EN

Series DRCS drive for stepper motors

10

PROG. TYP

COMMAND FORCE [N]

max 54 POSITION [mm]

max 1500 VELOCITY [mm/s]

max 3333 ACC [mm/s2]

max 5000 DEC [mm/s2]

max 5000

1 pos. Absolute 0.000 100.000 500.000 100.000 100.000

CPU 2.0 GHz or higher

RAM 2 GB or higher

HD space 600 MB or higher

Communication port USB 2.0

Operative system Windows 7, Windows 8

Screen resolution 1280x720

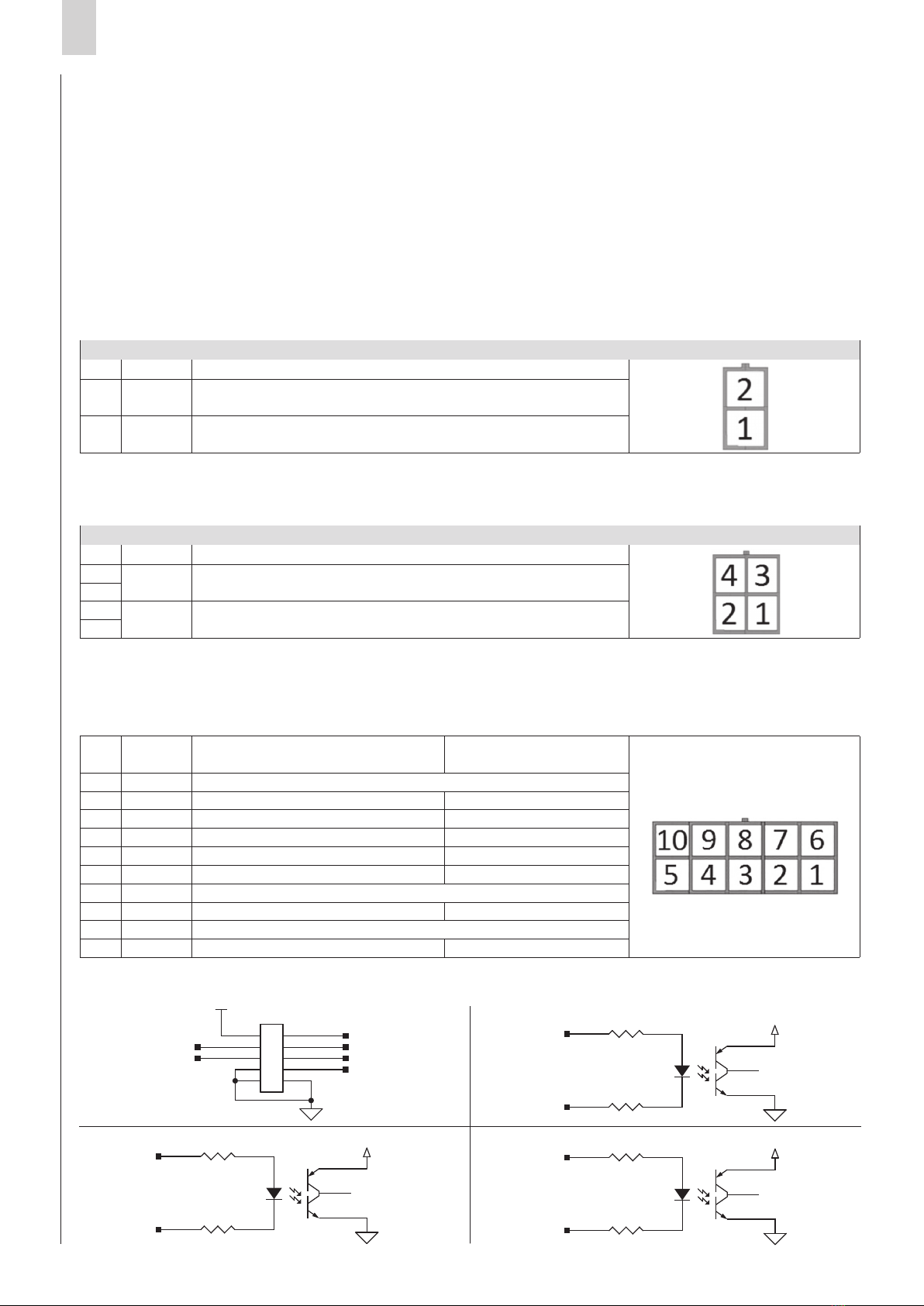

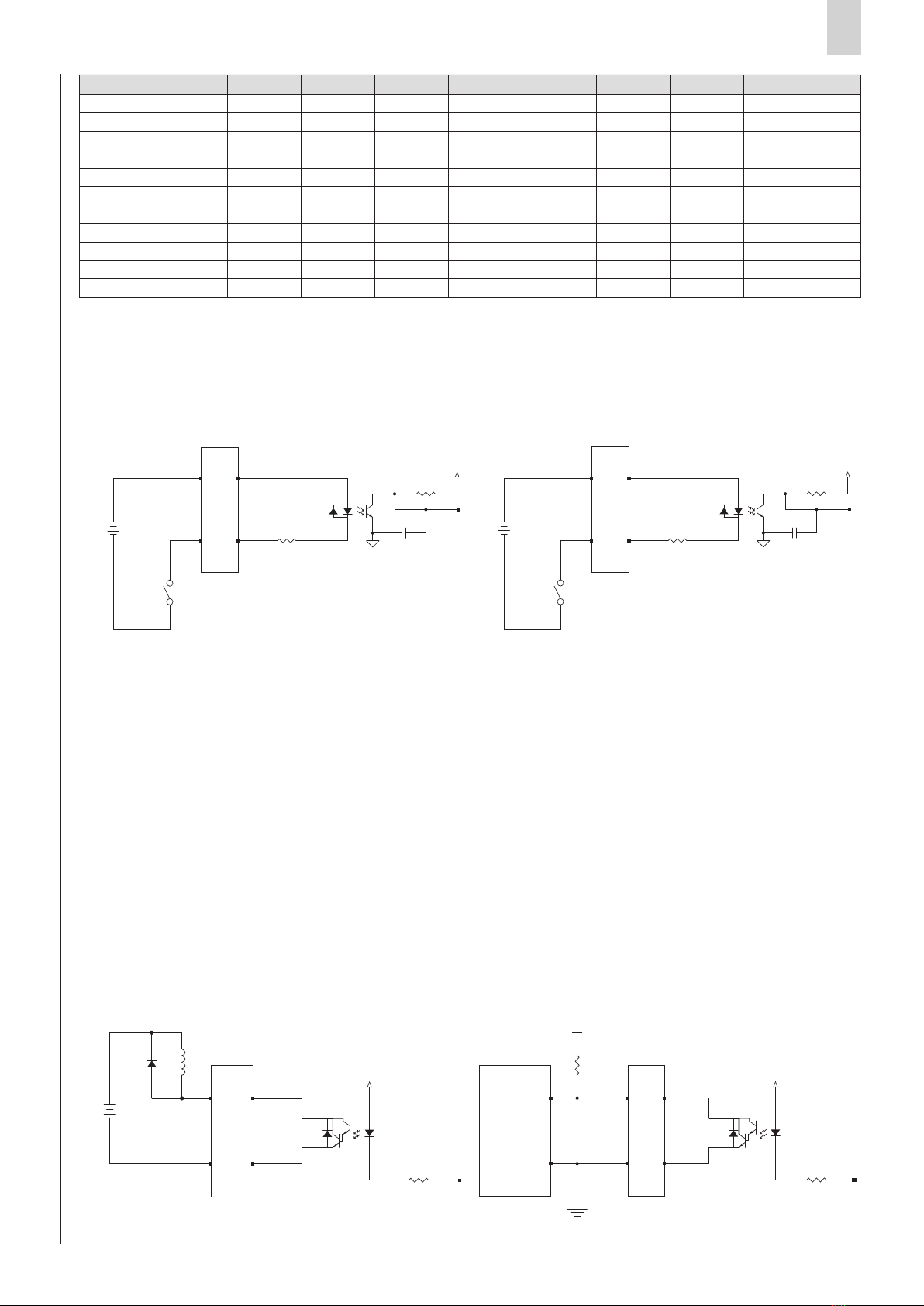

The available outputs are:

- Ready (RDY): indica che l’azionamento DRCS è abilitato senza allarmi, ed è pronto a ricevere un comando di moto.

