Fan Shaft Bearings

Lubrication should only be done by qualified service personnel.

Contact your dealer for the required annual maintenance.

Evaporator and Condenser Coils

Cleaning of the coils should only be done by qualified service

personnel. This procedure should be performed prior to cooling

operation or more frequently should conditions require. Contact

your dealer for the required annual maintenance.

Condensate Drain

The drain pan and condensate drain line should be checked and

cleaned at the same time the cooling coils are checked by your

dealer.

Compressors

All compressors are factory shipped with a normal charge of the

correct type refrigerant grade oil in then] and should rarely require

additional oil. Unless the refrigerant system has been opened or a

compressor is replaced, there will not be a need to verify oil level.

Condenser Fan

PERSONAL INJURY HAZARD

Failure to follow this warning could result in personal iniury

or death.

Do not poke sticks, screwdrivers, or other object into

revolving fan blades.

The fan nmst be kept free of all obstructions to ensure proper

cooling. Contact your dealer for any required service,

Electrical Controls and Wiring

Electrical controls are difficult to check without proper

instrumentation; therefore, if there are any discrepancies in the

operating cycle, contact your dealer and request service.

Integrated Gas Controller (IGC)

The IGC board incorporates an LED that emits a flashing light to

indicate an alarm code. If the furnace section will not operate and

the LED is flashing a code (1 to 9 flashes in succession), contact

your dealer and request service. (See Fig. 1.) Removing power to

the unit will erase the IGC fault codes.

Refrigerant Circuits

The refrigerant circuits are difficult to check for leaks without the

proper equipment; therefore, if inadequate cooling is suspected,

contact your dealer for service.

Combustion Area and Vent System

The combustion area and vent system should be visually inspected

before each heating season. The normal accumulation of dirt, soot,

rust, and scale can result in loss of efficiency and improper

3erformance if allowed to build up.

FIRE HAZARD

Failure to follow this warning could result in personal injury,

death, and/or property damage.

If your unit makes and especially loud noise when the main

burners are ignited, shut down the heating section and call

your dealer.

See Fig. 1 and proceed as follows to inspect the combustion area

and power-venting system of your unit.

1. Turn off electrical power (install disconnect tag) and gas

supply to your unit.

2. Remove burner compartment access panel.

3. Using a flashlight, carefully inspect the burner areas for dirt,

soot, or scale.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in damage to unit.

If dirt, soot, rust or scale accunmlations are found, call your

dealer and do not operate your heating section.

4. When you have completed your inspection, follow the

start-up procedures in this manual to restore your unit to

operation.

