PGD4 Series K WPG4 Series K: Installation Instructions

Manufacturer reserves the right to change, at any time, specifications and designs without notice and without obligations.

3

removing outer horizontal flange.

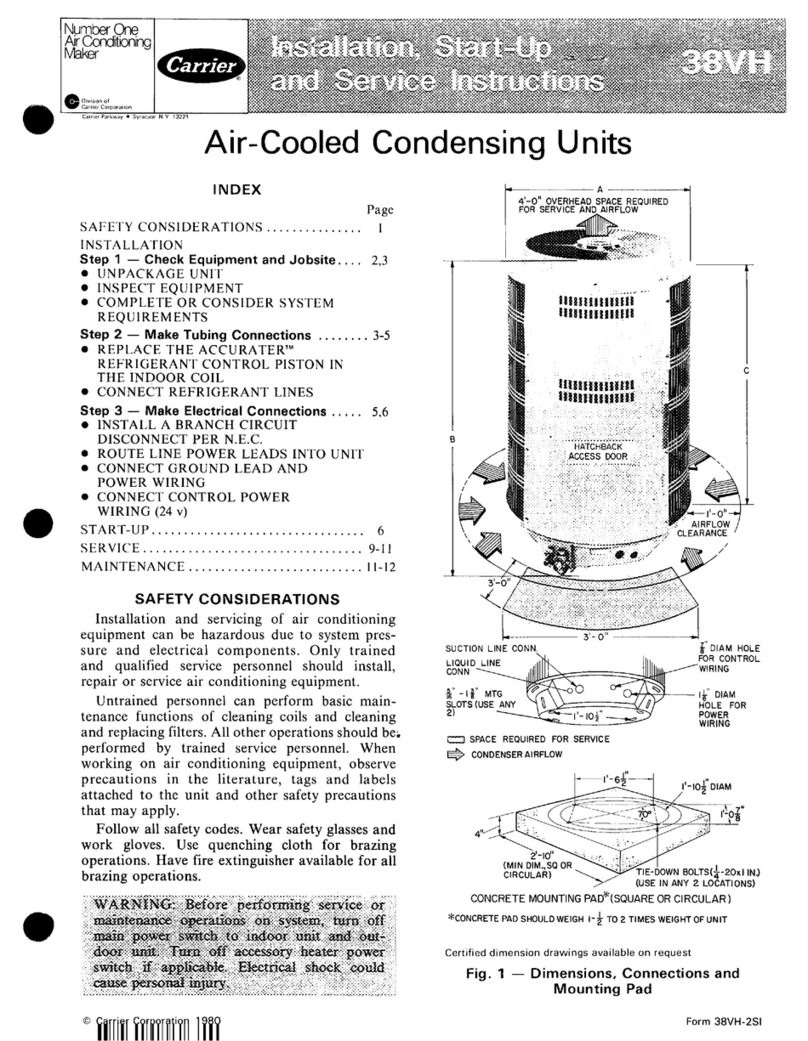

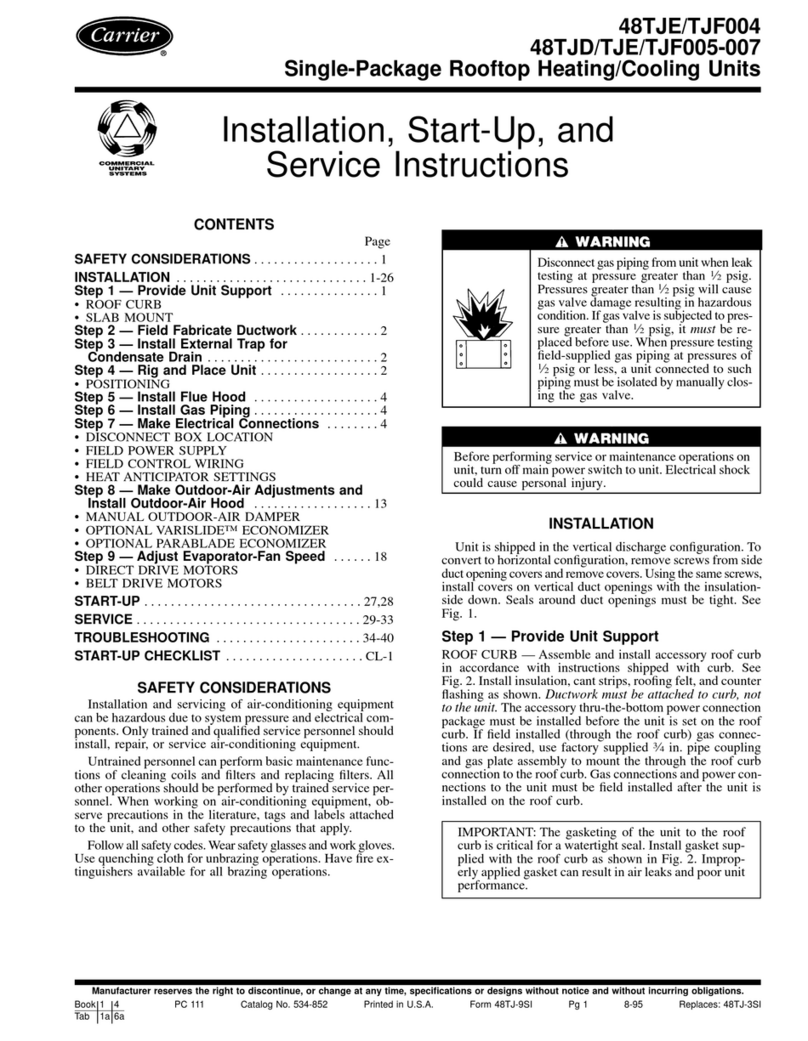

Slab Mount

Place the unit on a solid, level pad that is at least 2 in. (51 mm) above

grade. The pad should extend approximately 2 in. (51 mm) beyond the

casing on all 4 sides of the unit. (See Fig. 2.) Do not secure the unit to

the pad except when required by local codes.

