CANTERBURY ARENA Z3314-44 User manual

Other CANTERBURY Plumbing Product manuals

CANTERBURY

CANTERBURY Nicolazzi Z1458WS User manual

CANTERBURY

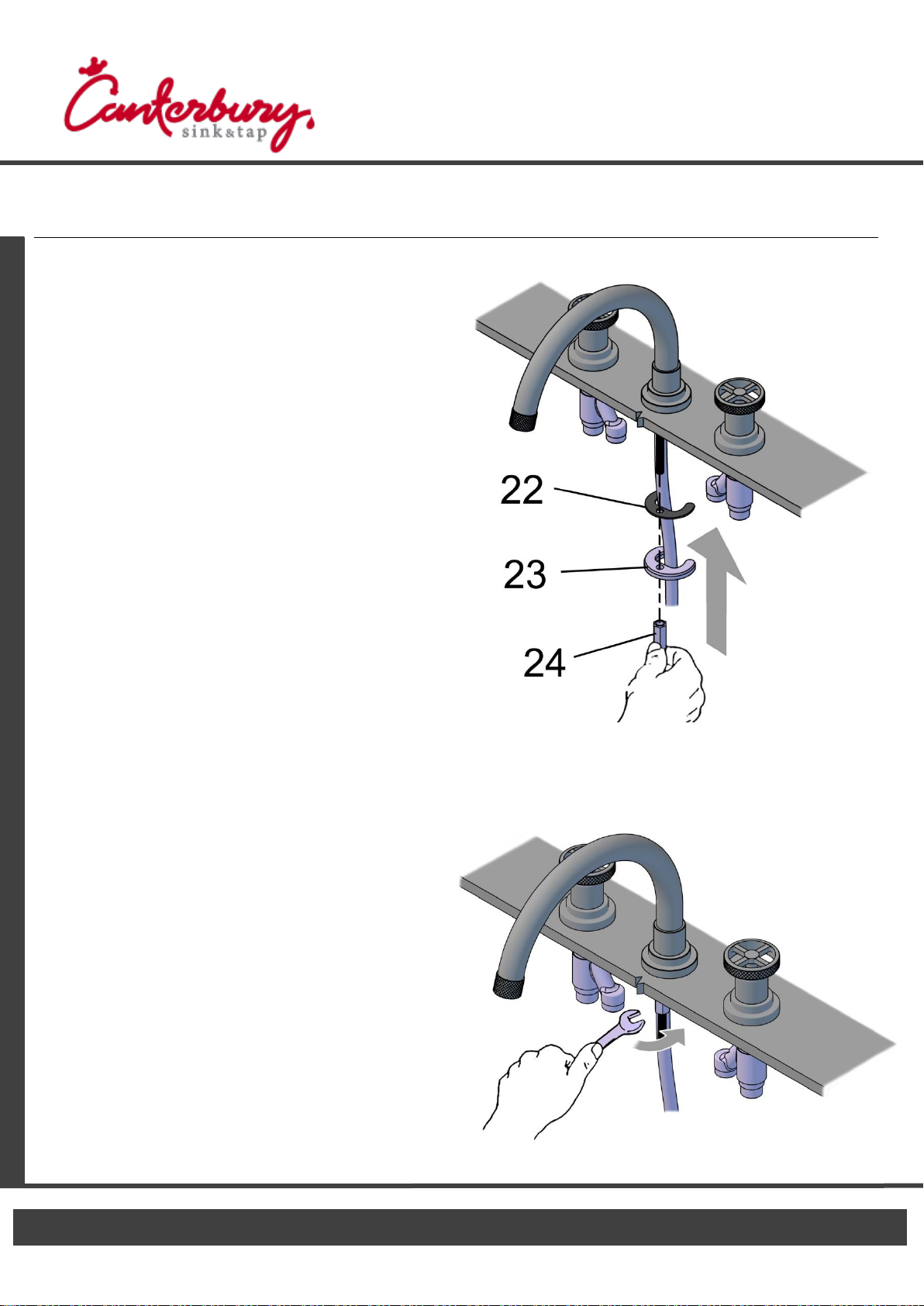

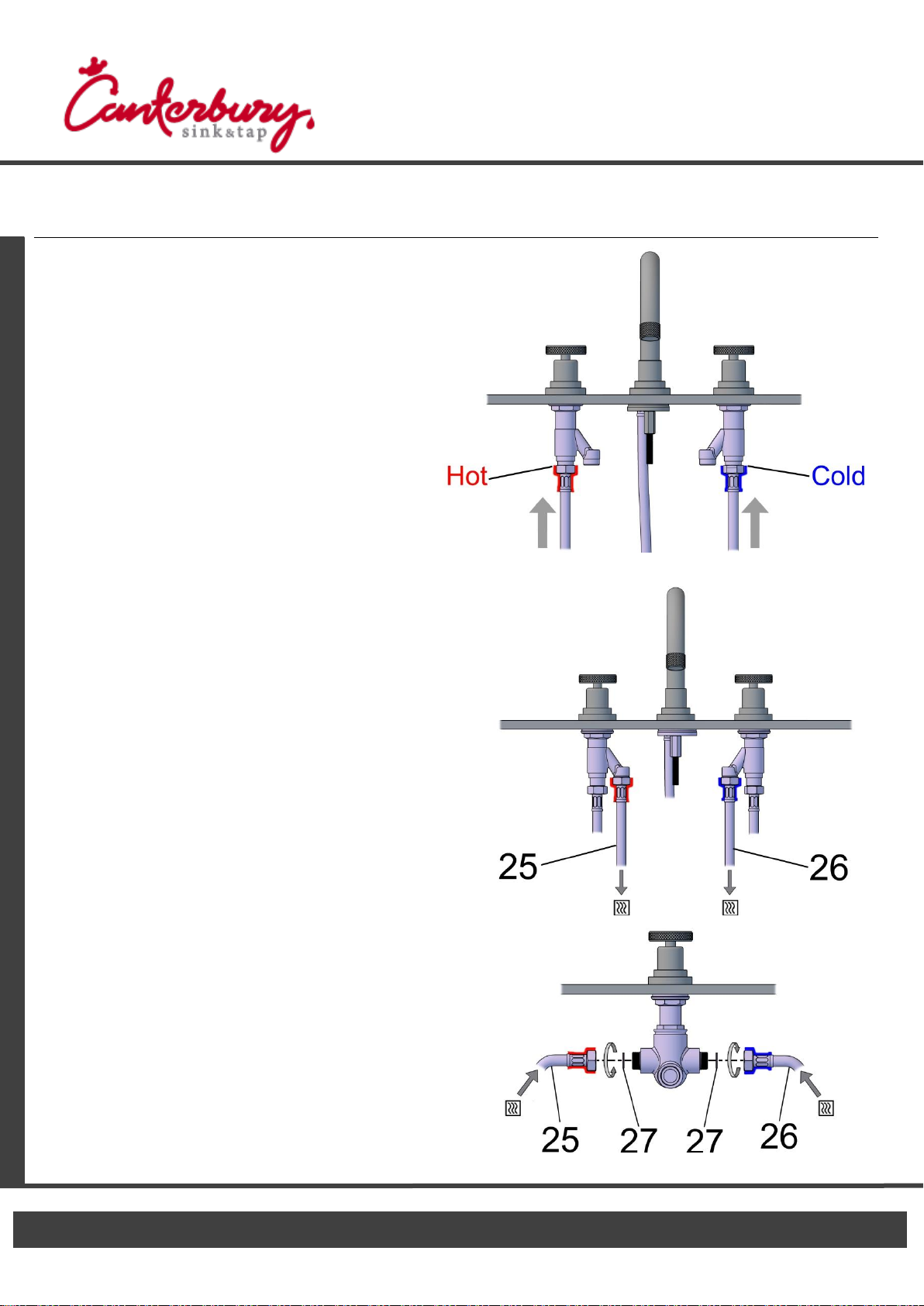

