2

ADJUSTMENTS

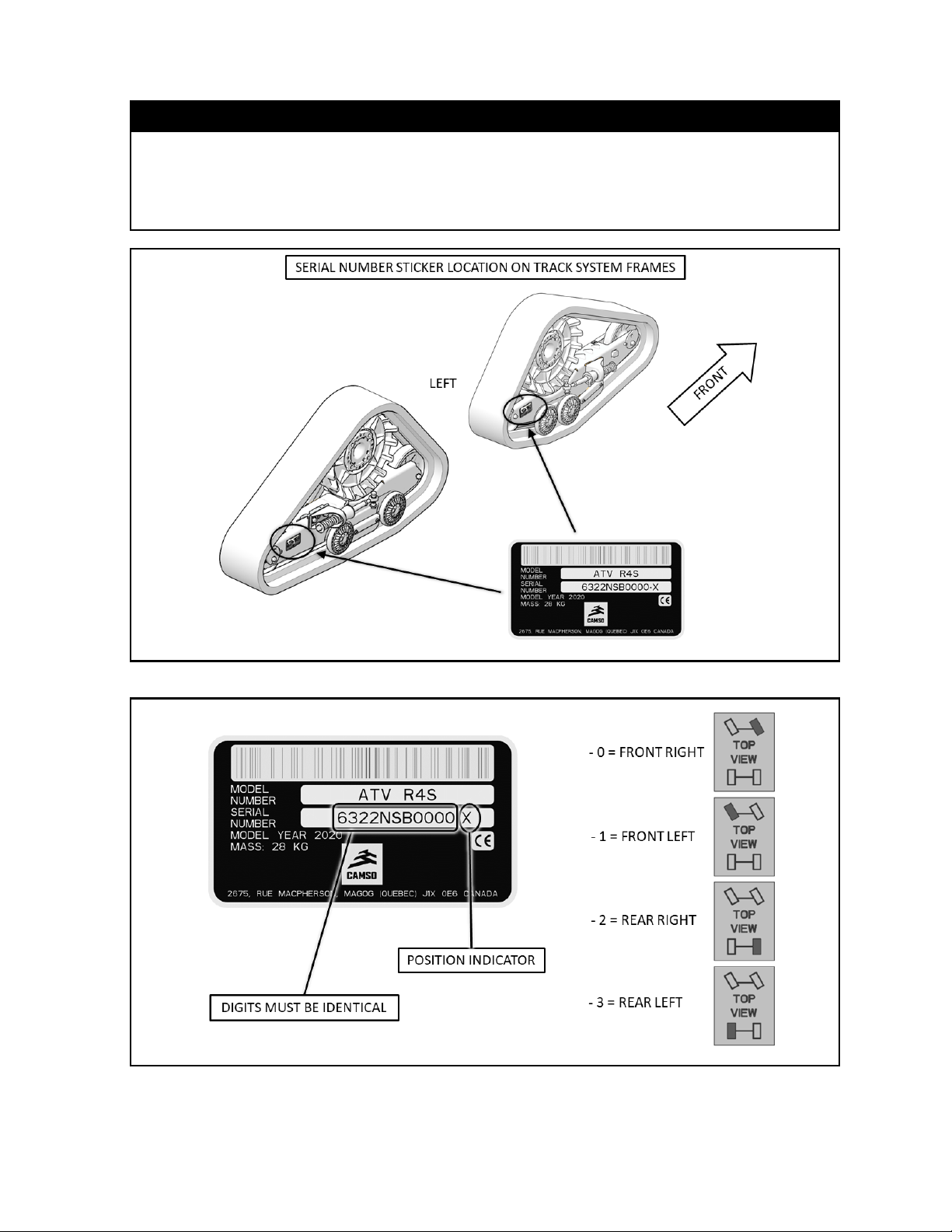

• Position a flat bar on top of the rear wheels of

the front Track System and measure from the

ground up to the flat bar as shown on Figure 7.

Figure 7

CAUTION: The 254 mm dimension corresponds to

the required angle of attack setting. If the centered

bubble in the level does not produce the required

measurement of 254 mm, re-adjust angle of attack

to obtain the required dimension without referring

to the bubble level.

NOTE: Once angle of attack adjustment on front

systems is completed, verify once more to

confirm adjustment setting.