A07926

Fig. 2 – Slab Mounting Details

Step 3 – Field Fabricate Ductwork

Secure all ducts to roof curb and building structure on vertical discharge

units. Do not connect ductwork to unit. For horizontal applications, unit

is provided with flanges on the horizontal openings. All ductwork should

be secured to the flanges. Insulate and weatherproof all external

ductwork, joints, and roof openings with counter flashing and mastic in

accordance with applicable codes.

Ducts passing through an unconditioned space must be insulated and

covered with a vapor barrier.

If a plenum return is used on a vertical unit, the return should be ducted

through the roof deck to comply with applicable fire codes.

Read unit rating plate for any required clearances around ductwork.

Cabinet return-air static shall not exceed -.25 IN. W.C.

Step 4 – Provide Clearances

IMPORTANT: The unit must be secured to the curb by installing

screws through the bottom of the curb flange and into the unit base rails.

When installing large base units onto the common curb, the screws must

be installed before allowing the full weight of the unit to rest on the curb.

A minimum of six screws are required for large base units. Failure to

secure unit properly could result in an unstable unit. See Warning near

Rigging/Lifting information and accessory curb instructions for more

details.

The required minimum operating and service clearances are shown in

Fig. 3 - Fig. 6. Adequate combustion, ventilation and condenser air must

be provided.

IMPORTANT: Do not restrict outdoor airflow. An air restriction at

either the outdoor-air inlet or the fan discharge may be detrimental to

compressor life.

The condenser fan pulls air through the condenser coil and discharges it

through the top grille. Be sure that the fan discharge does not recirculate

to the condenser coil. Do not locate the unit in either a corner or under an

overhead obstruction. The minimum clearance under a partial overhang

(such as a normal house overhang) is 48-in. (1219 mm) above the unit

top. The maximum horizontal extension of a partial overhang must not

exceed 48-in. (1219 mm).

Do not place the unit where water, ice, or snow from an overhang or roof

will damage or flood the unit. Do not install the unit on carpeting or

other combustible materials. Slab-mounted units should be at least 2 in.

(51 mm) above the highest expected water and runoff levels. Do not use

unit if it has been under water.

Step 5 – Rig and Place Unit

Rigging and handling of this equipment can be hazardous for many

reasons due to the installation location (roofs, elevated structures, etc.).

Only trained, qualified crane operators and ground support staff should

handle and install this equipment.

When working with this equipment, observe precautions in the literature,

on tags, stickers, and labels attached to the equipment, and any other

safety precautions that might apply.

Training for operators of the lifting equipment should include, but not be

limited to, the following:

1. Application of the lifter to the load, and adjustment of the lifts to

adapt to various sizes or kinds of loads.

2. Instruction in any special operation or precaution.

3. Condition of the load as it relates to operation of the lifting kit, such

as balance, temperature, etc.

Follow all applicable safety codes. Wear safety shoes and work gloves.

Inspection

Prior to initial use, and at monthly intervals, all rigging shackles, clevis

pins, and straps should be visually inspected for any damage, evidence

of wear, structural deformation, or cracks. Particular attention should be

paid to excessive wear at hoist hooking points and load support areas.

Materials showing any kind of wear in these areas must not be used and

should be discarded.

Rigging/Lifting of Unit (See Fig. 8)

CAUTION

!

UNITS/STRUCTURAL DAMAGE HAZARD

Failure to follow this caution may result in property damage.

Ensure there is sufficient clearance for saw blade when cutting the outer

horizontal flange of the roof curb so there is no damage to the roof or

flashing.

OPTIONAL

RETURN

AIR

OPENING

OPTIONAL

SUPPLY

AIR

OPENING

EVAP. COIL COND. COIL

ß

(50.8mm)

WARNING

!

PERSONAL INJURY OR PROPERTY DAMAGE

HAZARD

Failure to follow this warning could result in personal injury, death or

property damage.

When installing the unit on a rooftop, be sure the roof will support the

additional weight.

WARNING

!

PROPERTY DAMAGE HAZARD

Failure to follow this warning could result in personal injury/death or

property damage.

When straps are taut, the clevis should be a minimum of 36 in. (914

mm) above the unit top cover.

WARNING

!

UNIT FALLING HAZARD

Failure to follow this warning could result in personal injury or death.

Never stand beneath rigged units or lift over people.

WARNING

!

UNIT FALLING HAZARD

Failure to follow this warning could result in personal injury or death.

Large base units must be secured to common curb before allowing full

weight of unit to rest on curb. Install screws through curb into unit base

rails while rigging crane is still supporting unit.