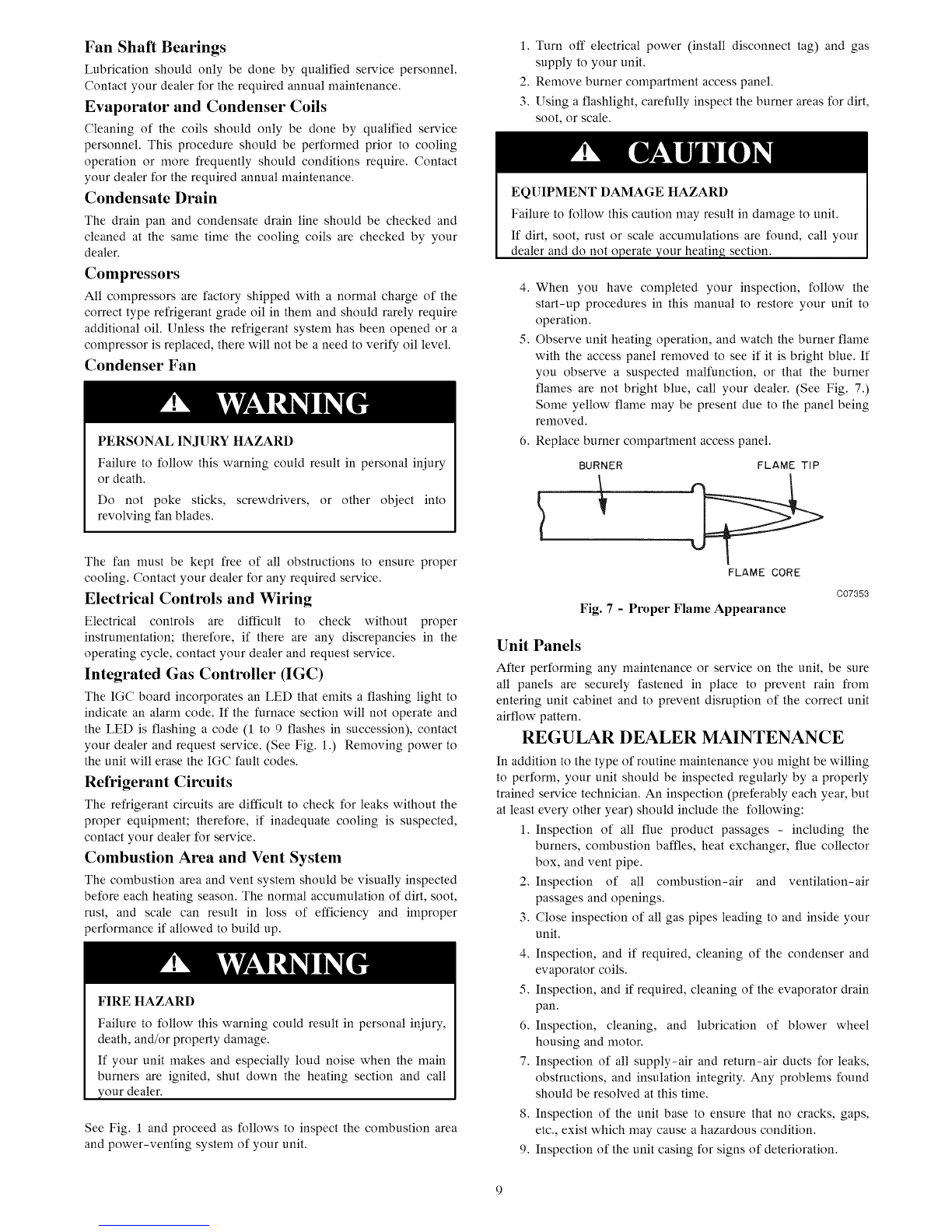

5. Observe unit heating operation, and watch the burner flame

with the access panel removed to see if it is bright blue. If

you observe a suspected malfunction, or that the burner

flames are not bright blue, call your dealer. (See Fig. 7.)

Some yellow flame may be present due to the panel being

removed.

6. Replace burner compartment access panel.

BURNER FLAME TIP

FLAME CORE

C07353

Fig. 7 -Proper Flame Appearance

Unit Panels

After perfornfing any maintenance or service on the unit, be sure

all panels are securely fastened in place to prevent rain from

entering unit cabinet and to prevent disruption of the correct unit

airflow pattern.

REGULAR DEALER MAINTENANCE

In addition to the type of routine maintenance you nfight be willing

to perform, your unit should be inspected regularly by a properly

trained service technician. An inspection (preferably each year, but

at least every other year) should include the following:

1. Inspection of all flue product passages - including the

burners, combustion baffles, heat exchanger, flue collector

box, and vent pipe.

2. Inspection of all combustion-air and ventilation-air

passages and openings.

3. Close inspection of all gas pipes leading to and inside your

unit.

4. Inspection, and if required, cleaning of the condenser and

evaporator coils.

5. Inspection, and if required, cleaning of the evaporator drain

pan.

6. Inspection, cleaning, and lubrication of blower wheel

housing and motor.

7. Inspection of all supply-air and return-air ducts for leaks,

obstructions, and insulation integrity. Any problems found

should be resolved at this time.

8. Inspection of the unit base to ensure that no cracks, gaps,

etc., exist which may cause a hazardous condition.

9. Inspection of the unit casing for signs of deterioration.