8Specifications subject to change without notice. CHS-072-121-01SI

INSTALLATION

Jobsite Survey

Complete the following checks before installation.

1. Consult local building codes and the NEC (National

Electrical Code) ANSI/NFPA 70 for special installa-

tion requirements.

2. Determine unit location (from project plans) or select

unit location.

3. Check for possible overhead obstructions which may

interfere with unit lifting or rigging.

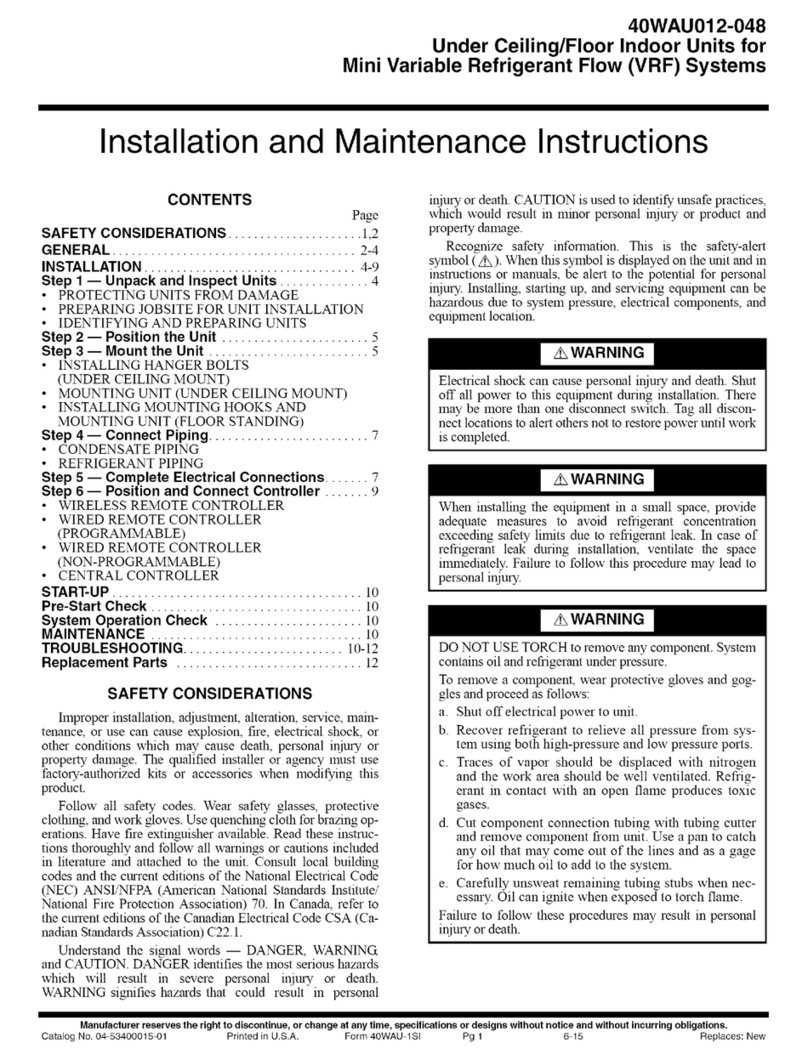

Step 1 — Plan for Unit Location

Select a location for the unit and its support system (pad, rails

or other) that provides for the minimum clearances required

for safety. This includes the clearance to combustible surfac-

es, unit performance and service access below, around and

above unit as specified in unit drawings. See Fig. 3.

Select a unit mounting system that provides adequate

height to allow for removal and disposal of frost and ice that

will form during the heating-defrost mode.

NOTE: Consider also the effect of adjacent units on airflow

performance and control box safety clearance.

Do not install the outdoor unit in an area where fresh air

supply to the outdoor coil may be restricted or when recircu-

lation from the condenser fan discharge is possible. Do not

locate the unit in a well or next to high walls.

Evaluate the path and required line length for interconnect-

ing refrigeration piping, including vapor riser requirements

and liquid line lift; a heat pump system will have one of each

type in opposite modes. Relocate sections to minimize the

length of interconnecting tubing.

Although unit is weatherproof, avoid locations that permit

water from higher level runoff and overhangs to fall onto the

unit.

