Carrier 50ZP036300 User manual

Other Carrier Air Conditioner manuals

Carrier

Carrier PGD4 Instruction Manual

Carrier

Carrier MOTORMASTER 48/50P3 User manual

Carrier

Carrier Modu-Pac 50DF034 Dimensions and installation guide

Carrier

Carrier 73KCA051D User manual

Carrier

Carrier 40GXC User manual

Carrier

Carrier SINGLE PACKAGED ELECTRIC COOLING UNITS 50GS Assembly Instructions

Carrier

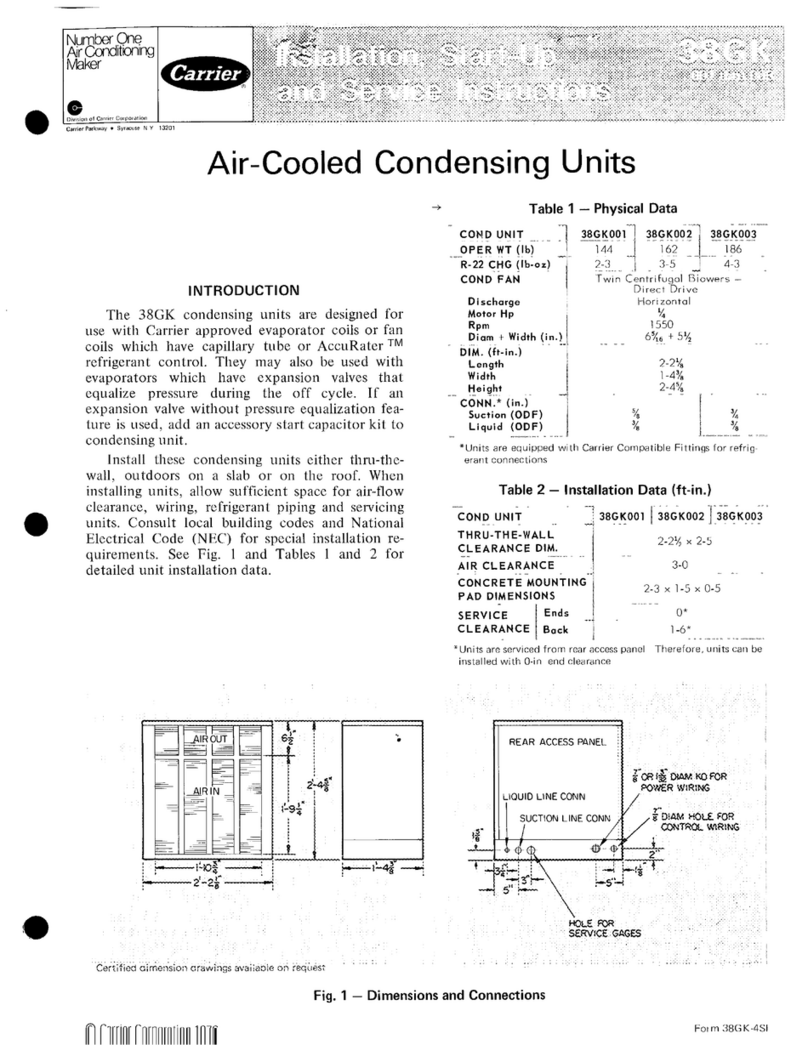

Carrier 38GK Dimensions and installation guide

Carrier

Carrier WeatherMaster 50HCQ 04 Series User manual

Carrier

Carrier WEATHERMASTER 50HJQ004 Dimensions and installation guide

Carrier

Carrier 42XPP050 User manual

Carrier

Carrier Gemini 38AU 16-28 Series Dimensions and installation guide

Carrier

Carrier 39CQ Manual

Carrier

Carrier 50GL 024-060 Assembly Instructions

Carrier

Carrier 42HQV025 User manual

Carrier

Carrier 38QHP09E8S series Repair manual

Carrier

Carrier Allegro 51AKE075 User manual

Carrier

Carrier LUVH025N User manual

Carrier

Carrier 42NQ009N User manual

Carrier

Carrier 42GCVBE010-703 User manual

Carrier

Carrier 50FC Series User manual

Popular Air Conditioner manuals by other brands

CIAT

CIAT Magister 2 Series Installation, Operation, Commissioning, Maintenance

Bestron

Bestron AAC6000 instruction manual

Frigidaire

Frigidaire FFRE0533S1E0 Use & care guide

Samsung

Samsung AS09HM3N user manual

Frigidaire

Frigidaire CRA073PU11 use & care

Soleus Air

Soleus Air GB-PAC-08E4 operating instructions