BASIC TUNING (Front Track Systems)

• An adjustment of more than 254 mm [10 in],

measured with the flat bar, provides easier

steering but produces a wobbling effect at high

speed.

• An adjustment of less than 254 mm [10 in],

measured with the flat bar, results in harder

steering and more stability at high speed.

ANGLE OF ATTACK - REAR SYSTEMS

To obtain the correct angle of attack on rear Track

Systems, perform the following:

RIGID AXLE OR TRAILING ARM SUSPENSION

CAUTION: Some vehicles require a particular

adjustment. Refer to the Installation Guidelines

specific to your vehicle model to confirm the

adjustment.

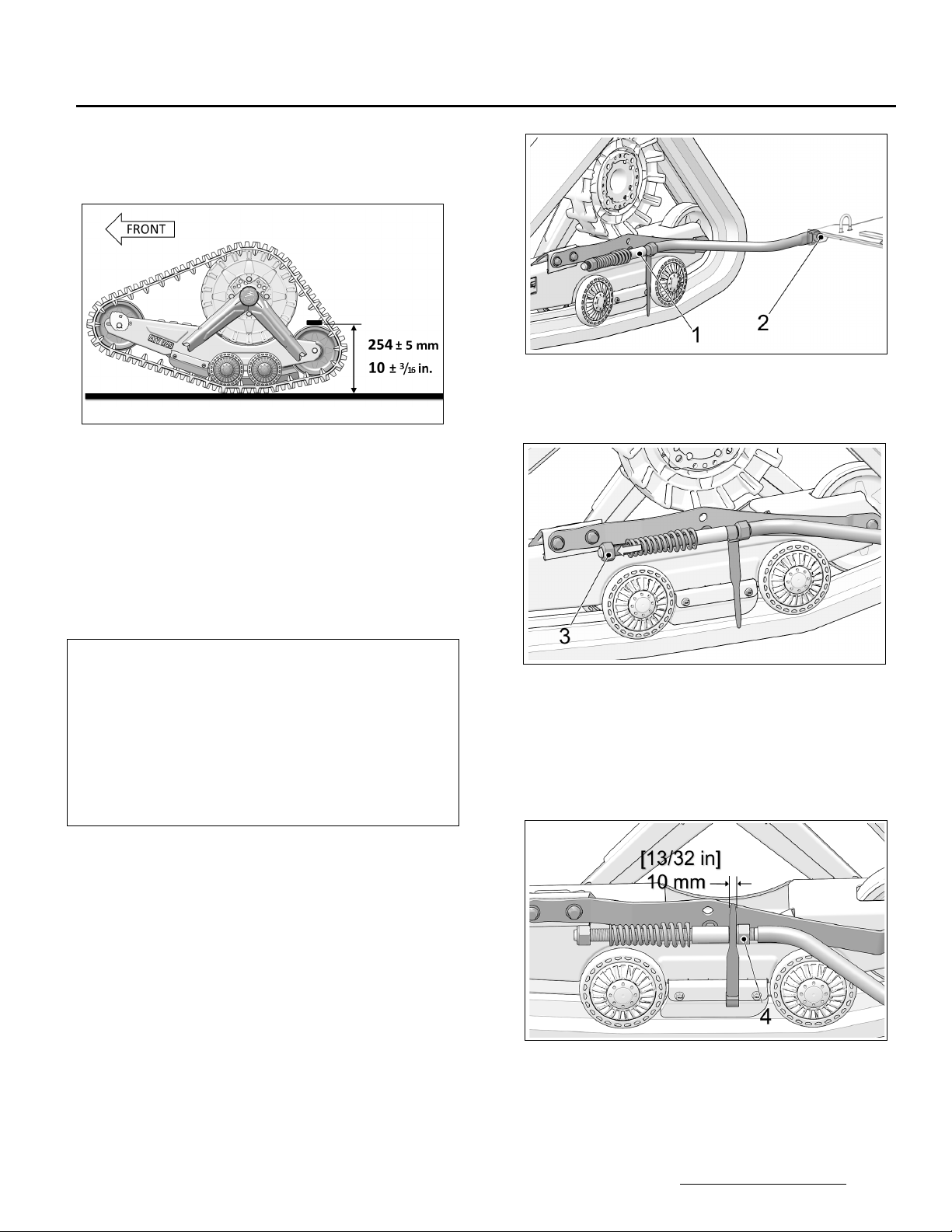

• Stabilizing arm (1) must be attached to Track

System and to rear anchor bracket (2) installed

on vehicle. See Figure 8.