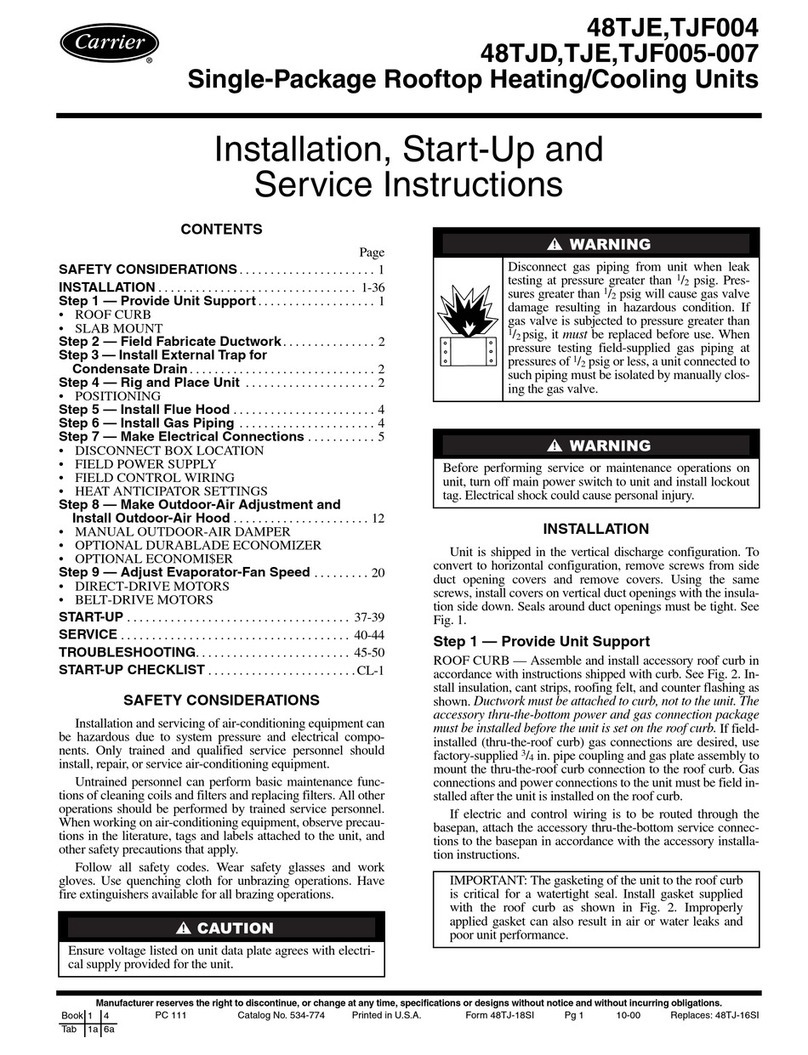

Fig. 3 — Service Clearance Dimensional Drawing

Step 2 — Complete Pre-Installation Checks

CHECK UNIT ELECTRIC CHARACTERISTIC

Confirm before installation of unit that voltage, amperage

and circuit protection requirements listed on unit data plate

agree with power supply provided.

UNCRATE UNIT

Remove unit packaging except for the top skid assembly,

which should be left in place until after the unit is rigged into

its final location.

INSPECT SHIPMENT

File a claim with shipping company if the shipment is dam-

aged or incomplete.

CONSIDER SYSTEM REQUIREMENTS

• Consult local building codes and National Electrical

Code (NEC, U.S.A.) for special installation require-

ments.

