08

22

SX-280 SQUEEZEBOX PRESS

OWNER’S MANUAL

Section 4: Operation

SAFETY GLASSES must be worn at all times during operation.

Beware of all pinch-points and moving parts.

Pressure factory set at 1800psi for extend and 2200 psi for retract (do not adjust).

4.1 PRESS OPERATION

1

2

3

4

5

6

7

8

9

10

Check to make sure all components are in place as described in the installation section.

Turn the disconnect switch to the “ON” position and pull the “E-Stop” button out to start the motor and pump.

Turn directional switch to the forward or reverse position until it stops (the motor and pump will continue to run). The

press does not need to be turned o when it is at full press stage, as there is a built-in override system which is designed to

maintain constant pressure without damaging the press.

Fill the open side of the press with slurry using a suitable pump. Do not fill one bag at a time, fill them uniformly.

Fill the bags 2’’ to 3” from the top.

Turn the switch to the forward or reverse position to press slurry. After pressing is complete allow the press to hold for

about 2 minutes longer to ensure full extraction.

The open side of the press is now ready to be filled. Repeat steps 3,4, and 5.

Turn the switch in the appropriate direction to begin squeezing the side just filled.

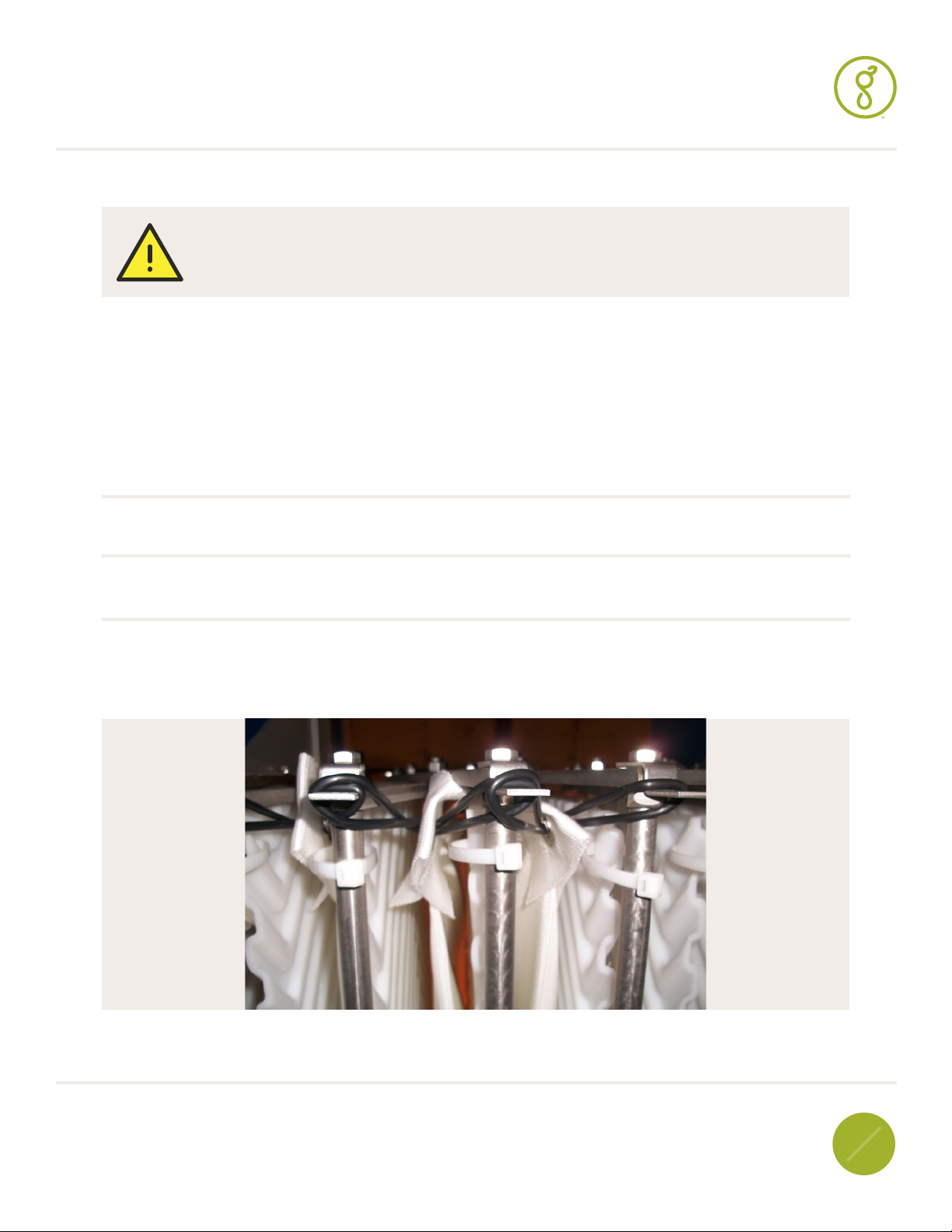

As the side previously pressed opens, gently work the cake separator between the bag and dry cake on both sides of the

cake on all layers.

Be careful not to wear bottoms and sides of the bags by jamming the cake separator into the layers. Re- member to always use

your cake separator to loosen the cakes in the bags before dumping! Caution should be used in order not to cut the seam on the

sides of the bags. Always be sure all edges of the cake separator are smooth, without nicks or sharp edges. Never force the cake

separator. Gently cutting the cakes in half will allow for an easier dump and increase the life of the bags.

When all cakes have been separated from the bag, press the “lift” button to raise and dump the dry cake from the bags.

When the bags are empty, flip the press area back over and repeat. The “lift” button must be released when the press area

reaches its pivot point in order to fall over.