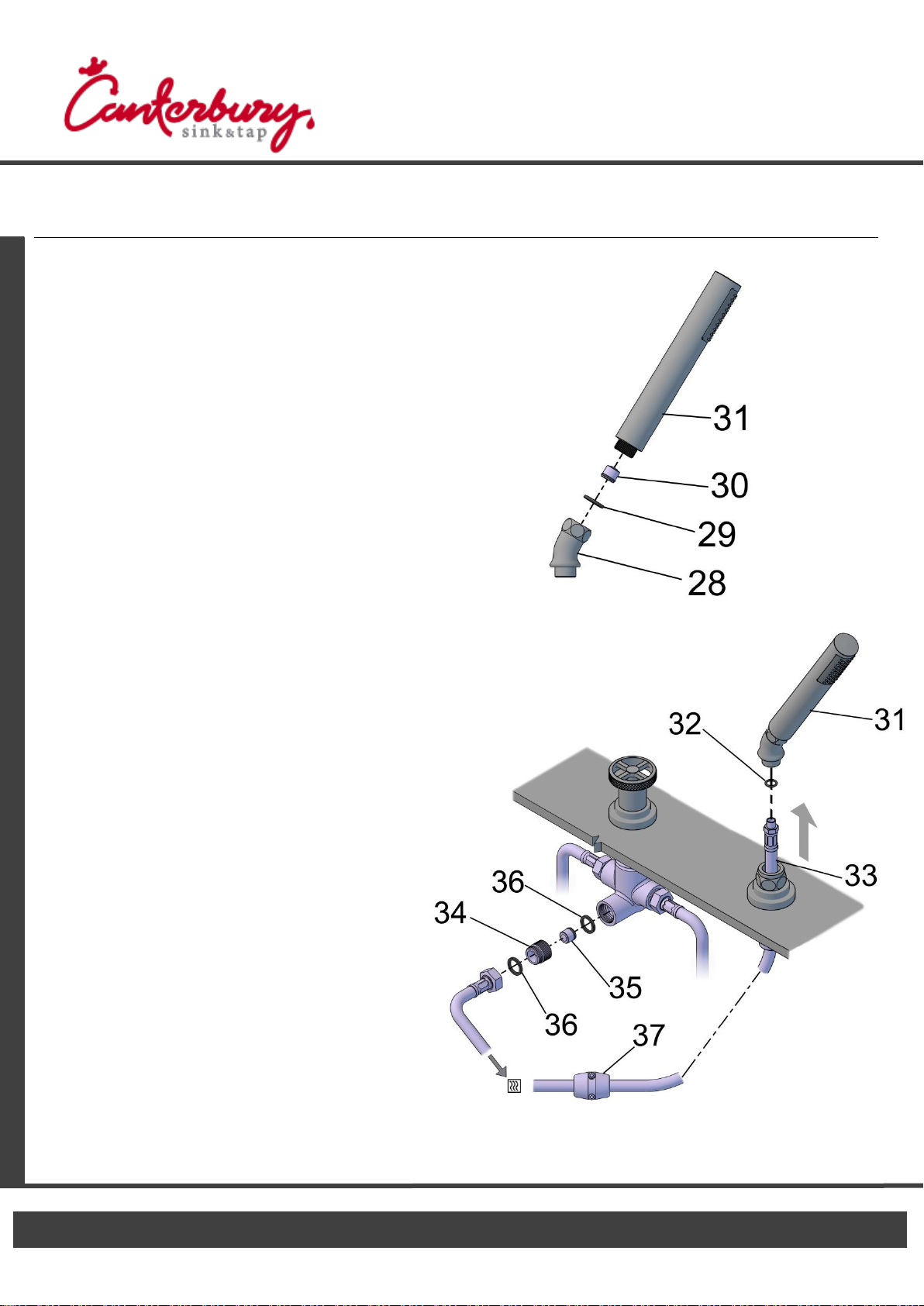

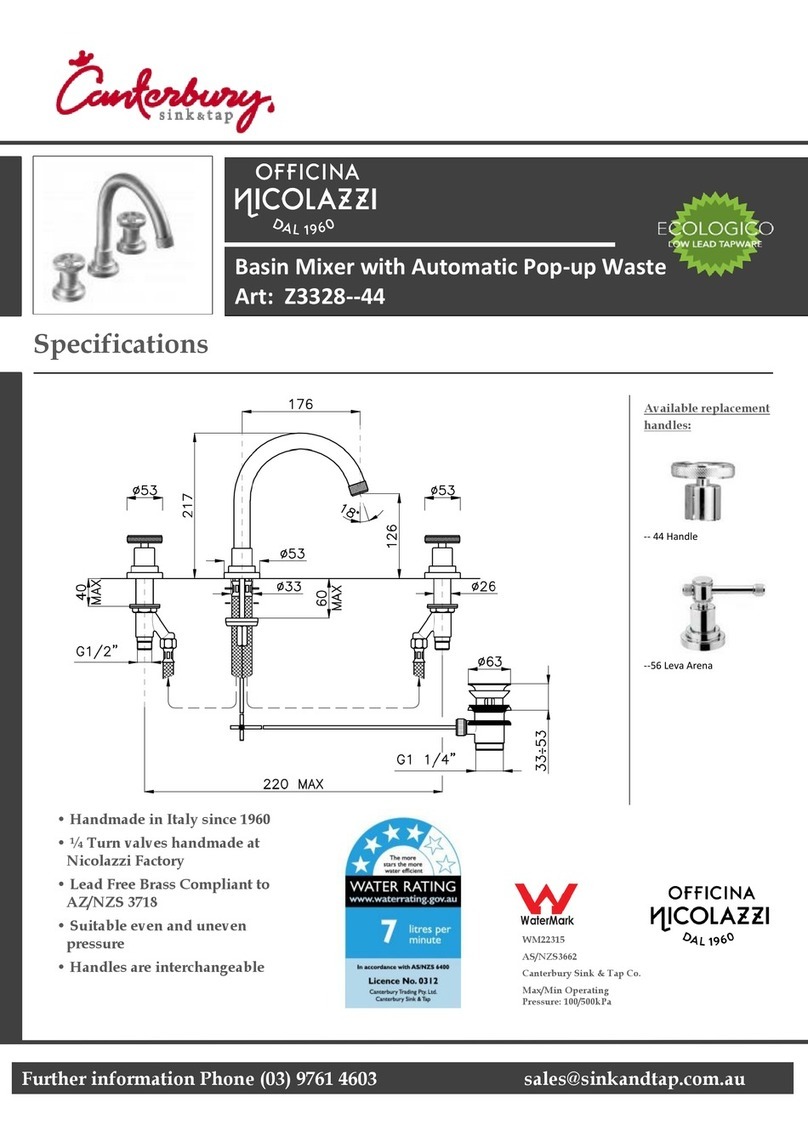

CANTERBURY Z3328-44 User manual

