Table of Contents

PDF viewers: These page numbers refer to the printed version of this document. Use the

PDF reader bookmarks tab for links to specific sections.

1. Introduction.................................................................1

2. Cautionary Statements...............................................1

3. Initial Inspection .........................................................2

4. Overview......................................................................2

5. Specifications .............................................................2

5.1 Measurements ......................................................................................2

5.2 Output Signals......................................................................................5

5.3 Physical Description.............................................................................5

5.4 Power Requirements During Power-up and Operation ........................6

6. Installation...................................................................6

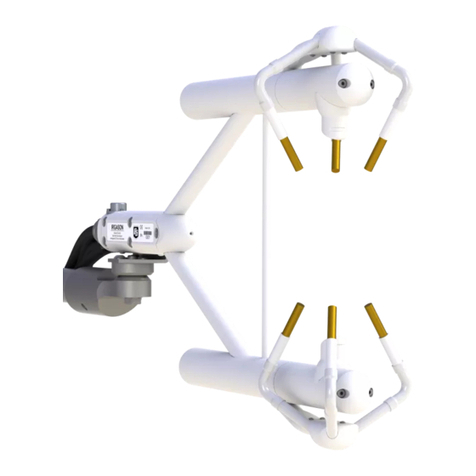

6.1 Orientation ...........................................................................................6

6.2 Mounting..............................................................................................6

6.3 Wiring and Connections.....................................................................11

7. Settings......................................................................14

7.1 Factory Defaults.................................................................................14

7.2 Details ................................................................................................15

7.2.1 SDM Address..............................................................................15

7.2.2 Bandwidth...................................................................................15

7.2.3 Unprompted Output ....................................................................15

7.2.4 Unprompted Output Rate ............................................................15

7.2.5 RS-485 Baud Rate.......................................................................16

7.2.6 Analog Output.............................................................................16

7.2.7 ECMon Update Rate ...................................................................16

7.2.8 Temperature Sensor ....................................................................16

7.2.9 Fixed Temperature Value............................................................16

7.2.10 Pressure Sensor ...........................................................................16

7.2.10.1 Pressure Gain....................................................................17

7.2.10.2 Pressure Offset .................................................................17

7.2.10.3 Fixed Pressure Value........................................................17

7.2.11 Pressure Differential Enable .......................................................17

7.2.12 Heater Control.............................................................................17

7.3 ECMon...............................................................................................17

7.4 Device Configuration Utility..............................................................19

i