Page 1

®

MODELS

VCDD040C •VCDD050C • VCDD070C

!

CEILING/WALL-MOUNT

VENTILATORS

READ AND SAVETHESE INSTRUCTIONS

TABLE OF CONTENTS

This manual is divided into sections as follows:

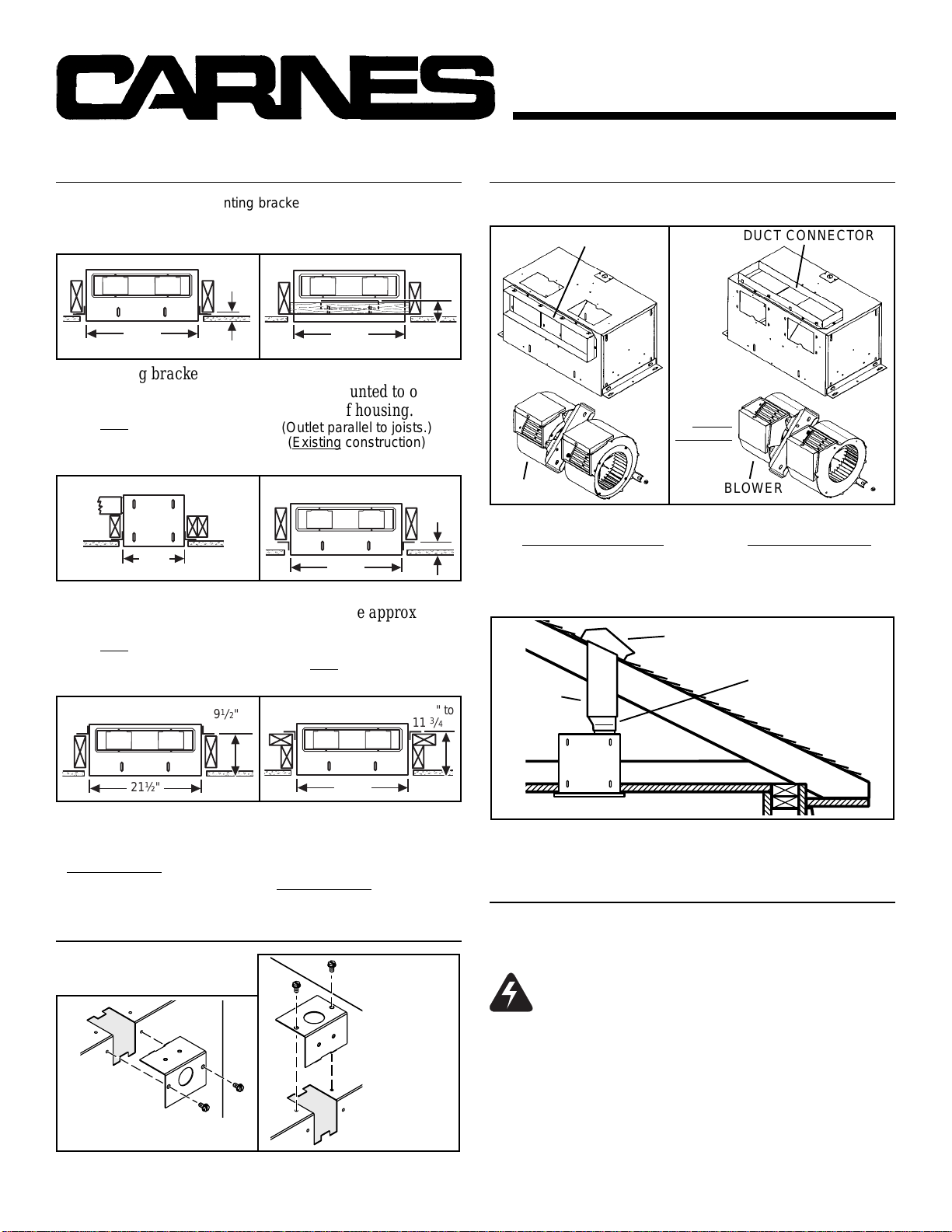

•“TYPICAL INSTALLATION”

This section shows a common installation in new and existing,

frame construction.

- Mounting (new construction)

- Mounting (existing construction)

- Wiring

- Ducting (horizontal blower discharge)

•“MOUNTING OPTIONS”

•“WIRING OPTIONS”

-Wiring Plate Position

•“DUCTING OPTIONS”

- Blower Discharge Positions

- Ducting (vertical blower discharge)

•“USE AND CARE”

