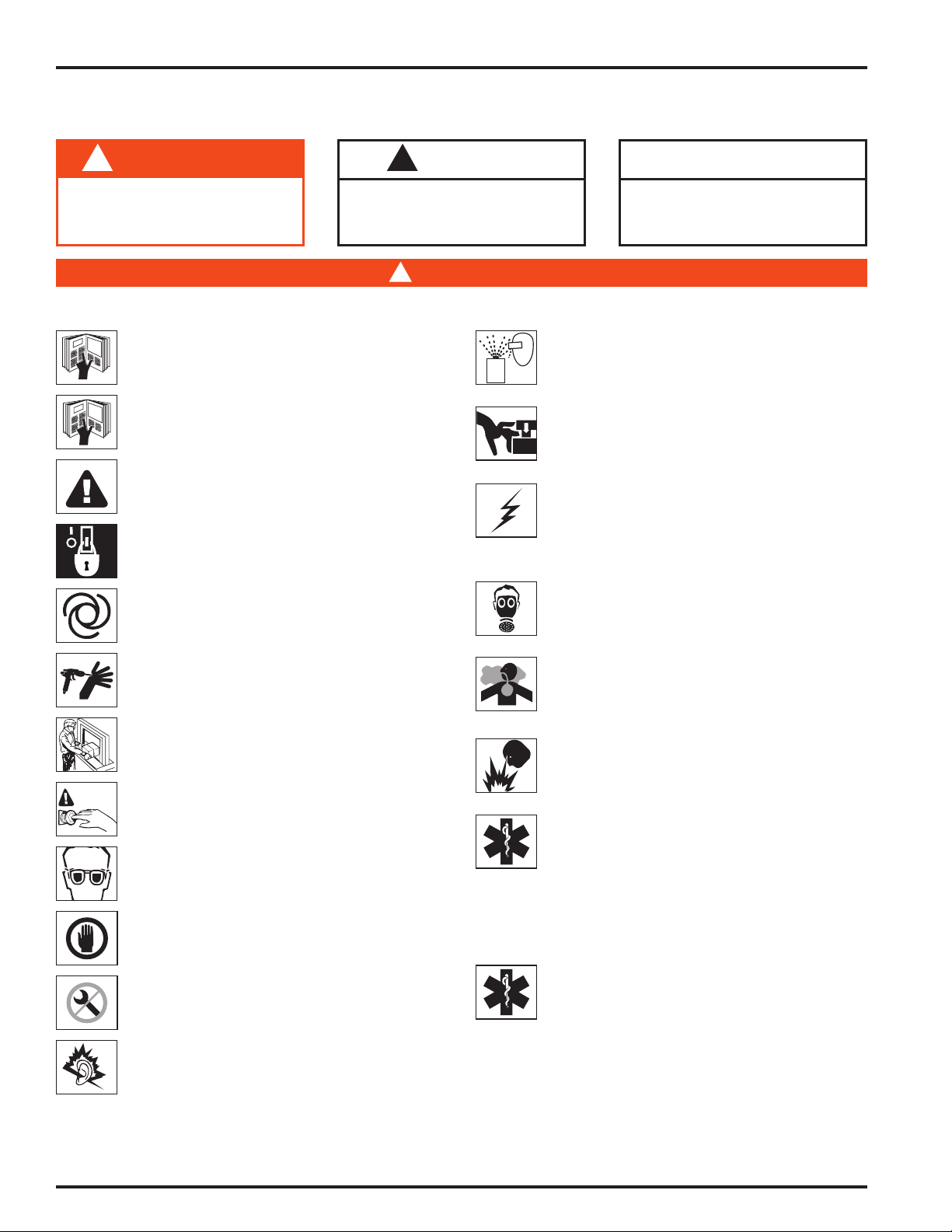

TRU-CURE UV-LED – SAFETY

To reduce risk of injury or property damage from UV

radiation, read, understand, and follow the following

safety instructions. In addition, make certain that

anyone else that uses this curing equipment follows

these safety instructions as well.

