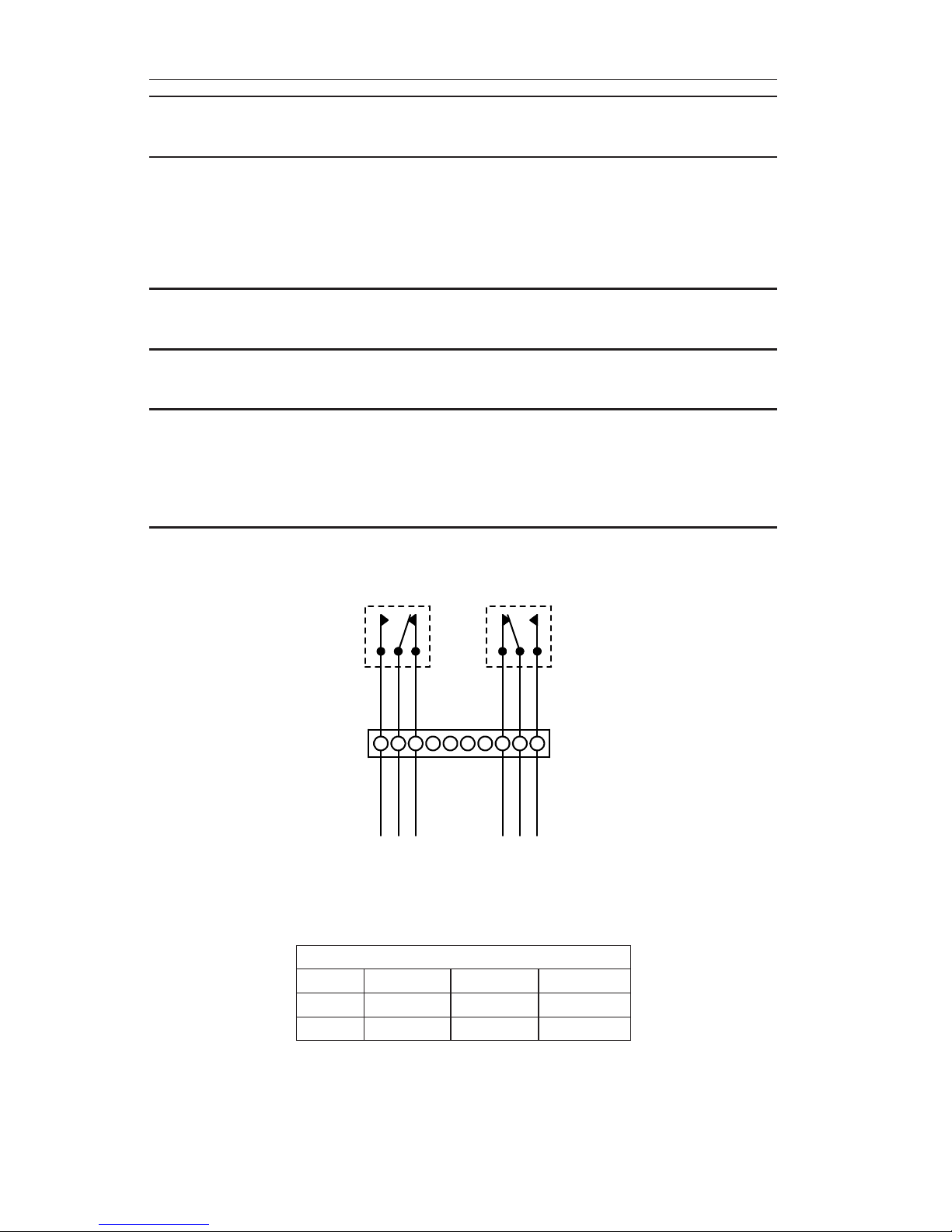

The Model 580A uses two independently adjustable single-pole double-throw

(SPDT) snap-acting switches that are rated for high temperatures. Both sides

of the switches are wired, enabling the switches to serve both normally-open

and normally-closed applications. The direct-set switch contacts are adjustable

over a scale range of 10-90% nominal. Switches and all adjustments are read-

ily accessible when the cover is removed (see Figures 1.1 and 1.2, page 4).

The 580A Switches (indicating and blind) are qualied per IEEE 323-1974,

IEEE 344-1975, IEEE 381-1977and NUREG 0588, Rev. 1 for either Func-

tional and/or Pressure Boundary Integrity service in limited harsh environ-

ment applications.

The switch case is drawn stainless steel with a sealed glass header for the

electrical interface with the switches. No additional conduit seals are required

to ensure the integrity of the instrument.