CANTERBURY

CANTERBURY OFFICINA NICOLAZZI Z1459 User manual

CANTERBURY

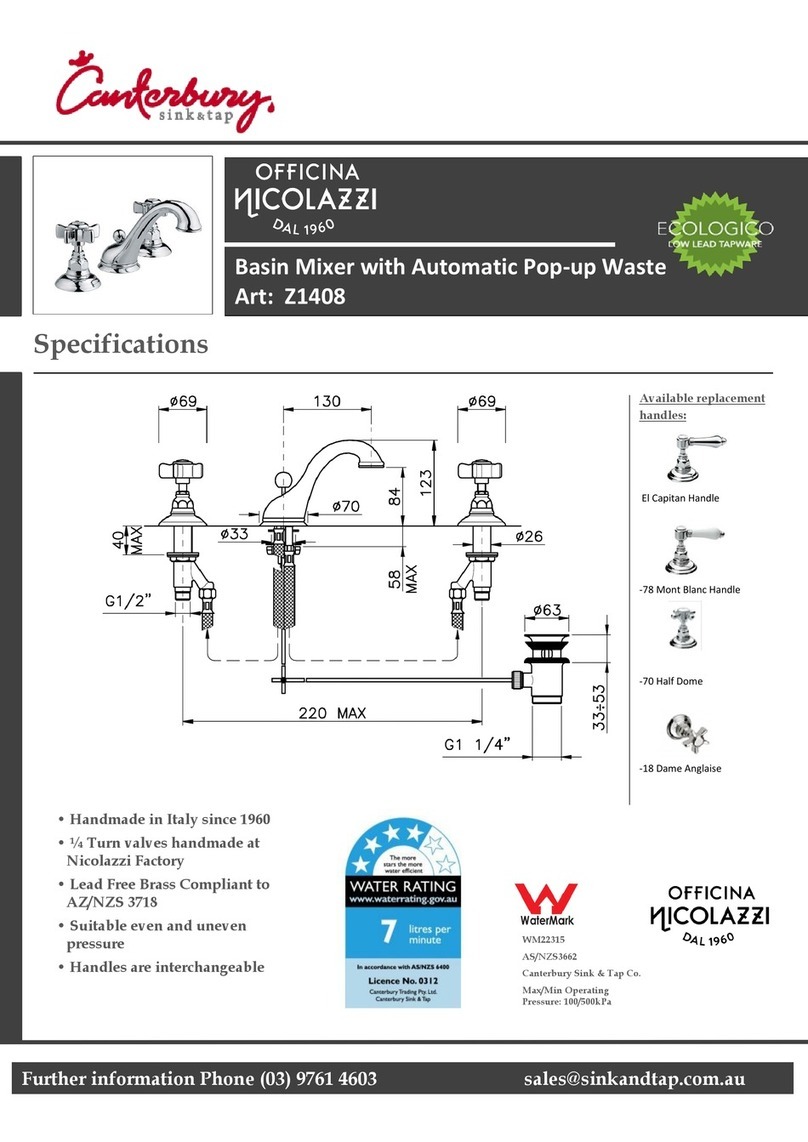

