COPYRIGHT

©

1999 CANON INC. CANON FINISHER - D1 REV.0 FEB. 1999 PRINTED IN JAPAN (IMPRIME AU JAPON)

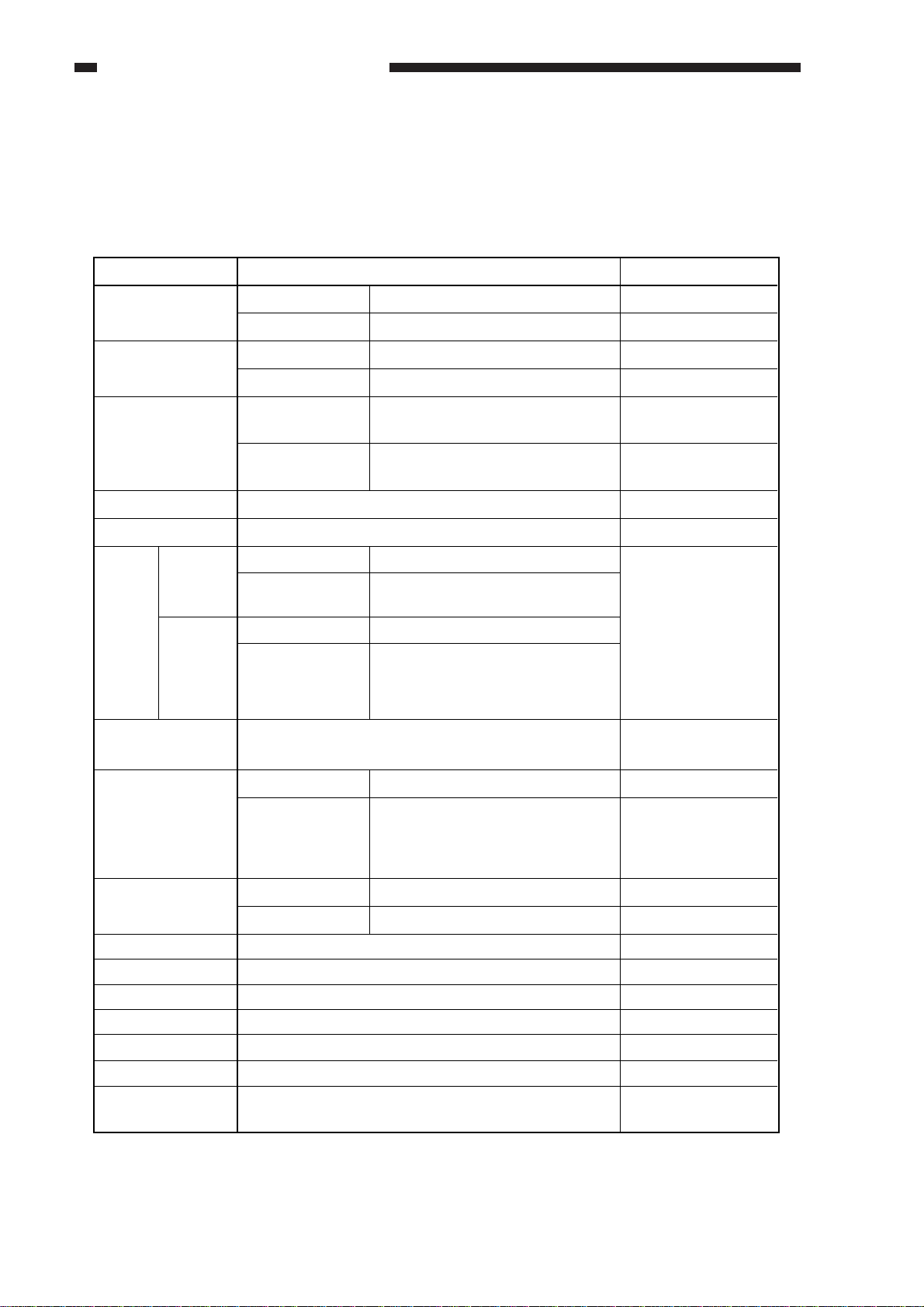

CHAPTER 1 GENERAL DESCRIPTION

I. FEATURES ................................1-1

II. SPECIFICATIONS......................1-2

A. Specifications ........................1-2

B. Cross Section ........................1-4

III. OPERATING THE FINISHER ....1-5

A. Removing Jams from The

Finisher..................................1-5

B. Removing Jams in Sort, Group, or

Staple Sort Mode ...................1-7

C. Replacing the Staple Cartridge

.............................................1-10

D. Removing Staple Jams in the

Stapler Unit ..........................1-13

IV. MAINTENANCE BY THE USER

..................................................1-15

CONTENTS

CHAPTER 2 OPERATIONS

I. BASIC OPERATIONS ................2-1

A. Specifications ........................2-1

B. Outline of Electrial Circuitry ...2-2

C. Inputs to and Outputs from the

Finisher Controller PCB.........2-3

II. FEEDING/DRIVE SYSTEM......2-14

A. Outline..................................2-14

B. Feeding/Delivery .................2-19

C. Job Offset .............................2-22

D. Releasing the Knurled Belt

............................................ 2-29

E. Buffer Path ...........................2-34

III. CONTROLLING THE PADDLE

..................................................2-39

IV. CONTROLLING THE TRAY

AUXILIARY PLATE ..................2-40

V. STAPLING ................................2-42

VI. TRAY MOVEMENT ..................2-50

VII. FANS ........................................2-54

VIII. POWER SUPPLY.....................2-56

IX. DETECTING JAMS ..................2-59

CHAPTER 3 MECHANICAL SYSTEM

I. EXTERNALS AND CONTROLS

....................................................3-1

II. PROCESSING TRAY UNIT .....3-13

III. TRAY B UNIT ...........................3-21

IV. KNURLED BELT RELEASING UNIT

..................................................3-28

V. KNURLED BELT ......................3-30

VI. BUFFER ROLLER UNIT ..........3-31

VII. STAPLER UNIT........................3-35

VIII. PCBs.........................................3-42