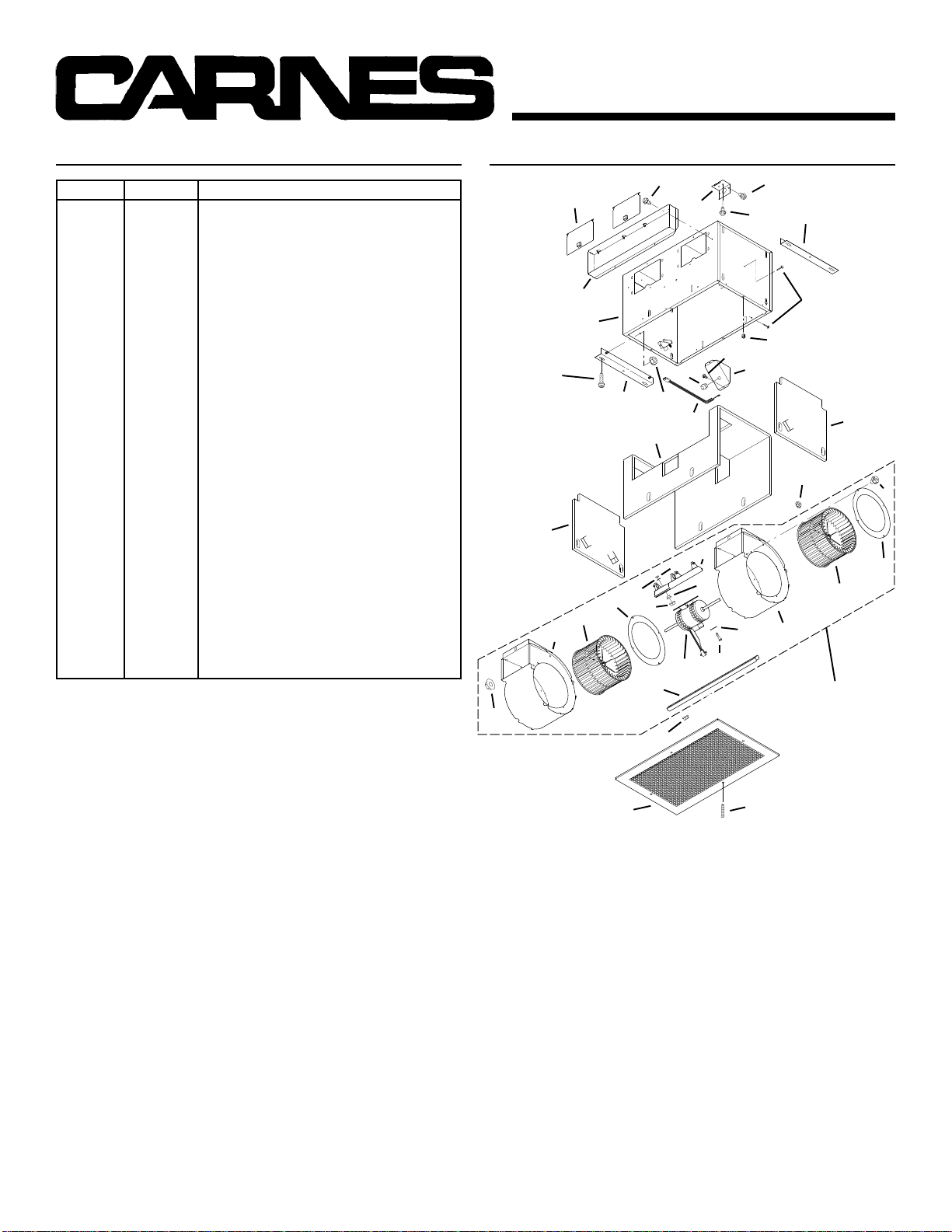

•“SERVICE PARTS”

•“WARRANTY”

Page 1

WARNING

TO REDUCE THE RISK OF FIRE,ELECTRIC SHOCK,OR IN-

JURYTO PERSONS,OBSERVETHE FOLLOWING:

1.Use this unit only in the manner intended by the manufacturer.If

you have questions, contact the manufacturer at the address or

telephone number listed in the warranty.

2.Beforeservicingorcleaningunit,switchpoweroffatservicepanel

andlock the servicedisconnectingmeansto prevent power from

being switched on accidentally.When the service disconnecting

means cannot be locked, securely fasten a prominent warning

device, such as a tag, to the service panel.

3.Installation work and electrical wiring must be done by a quali-

fied person(s) in accordance with all applicable codes and stan-

dards, including fire-rated construction codes and standards.

4.Sufficient air is needed for proper combustion and exhausting of

gases through the flue (chimney) of fuel burning equipment to

prevent backdrafting.Follow the heating equipment

manufacturer’s guideline and safety standards such as those

published by the National Fire Protection Association (NFPA),

andtheAmerican Society for Heating,Refrigeration andAir Con-

ditioning Engineers (ASHRAE), and the local code authorities.

5.When cutting or drilling into wall or ceiling, do not damage elec-

trical wiring and other hidden utilities.

6.Ducted fans must always be vented to the outdoors.

7.To reduce the risk of fire, use only metal ductwork.

8.If this unit is to be installed over a tub or shower, it must be

marked as appropriate for the application and be connected to a

GFCI (Ground Fault Interrupter) - protected branch circuit.

9.Never place a switch where it can be reached from a tub or

shower.

10.This unit must be grounded.

CAUTION

1.For general ventilating use only.Do not use to exhaust hazard-

ous or explosive materials and vapors.

2.To avoid motor bearing damage and noisy and/or unbalanced

impellers, keep drywall spray, construction dust, etc.off power

unit.

3.Please read specification label on product for further informa-

tion and requirements.