- Homing OK (HOK): indica che la procedura di Homing (ricerca della posizione dio zero) è stata completata correttamente.

- Motore in posizione (POS): indica che il movimento è stato eseguito correttamente e la posizione è stata raggiunta.

- Busy (BSY): indica che il motore si sta muovendo e non può ricevere un ulteriore comando.

- Allarme (ALM): indica uno stato di allarme; nella tabella di allarme sono riportate tutte le possibili cause di guasto.

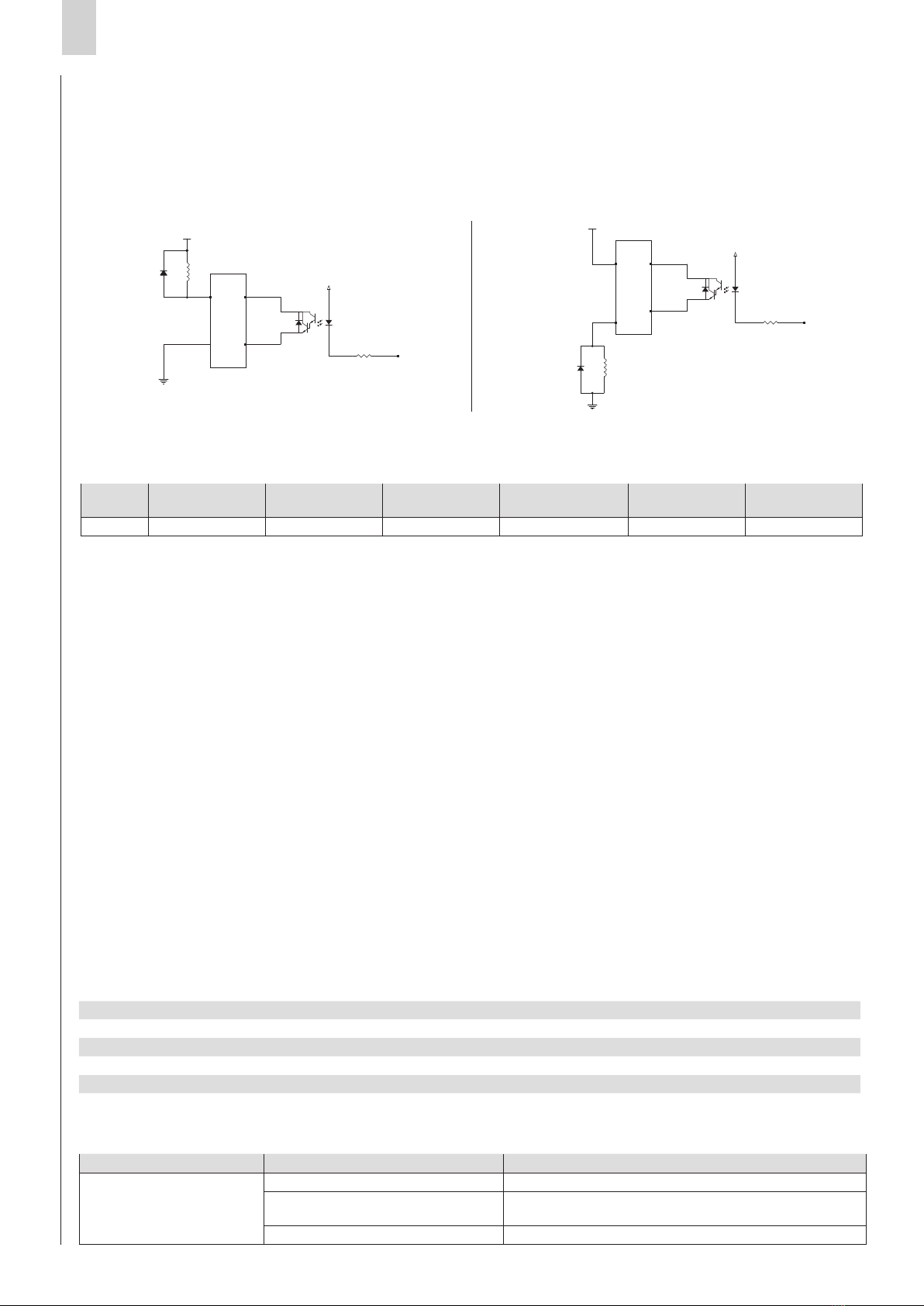

- Configurable output (OUT+ and OUT-): it is possible to set this output via the QSet software (for more details

on using the configurator, specifically this feature, refer to the manual) as either PNP or NPN type, as shown below.

7.10 Steps to realise a movement

• In QSet, configure one or more command lines and load them to the DRCS drive using the “PC to Drive” command.

Example: position 100 mm, velocity 500 mm/s, acceleration and deceleration 100 mm/s2 entered into row 1:

- Enable the DRCS drive by setting the Enable input (ENB).

- Deactivate all digital inputs (from IN0 to IN6) and verify, by observing the Ready output (RDY), that the DRCS drive is

ready. If yes, generate a pulse (minimum width of 2ms) on the Strobe input (STB); the Homing procedure then starts and

the Busy output (BSY) becomes active until the motion has ended.

- When the Homing procedure ends (refer to the Homing OK output (HOK), change the IN0 state to 1 and hold the inputs

IN1 ÷ IN6 at 0.

- Verify the Ready output (RDY) value and, if the DRCS drive is ready, generate a pulse (minimum width of 2ms) on the

strobe input (STB).

- When the movement starts, the In Position output (POS) is deactivated and the Busy output (BSY) is activated until the

motion ends.

- When the motion ends, the In Position output (POS) becomes active, the Busy output (BSY) is deactivated.

• The user must adopt the necessary measures to prevent damage to the system caused by voltage spikes on the power lines

as a result of power outages of high-energy equipment.