• Always wear eye protection. Failure to this may result in long

term injury to the eyes.

• Wear protective clothing. Hands, face and other parts of the

body shall not be exposed to heat and radiation. Do not stay

in front of the lamp cassettes during curing without safety

equipment.

• If a person works around UV radiation while on medications,

the medication should be checked to see if it would make the

person more photosensitive.

• Do not look directly at the light source.

• Professional commercial indoor use in a dedicated, isolated,

or restricted area, accessed only by qualied professional

operators.

• These products are intended only for use in a restricted

access area, or an area which incorporates suitable site

protection to prevent unintended exposure of untrained

or unqualied persons to ultraviolet radiation. It is the

responsibility of the designated parties at the nal installation

site to conrm that proper installation, training, and control

means have been implemented.

!

WARNING

READ ALL INSTRUCTIONS BEFORE USING “TRU-CURE UV LED”. WHEN USING ELECTRICAL EQUIPMENT,

BASIC PRECAUTIONS SHOULD ALWAYS BE FOLLOWED, INCLUDING THE FOLLOWING:

UV RADIATION

UV radiation can cause personal injury

and property damage! UV emitted from

this product. Skin or eye injury may oc-

cur. Avoid exposure of eyes and skin to

unshielded lamp.

Summary of results from RISE, Research Institutes of

Sweden AB:

Depending on the distance from the UV curing device, the

limit value according to AFS 2009:7 index b. (UVA eye) for

one working day (8 h) is reached after one or a few minutes

at close distances (0.5–1 m). At longer distances than about

5 m, the acceptable exposure time is an hour or more. The

acceptable exposure times according to index a. in AFS

2009:7 (UVA, UVB and UVC, skin and eye) are more than

50 times longer than for index b. (UVA eye).

!

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC

SHOCK OR INJURY:

• Do not allow to be used as a toy.

• Use only as described in this manual. Use only manufacturer’s

recommended attachments.

• Do not use the battery charger with damaged cord or plug.

If equipment is not working as it should, has been dropped,

damaged, left outdoors or dropped into water, return it to a

service center.

• Do not pull or carry the battery charger by cord, use cord

as a handle, close a door on cord or pull cord around sharp

edges or corners. Keep cord away from heated surfaces.

• Do not unplug the battery charger by pulling on cord. To

unplug, grasp the plug, not the cord.

• Do not handle plug or equipment with wet hands.

• Do not store, prepare or use solvent-containing materials

within a 5 m/16 feet radius of the curing device.

• Flammable materials should not be placed close to a curing

device in use.

• Never direct the curing device towards highly combustible

materials.

• The curing device must not be exposed to paint fog, sanding

dust or solvents due to re and explosion risk. Furthermore,

the lifetime of the appliance will also be reduced.

• The battery charger is operated by highly dangerous

electrical voltage.

• This product should only be used with the glass intact.

• As appropriate measures; always wear eye protection during

work in areas exposed to UV radiation and always work in a

well-ventilated environment.

• The curing device user must adhere to these operating

instructions. This appliance is not intended for use by persons

(including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of

the appliance by a person responsible for their safety.

• Do not use in wet or moisture conditions.

• Do not disassemble the battery.

• Use Tru-Cure UV-LED only with original battery.

• In damaged or leaking battery, dangerous vapors may occur.

Get fresh air. In case of inconvenience, get medical advice.

• Protect battery terminals against conductive subjects to

prevent short circuit.

• Protect battery from high temperature.

• Use the battery only with Tru-Cure UV-LED to prevent

overload.

• Do not allow children to replace batteries without adult

supervision.

• These products are intended to be operated only in the

presence of qualied professional operators who have been

trained on mandatory operation procedures for proper use of

the equipment.

!

WARNING

EN

SB-81-012-R1 (12/2022) 5 / 12 www.carlisleft.com