Figure 8

• Loosen nut (3) compressing stabilizing rod

spring. See Figure 9.

Figure 9

NOTE: Use narrow part of adjusting template provided

with stabilizing arm to make adjustment.

• Set nut (4) to obtain a distance of 10 mm

between nut and stabilizing arm guide as

shown on Figure 10.

Figure 10

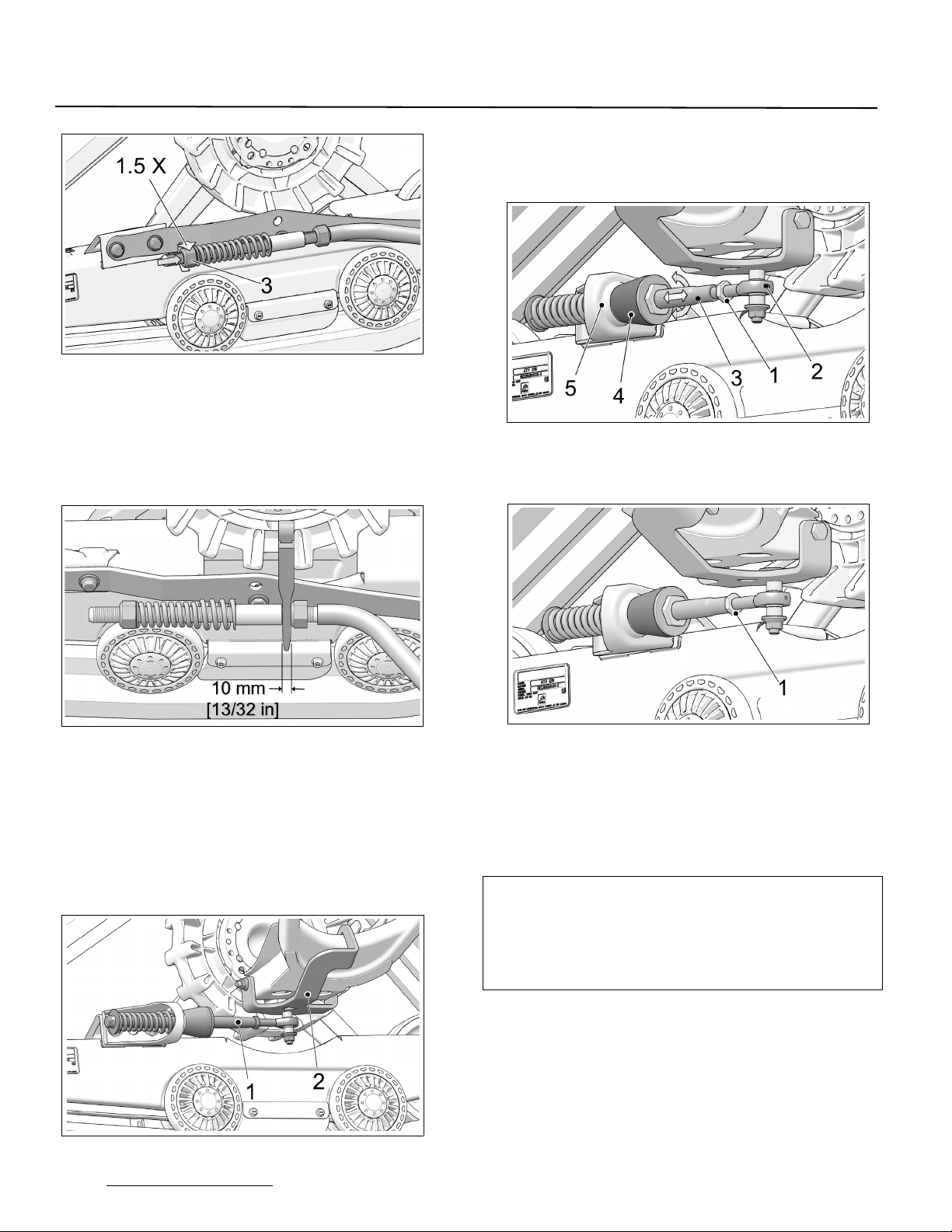

• Turn nut (3) until it comes in contact with spring,

then compress spring by turning nut 1 1/2 turn.

See Figure 11.