CANTERBURY Z1408 User manual

CANTERBURY

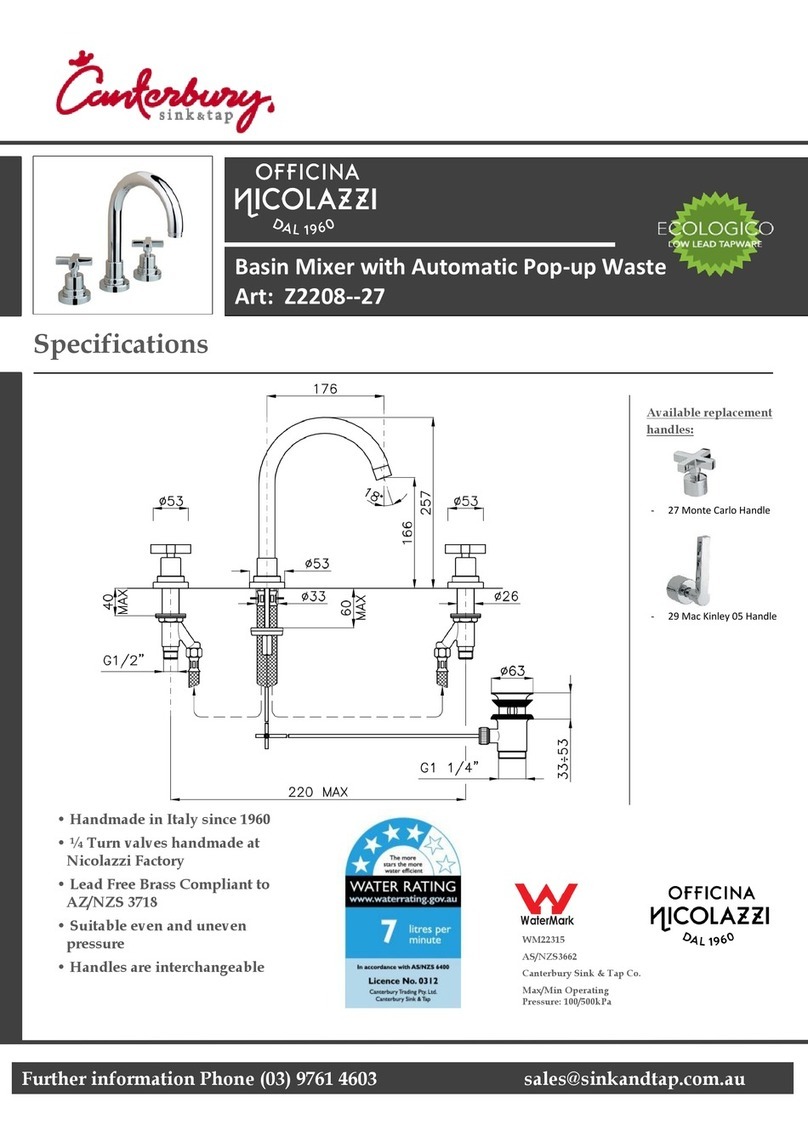

CANTERBURY Z2208--27 User manual

CANTERBURY