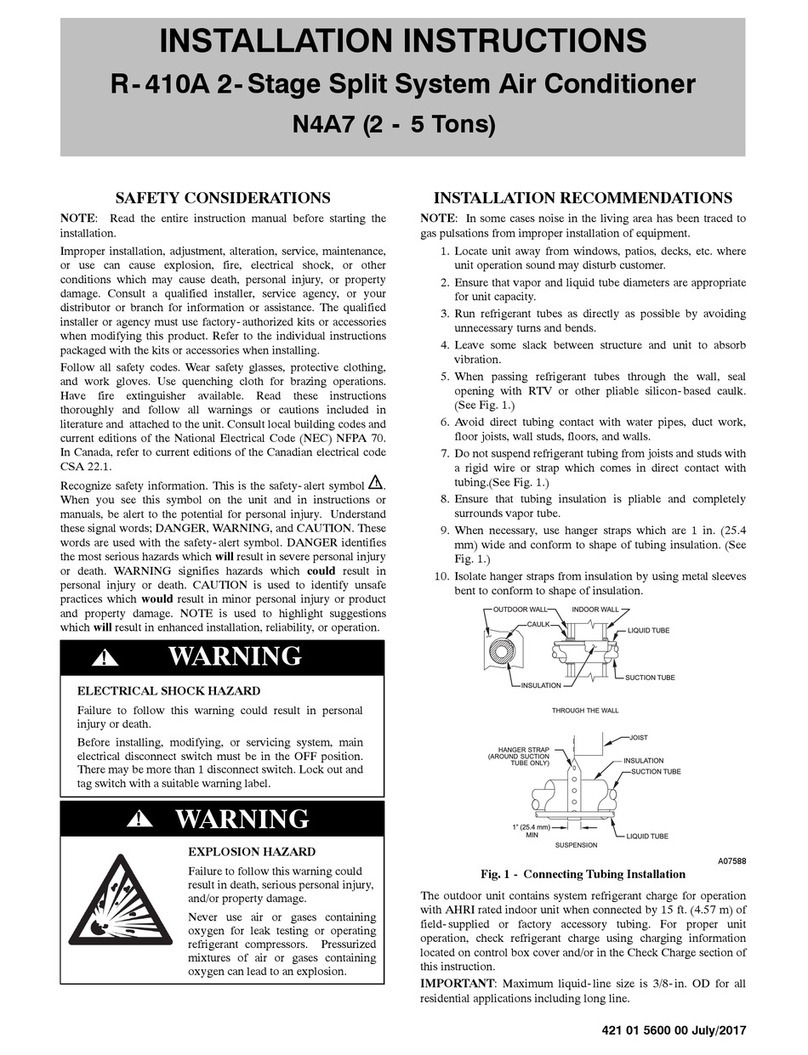

• Allow sufficient space for airflow clearance, wiring, re-

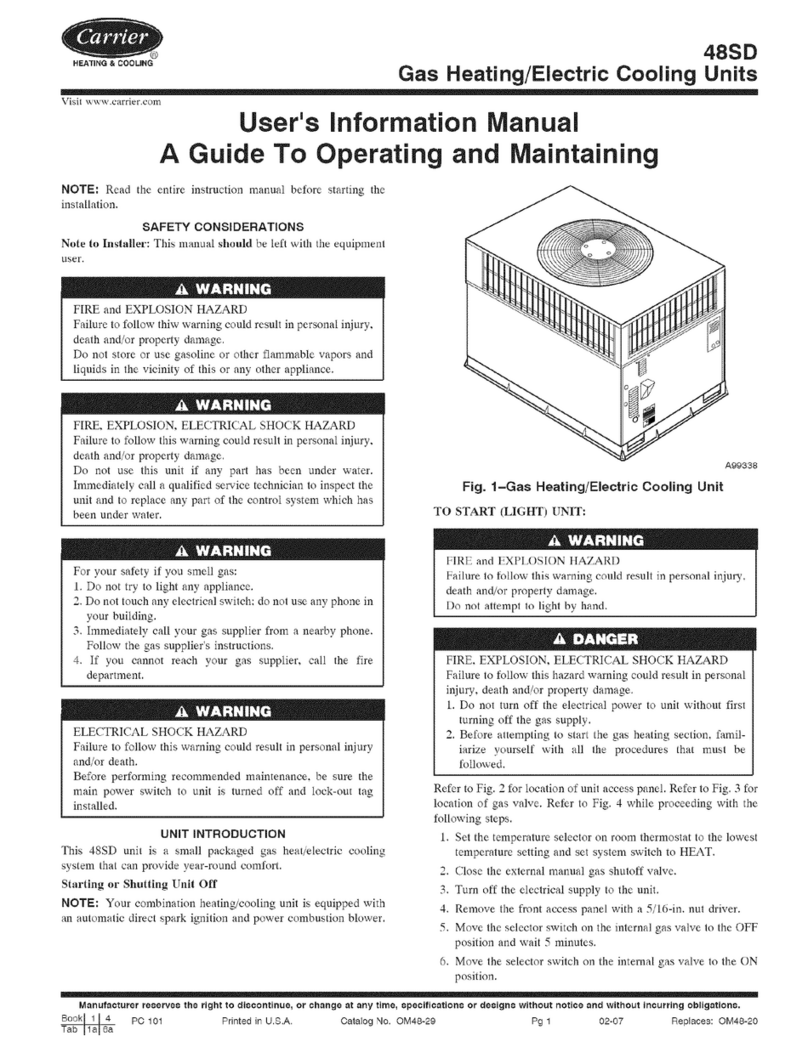

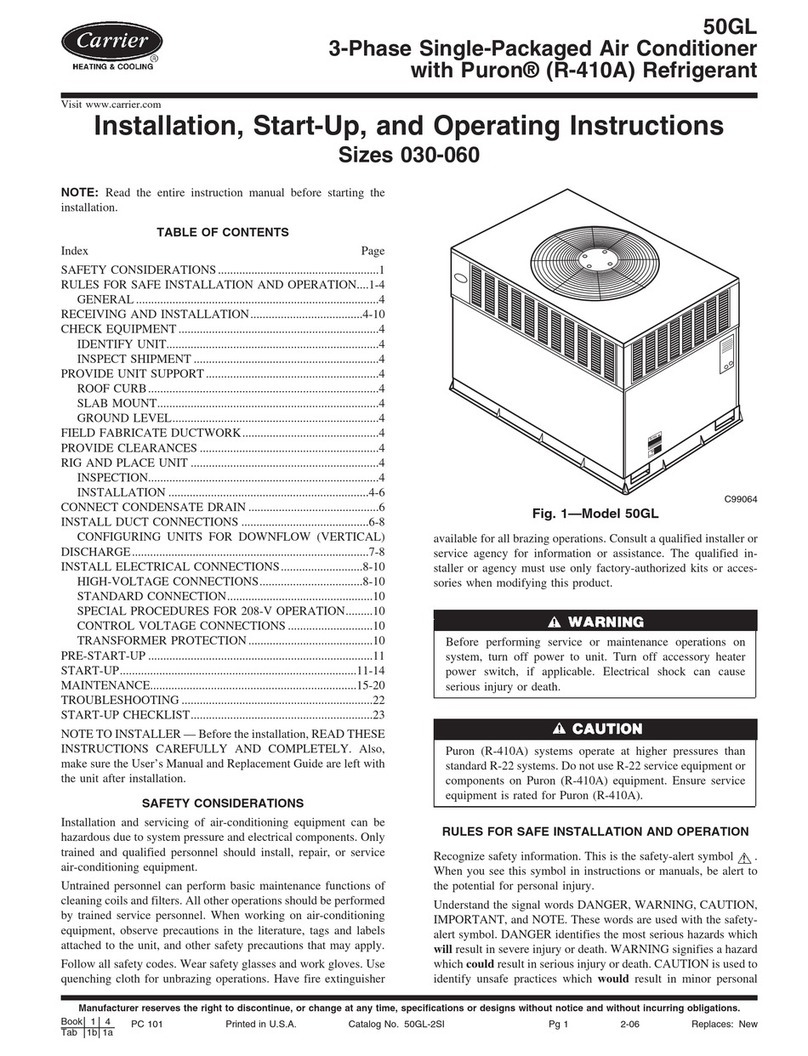

frigerant piping, and servicing unit. See Fig. 1 for unit

dimensions and weight distribution data.

• Locate the unit so that the outdoor coil (condenser)

airflow is unrestricted on all sides and above.

• The unit may be mounted on a level pad directly on

the base channels or mounted on raised pads at sup-

port points. See Tables 3 and 4 for unit operating

weights. See Fig. 1 for weight distribution based on

recommended support points.

NOTE: If vibration isolators are required for a particular

installation, use the data in Fig. 1 to make the proper

selection.

Step 3 — Prepare Unit Mounting Support

SLAB MOUNT

Provide a level concrete slab that extends a minimum of

6 in. (150 mm) beyond unit cabinet. Install a gravel apron in

front of condenser coil air inlet to prevent grass and foliage

from obstructing airflow.

