2

TABLE OF CONTENTS

ADDITIONAL ITEMS REQUIRED ...................2

Radio Equipment ..............................2

Hardware and Accessories ......................2

Adhesives and Building Supplies ..................2

Optional Supplies and Tools......................2

PREPARATION .................................2

ASSEMBLE THE WING ...........................3

INSTALL THE FIN ...............................3

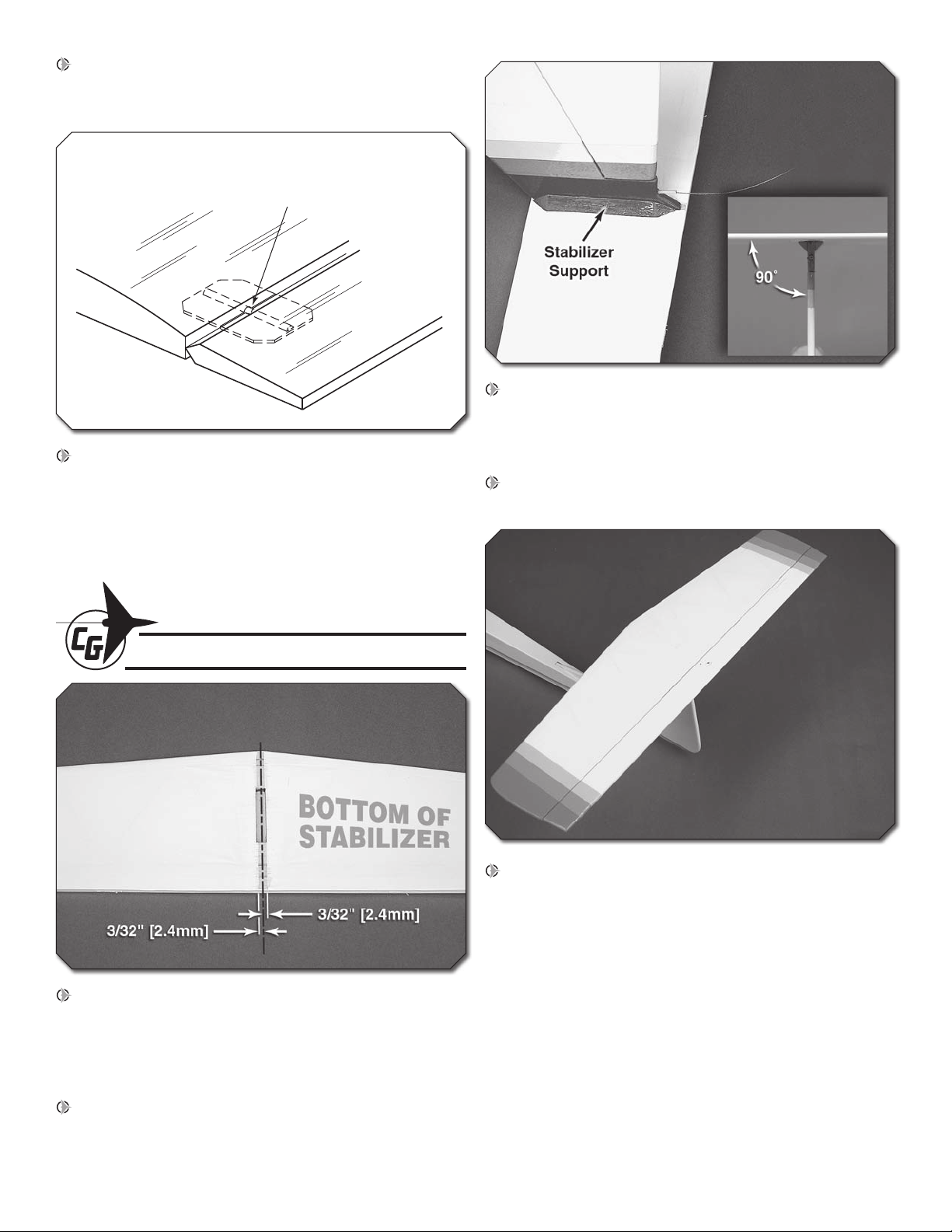

INSTALL THE STABILIZER ........................5

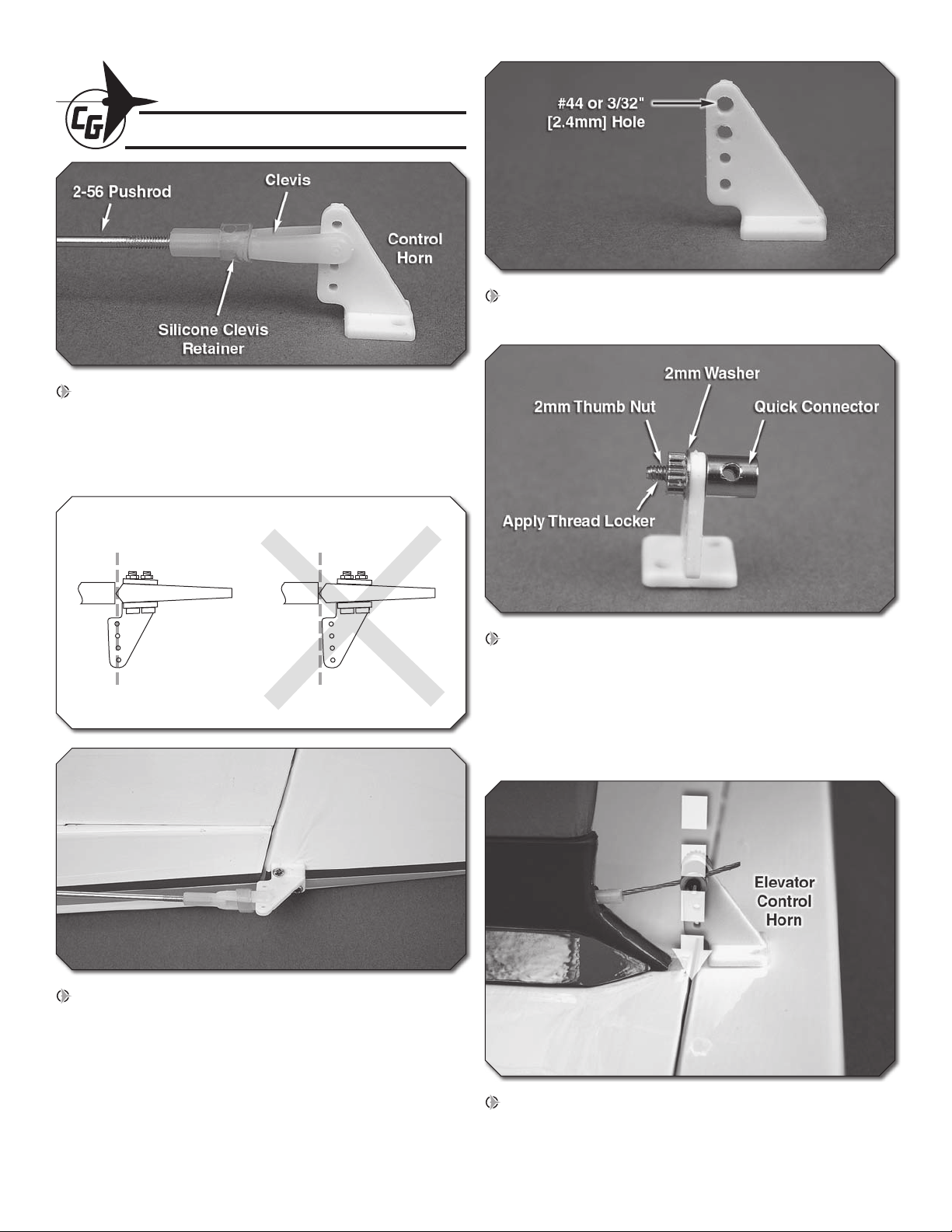

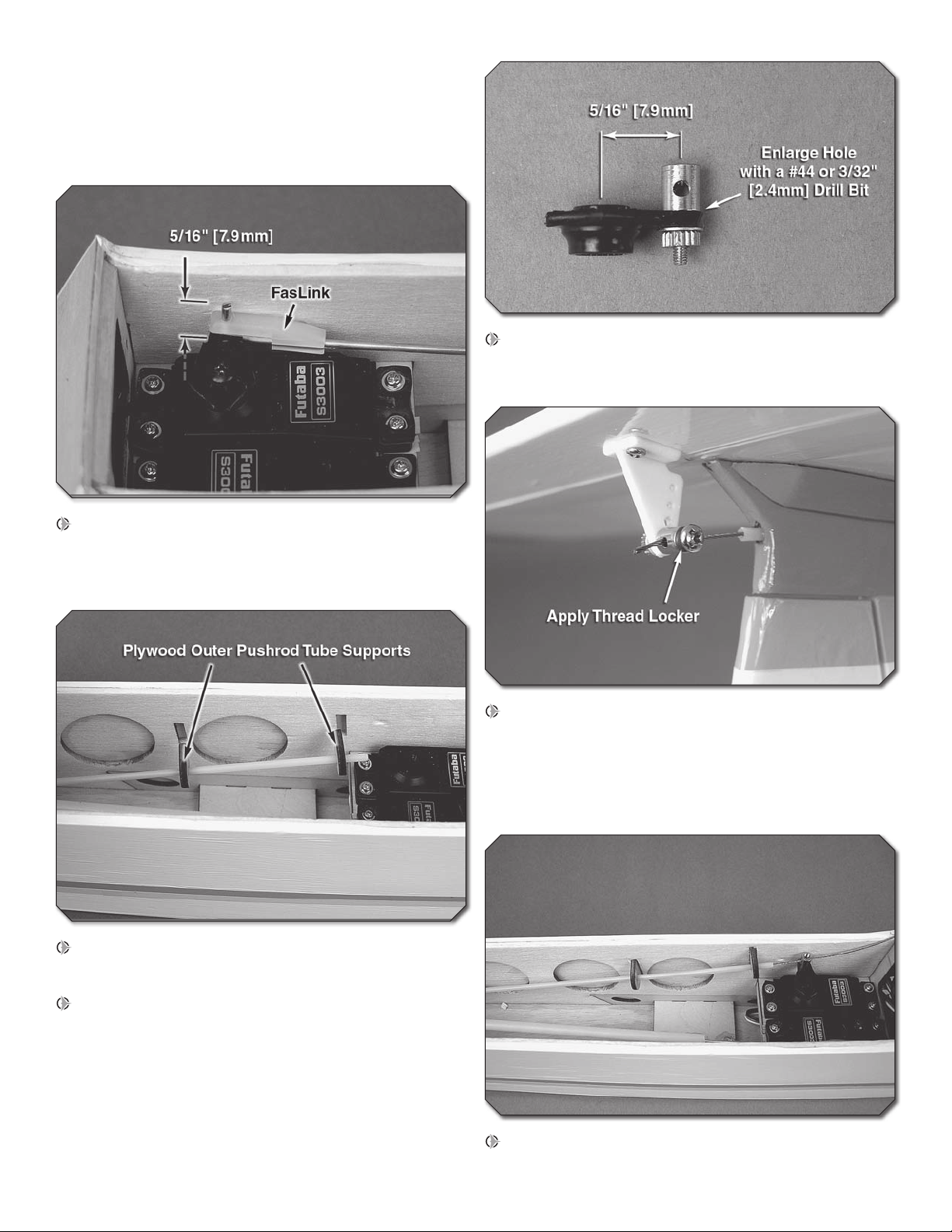

INSTALL THE RADIO SYSTEM ....................5

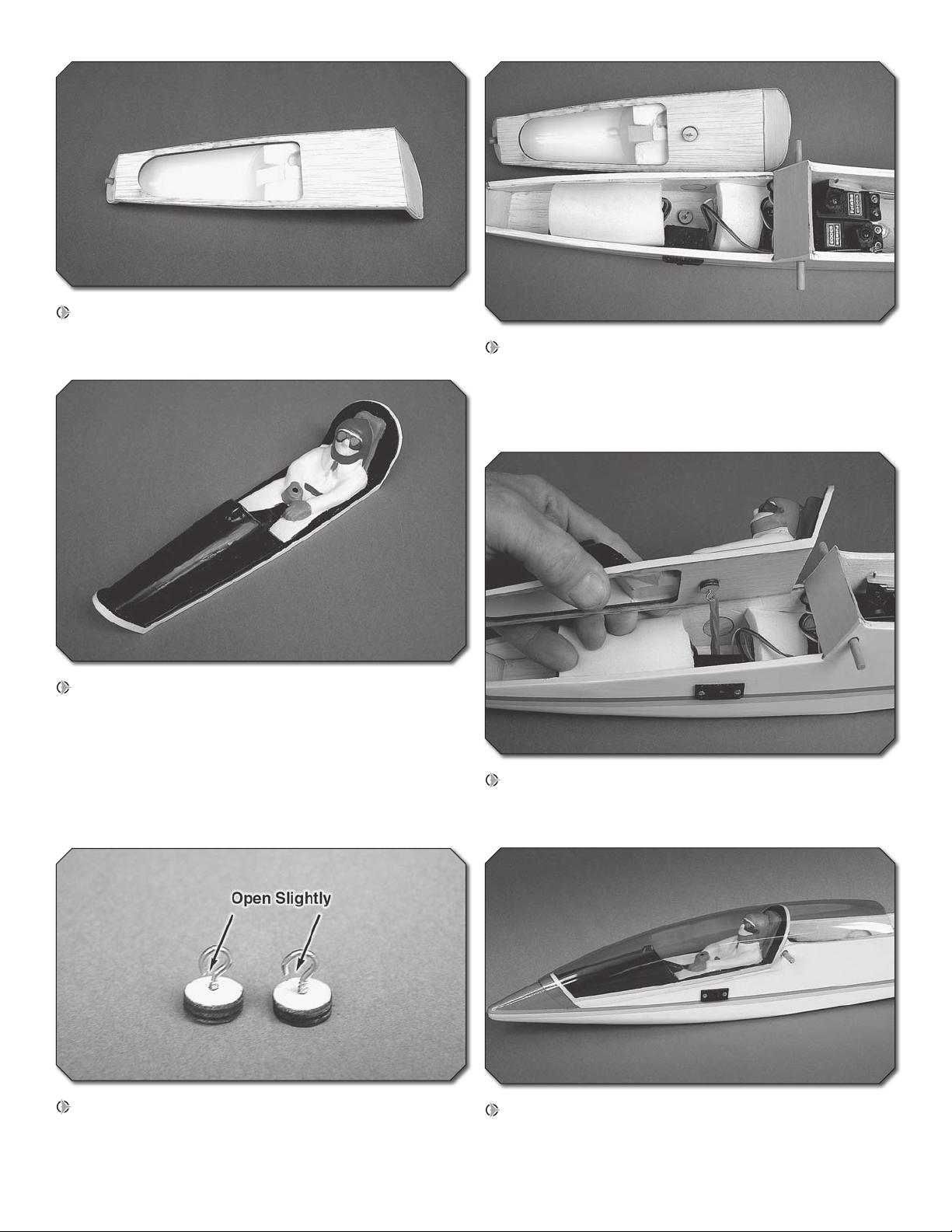

FINISH THE SAILPLANE..........................8

Canopy Installation.............................8

Apply the Decals .............................10

GET THE MODEL READY TO FLY .................11

