CANTERBURY Z2208--27 User manual

Other CANTERBURY Plumbing Product manuals

CANTERBURY

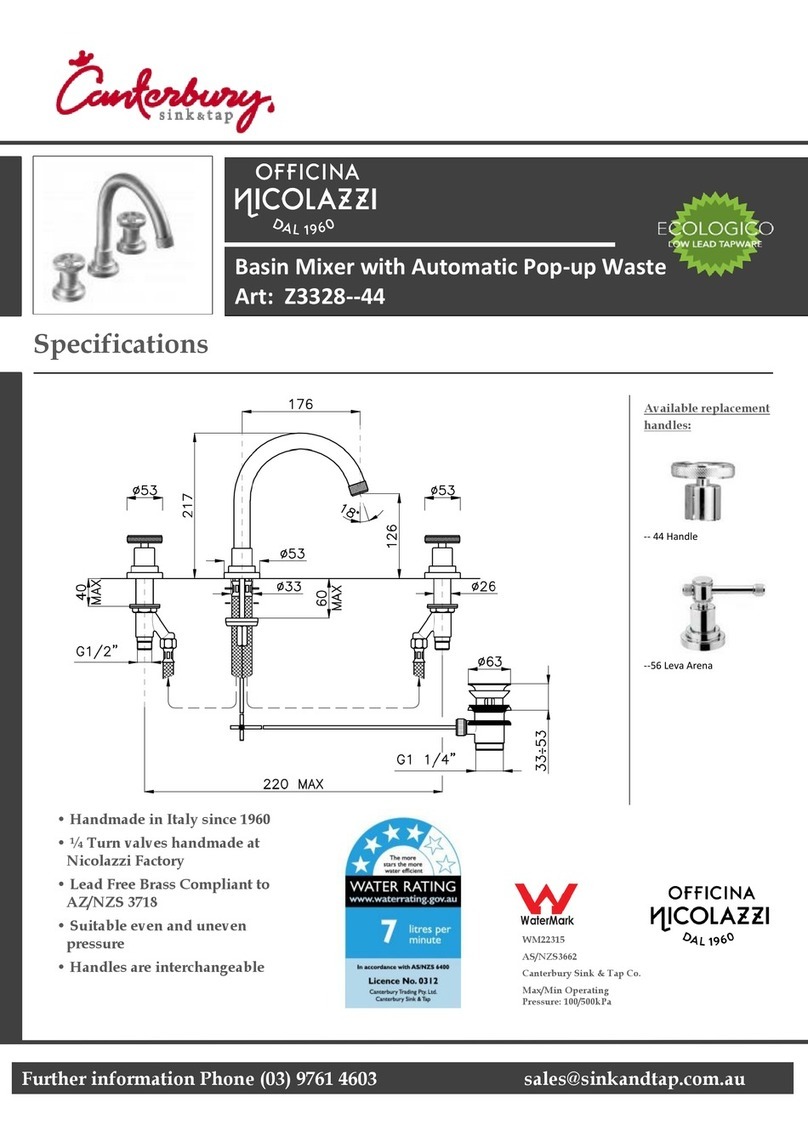

CANTERBURY Z3328-44 User manual

CANTERBURY

CANTERBURY Nicolazzi Z1458WS User manual