• The DRCS board does have protection against reverse polarity of the power supply voltage.

• To improve noise immunity and prevent damage, it is recommended to connect the device to the system ground using any

of the holes in the aluminium body, and attaching the conductor to the metal plate.

• Only for models DRCS-XXX-X-C-X-X, it is possible to set the node address, its baud rate (up to 1 M/s) and enable the

CANopen communication mode (disabled by default) via the QSet configuration software (for more details on using the

configurator, specifically this feature, refer to the manual).

If the DRCS drive is the last node of the CANopen segment, it is necessary to use the termination resistor for the bus: the

order code EC-060623 is for a DRCS drive that has this resistor installed, which can be mounted on one of the two

CANopen connectors.

• To configure the DRCS drive, download the QSet software setup file from http://www.camozzi.com and proceed with

installation following the on-screen instructions. For more details, please refer to the QSet manual.

The connection to the DRCS drive is standard Micro USB (available as an accessory: G11W-G12W-2); communication

is only possible if the USB driver is correctly installed on PC.

The USB driver is installed automatically during the QSet installation.

7.11 PC requirements

• On start-up of the QSet software, the system verifies communication between the DRCS drive and the PC where the

configuration software is installed. In the event of communication failure, an error message is displayed.

Type of fault Cause Solution

Communication failure

between DRCS drive and PC

Power supply not connected Connect the electrical power supply

USB cable not connected Connect the USB cable to one of the ports available

on the PC and to the Micro USB connector

USB driver not installed Contact the Camozzi technical assistance service

22

21

6

4

2

1

3V3

R62

180 5% 1/5W

+24V

NPN

A K

22

21

6

4

2

1

3V3

R62

180 5% 1/5W

+24V

PNP

22

21

6

4

2

1

3V3

R62

180 5% 1/5W

+24V NPN

A K

22

21

6

4

2

1

3V3

R62

180 5% 1/5W

+24V

PNP