Check the Control Directions . . . . . . . . . . . . . . . . . . . . 11

Set the Control Throws.........................11

Balance the Model (C.G.).......................12

Balance the Model Laterally.....................13

CHECKING FOR WARPS ........................13

PREFLIGHT ...................................13

Identify Your Model ............................13

Charge the Batteries ..........................13

Ground Check & Range Check ..................14

AMA SAFETY CODE............................14

General ....................................14

Radio Control ................................14

CHECK LIST ..................................14

FLYING.......................................15

Mount the Wing ..............................15

Trim Flights..................................15

Your First Hi-Start Launches ....................16

First Flights..................................16

Thermal Flying ...............................16

Facts About Thermals .........................16

Thermal Soaring .............................17

POINTERS FOR CONTEST FLYING................17

Ballasting ...................................18

ADDITIONAL ITEMS REQUIRED

RADIO EQUIPMENT

The Sophisticated Lady ARF requires a two-channel radio

system with standard size servos. The following servos are

recommended. A square receiver battery or a small flat

receiver battery is required to fit the narrow fuselage.

(2) Futaba®S-3003 Standard Servo (FUTM0031)

(1) HydriMax™1400mAh NiMH flat receiver battery

(HCAM6306)

HARDWARE AND ACCESSORIES

Following is additional hardware and accessories required

to finish the Sophisticated Lady ARF. Order numbers are

provided in parentheses.

1/4" Foam Rubber (GPMQ1000)

#64 Rubber Bands (HCAQ2020)

ADHESIVES AND BUILDING SUPPLIES

In addition to common household and hobby tools, this

is the “short list” of the most important items required to

assemble the Sophisticated Lady ARF. Great Planes Pro™

CA glue is recommended.

Thin CA (1/2 oz. [15g] Thin Pro CA, GPMR6001)

Medium CA (1/2 oz. [15g] Medium Pro CA+,

GPMR6007)

6-minute Pro Epoxy (4oz [113.4g] GPMR6042)

30-minute Pro Epoxy (4oz [113.4g] GPMR6043)

Mixing Sticks (GPMR8055)

Epoxy Brushes (GPMR8060)

Epoxy Mixing Cups (GPMR8056)

Paper Towels

Masking Tape

CA applicator tips (HCAR3780)

Threadlocker thread locking cement (GPMR6060)

#11 blades (5-pack, HCAR0211)

#1 Hobby knife (HCAR0105)

#44 or 3/32" [2.4mm] drill bit

Denatured Alcohol

Wax Paper

Needle-nose Pliers

OPTIONAL SUPPLIES AND TOOLS

Here is a list of optional tools mentioned in the manual that

will help you build the Sophisticated Lady ARF.