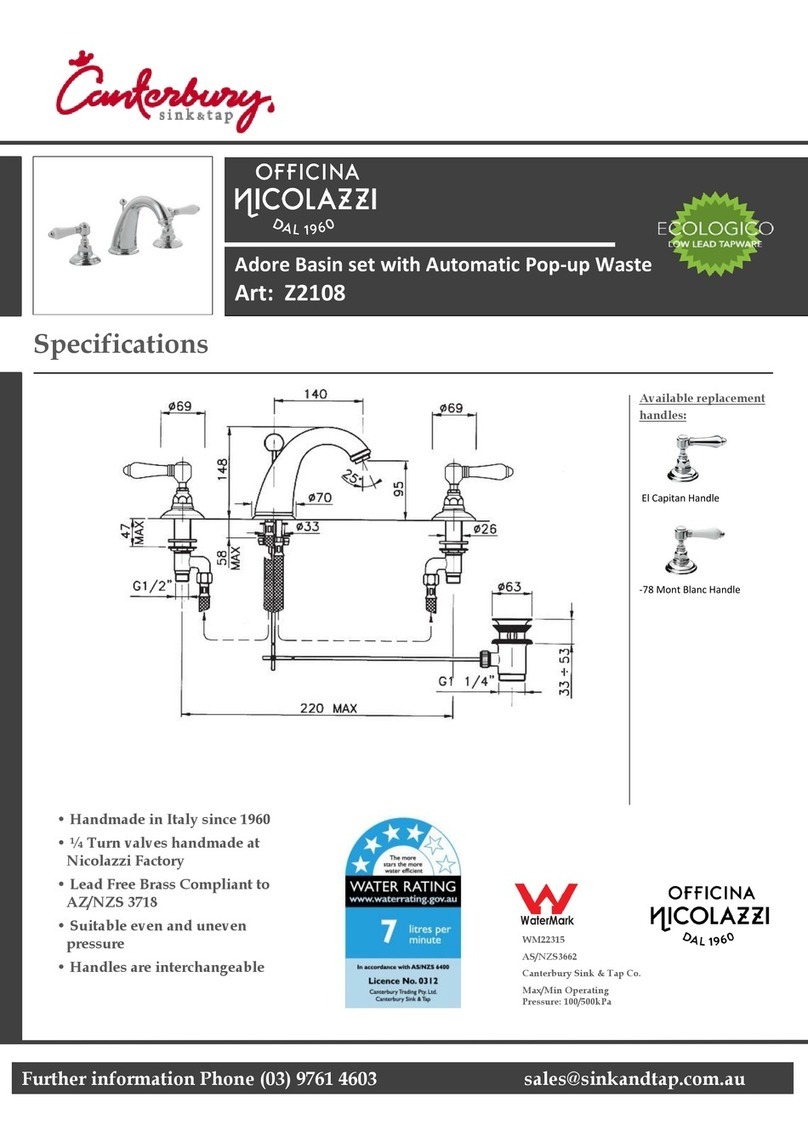

CANTERBURY OFFICINA NICOLAZZI Z2108 User manual

CANTERBURY