CANTERBURY

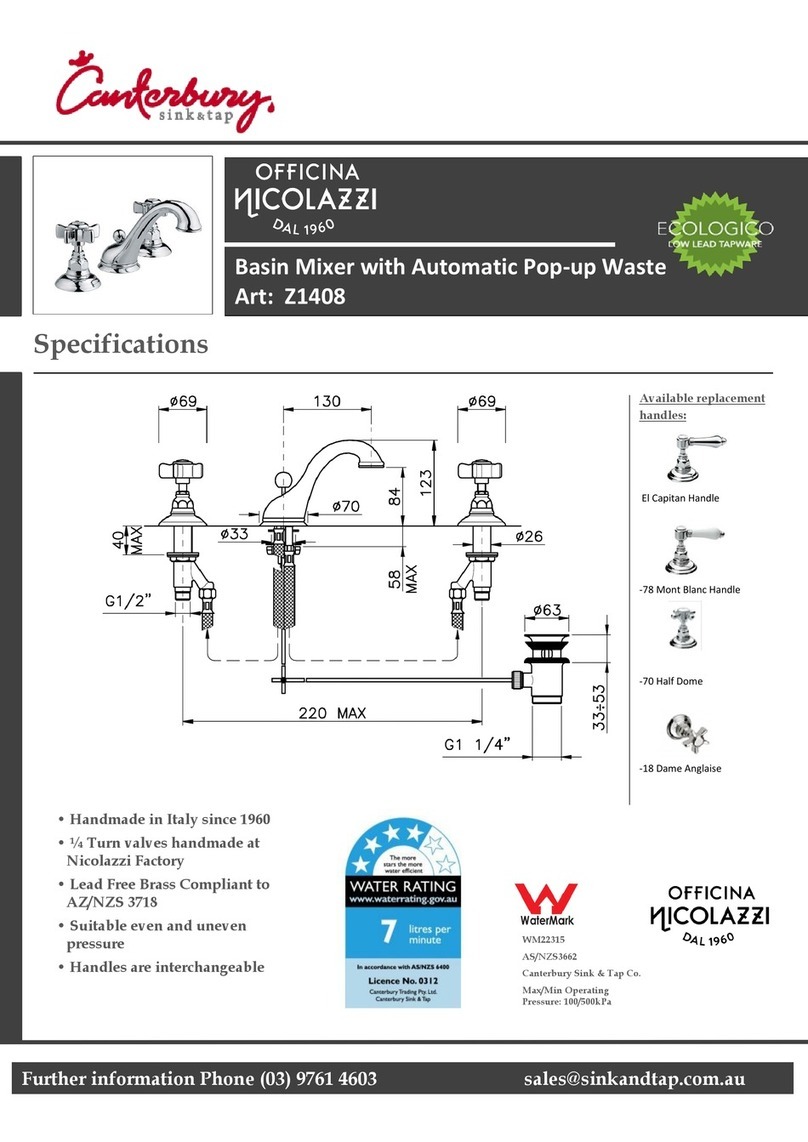

CANTERBURY Z1408 User manual

CANTERBURY

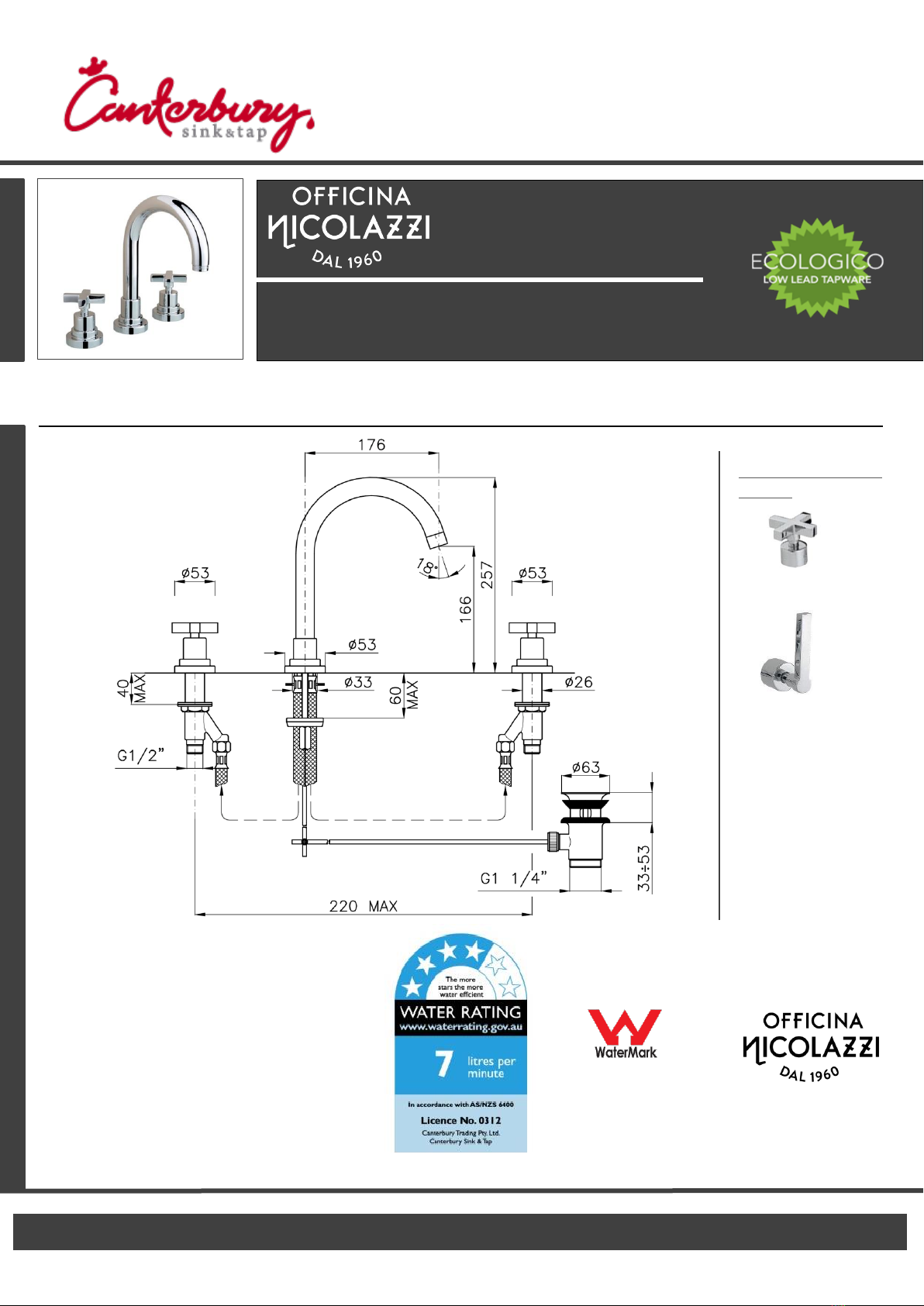

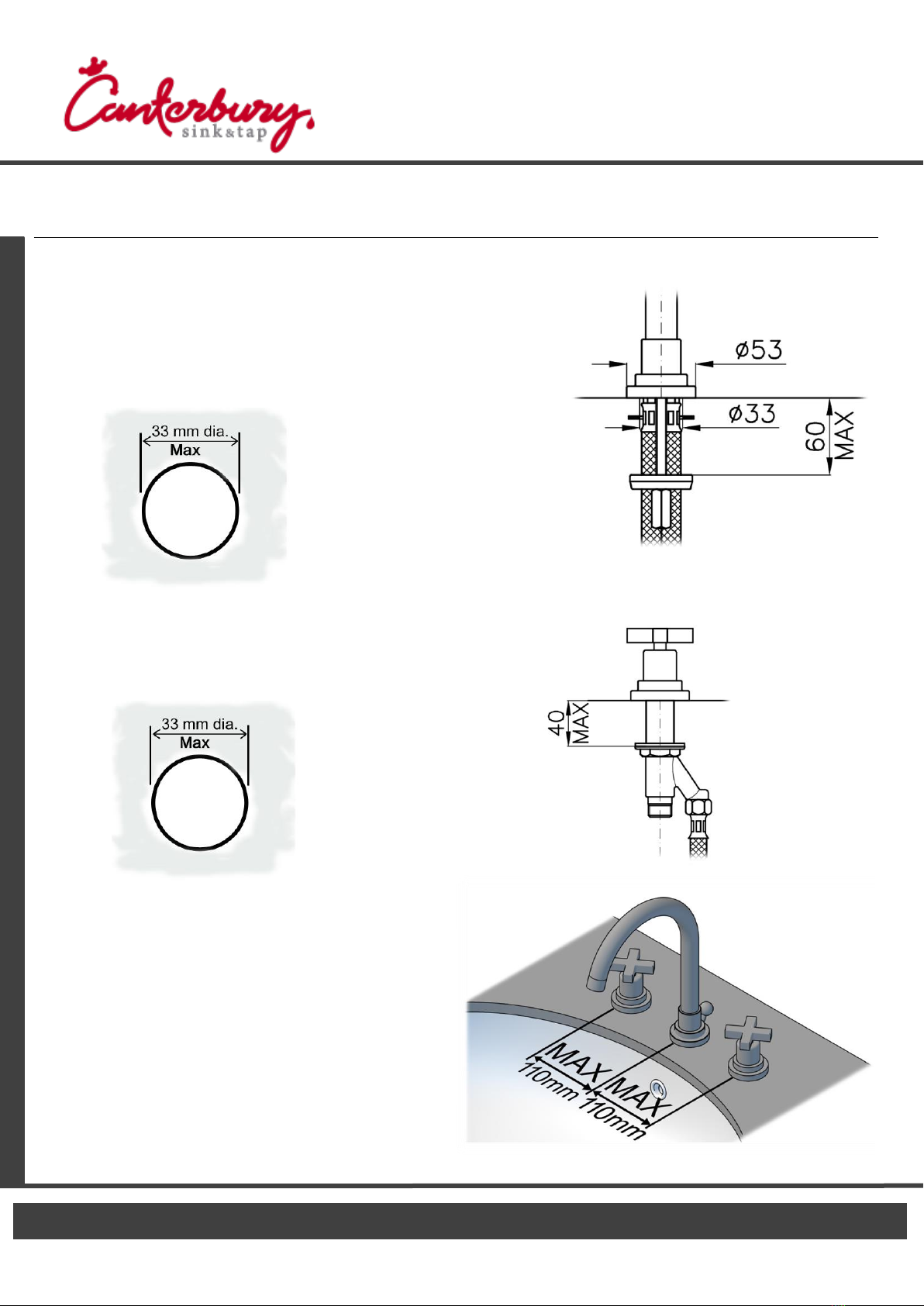

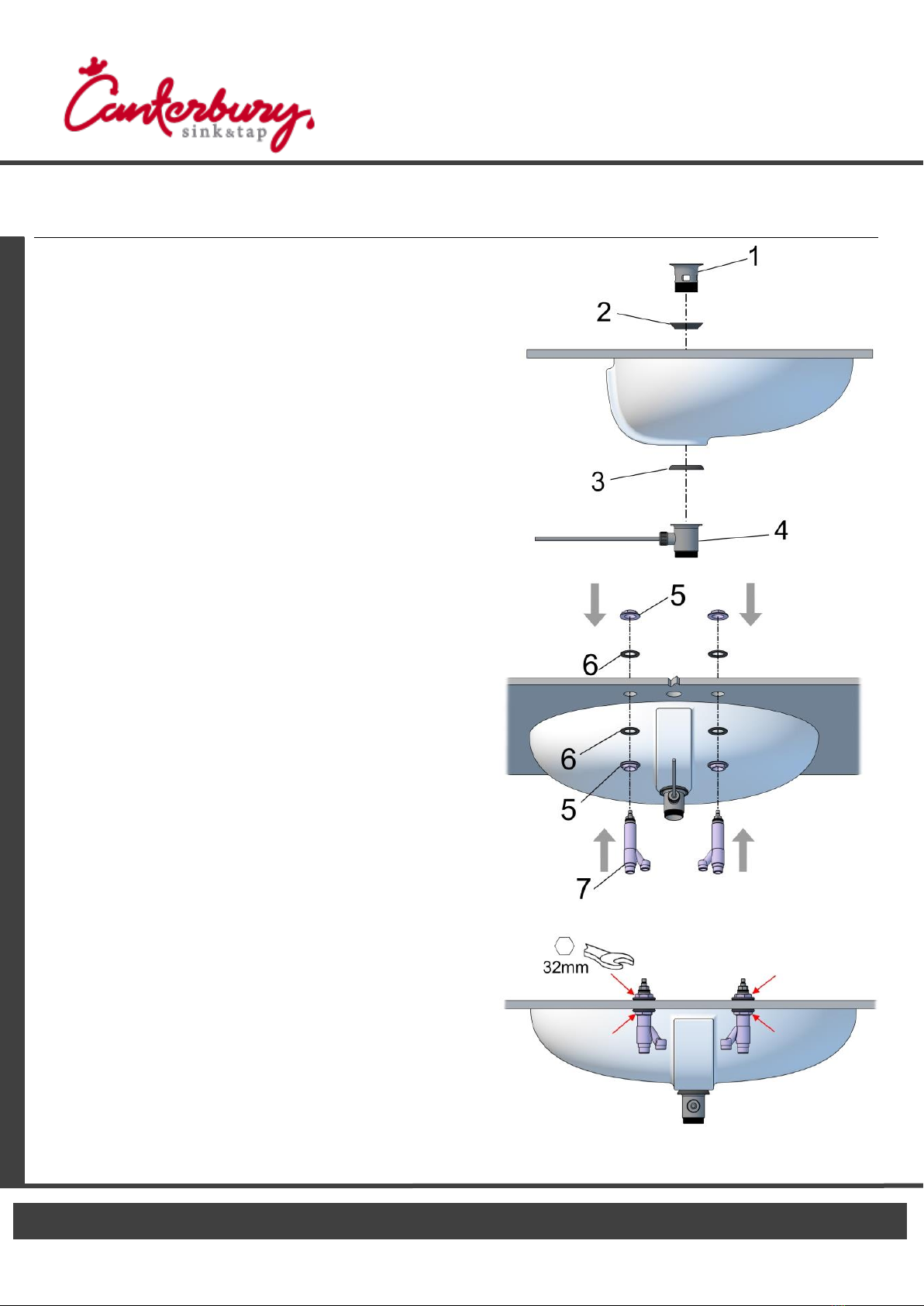

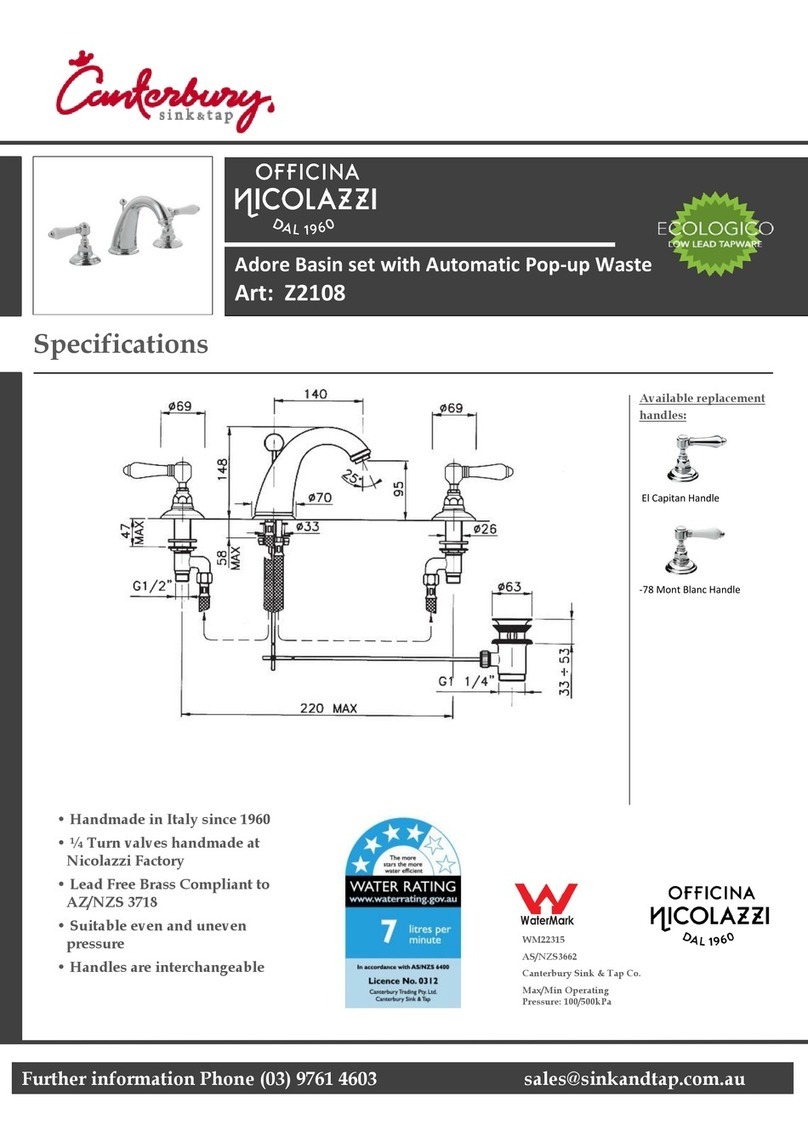

CANTERBURY OFFICINA NICOLAZZI Z2108 User manual

CANTERBURY

CANTERBURY OFFICINA NICOLAZZI Z1459 User manual

CANTERBURY

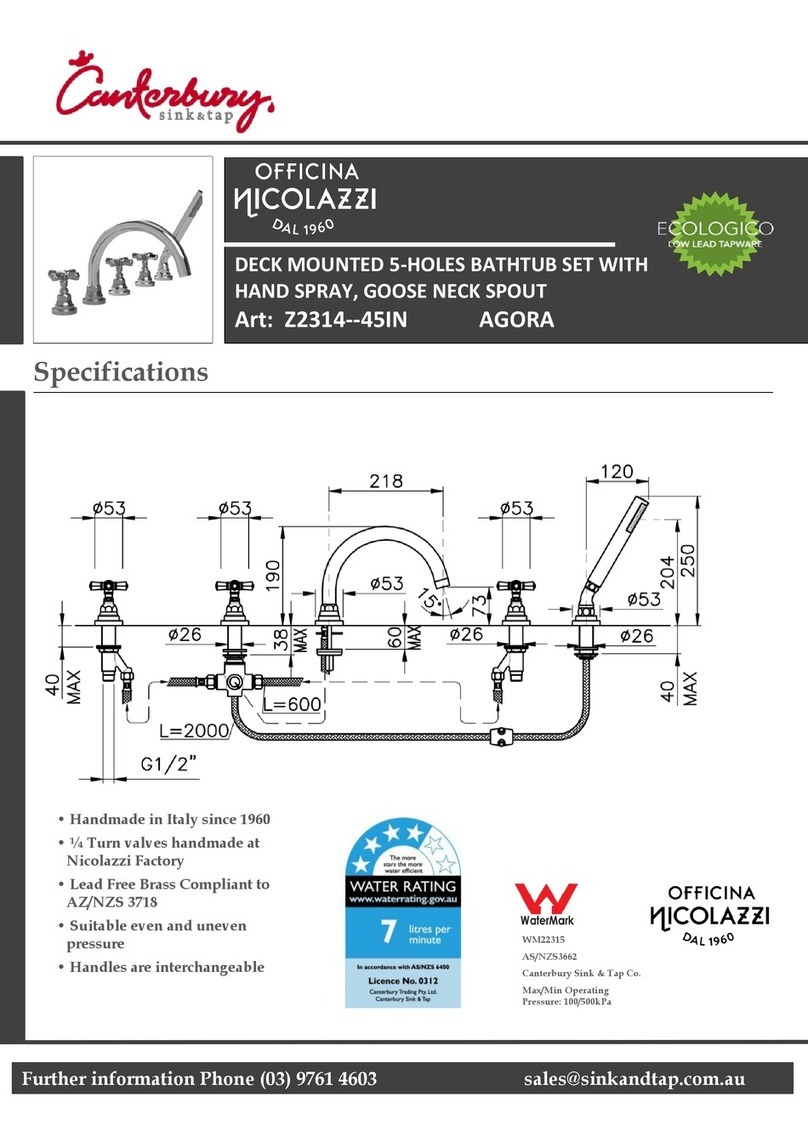

CANTERBURY AGORA Z2314-45IN User manual

CANTERBURY

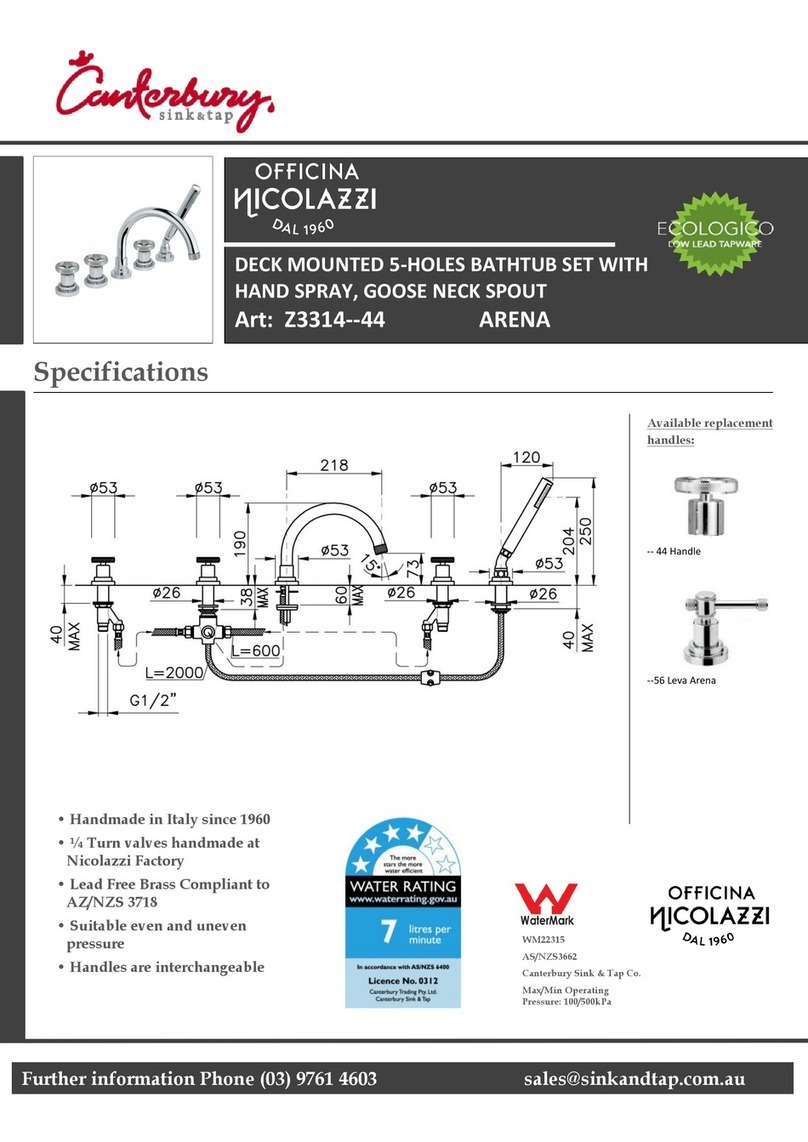

CANTERBURY ARENA Z3314-44 User manual

Popular Plumbing Product manuals by other brands

Weka

Weka 506.2020.00E ASSEMBLY, USER AND MAINTENANCE INSTRUCTIONS

American Standard

American Standard DetectLink 6072121 manual

Kohler

Kohler K-6228 Installation and care guide

Uponor

Uponor Contec TS Mounting instructions

Pfister

Pfister Selia 49-SL Quick installation guide

Fortis

Fortis VITRINA 6068700 quick start guide

Elkay

Elkay EDF15AC Installation, care & use manual

Hans Grohe

Hans Grohe AXOR Citterio E 36702000 Instructions for use/assembly instructions

baliv

baliv WT-140 manual

Kohler

Kohler Mira Eco Installation & user guide

BELLOSTA

BELLOSTA romina 0308/CC Installation instruction

Bristan

Bristan PS2 BAS C D2 Installation instructions & user guide