Step 4 — Rig and Mount the Unit

RIGGING

These units are designed for overhead rigging. Refer to the

rigging label for preferred rigging method. Spreader bars are

not required if top crating is left on the unit. All panels must

be in place when rigging. As further protection for coil faces,

plywood sheets may be placed against the sides of the unit,

behind cables. Run cables to a central suspension point so

that the angle from the horizontal is not less than

45 degrees. Raise and set the unit down carefully.

If it is necessary to roll the unit into position, mount the unit

on longitudinal rails, using a minimum of 3 rollers. Apply

force to the rails, not the unit. If the unit is to be skidded into

position, place it on a large pad and drag it by the pad. Do

not apply any force to the unit.

Raise from above to lift the unit from the rails or pad when

unit is in its final position.

After the unit is in position, remove all shipping materials

and top crating.

Step 5 — Complete Refrigerant Piping

Connections

Refrigerant lines must be carefully designed and construct-

ed to ensure equipment reliability and efficiency. Line

length, pressure drop, compressor oil return, and vertical

separation are several of the design criteria that must be

evaluated. See Table 5.

IMPORTANT: DO NOT BURY REFRIGERATION LINES.

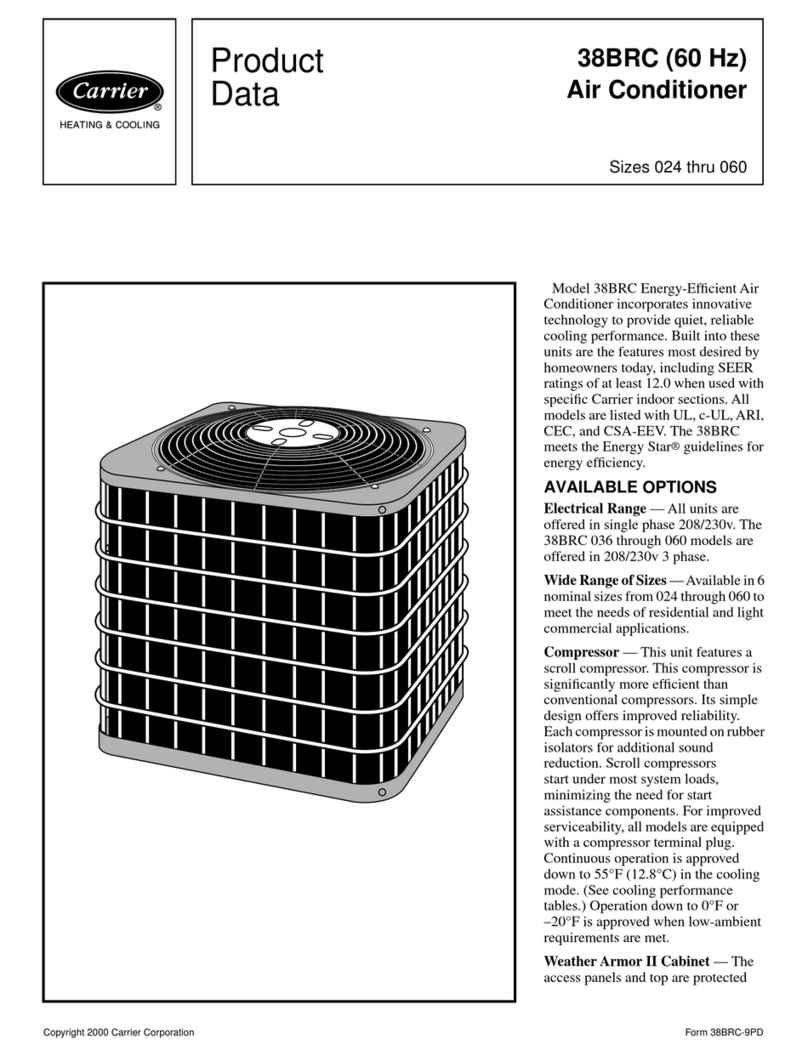

REAR:

Min 18" (457 mm)

required for service

RIGHT:

Min 18" (457 mm)

required for service

LEFT:

Min 18" (457 mm)

required for service

FRONT:

42” (1067 mm)

required for service

NOTE: Observe requirements for 39" (914 mm) operating

clearance on either Left or Rear coil opening.

IMPORTANT: Do not bury refrigerant piping underground.

IMPORTANT: A refrigerant receiver is not provided

with the unit. Do not install a receiver.