Stick–on segmented lead weight (GPMQ4485)

Hobby paints/paint brushes for painting the pilot

CA debonder (GPMR60390

CG Machine™(GPMR2400)

RC 56 Canopy Glue

High Start (DYFP8305)

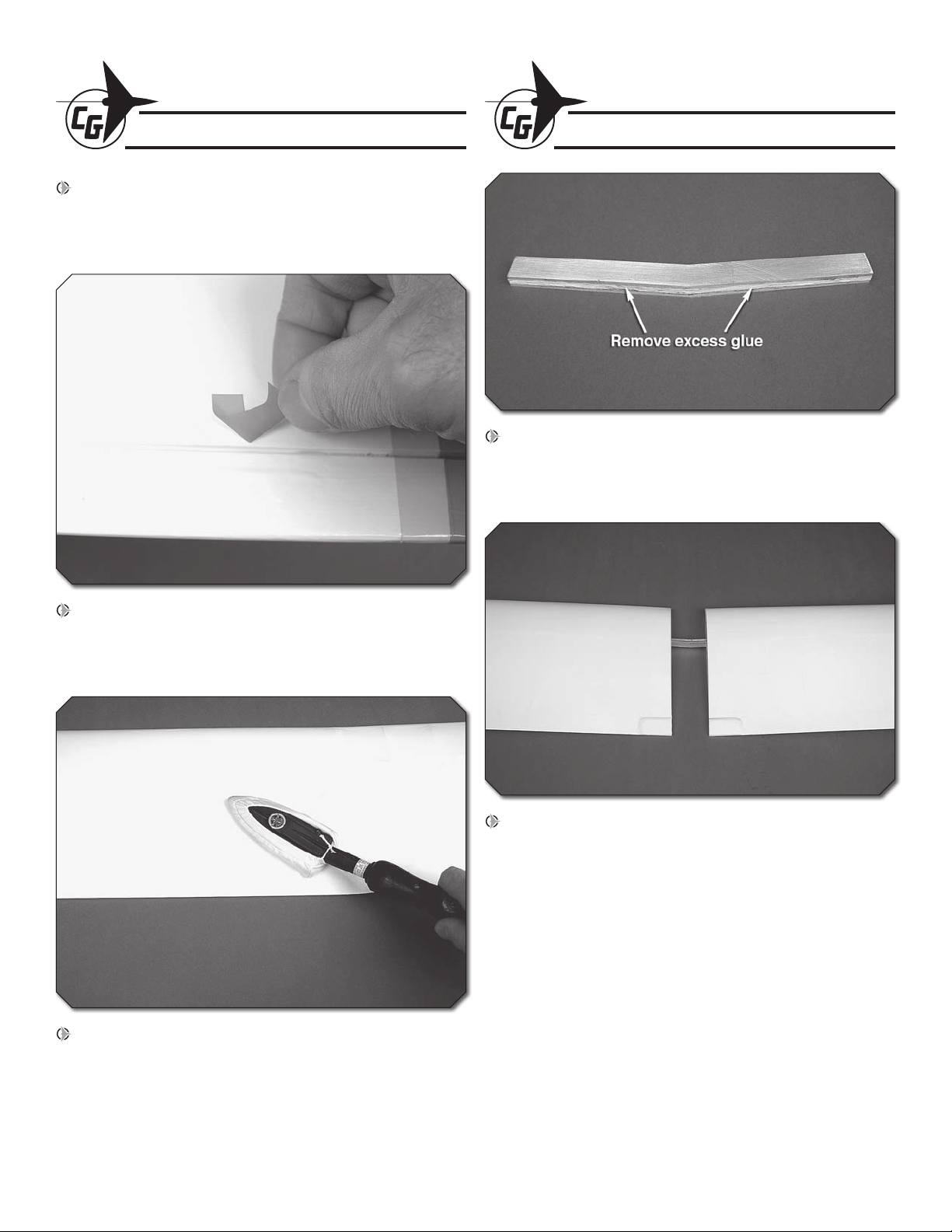

A model airplane covering iron with a protective covering

sock may also be necessary to retighten the covering

and remove any wrinkles that may have formed after the

model was originally covered at the factory. If you don’t

already have a covering iron, the 21st Century®sealing iron

(COVR2700) and the 21st Century iron cover (COVR2702)

are recommended.