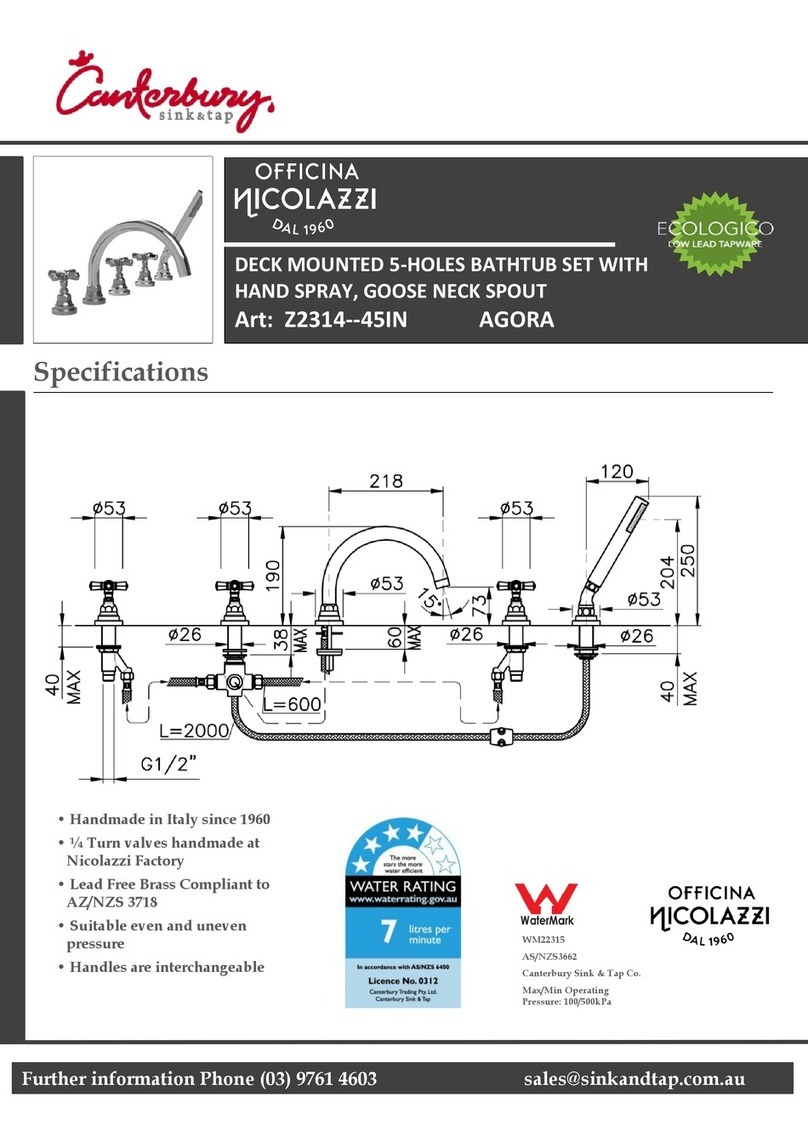

CANTERBURY AGORA Z2314-45IN User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide