38YCA/YCN

Heat Pump

Installation and Start-Up Instructions

NOTE: Read the entire instruction manual before starting the

installation. Refer to Split-System Heat Pump Installation and

Start-Up Instructions (included in this packet).

SAFETY CONSIDERATIONS

Improper installation, adjustment, alteration, service, maintenance,

or use can cause explosion, fire, electrical shock, or other

conditions which may cause personal injury or property damage.

Consult a qualified installer, service agency, or your distributor or

branch for information or assistance. The qualified installer or

agency must use factory-authorized kits or accessories when

modifying this product. Refer to the individual instructions pack-

aged with the kits or accessories when installing.

Follow all safety codes. Wear safety glasses and work gloves. Use

quenching cloth for brazing operations. Have fire extinguisher

available. Read these instructions thoroughly and follow all

warnings or cautions attached to the unit. Consult local building

codes and the National Electrical Code (NEC) for special instal-

lation requirements.

Recognize safety information. This is the safety-alert symbol .

When you see this symbol on the unit or in instructions and

manuals, be alert to the potential for personal injury.

Understand the signal word DANGER, WARNING, or CAU-

TION. These words are used with the safety-alert symbol. DAN-

GER identifies the most serious hazards which will result in severe

personal injury or death. WARNING signifies hazards that could

result in personal injury or death. CAUTION is used to identify

unsafe practices which would result in minor personal injury or

product and property damage.

Before installing or servicing system, always turn off main

power to system. There may be more than 1 disconnect

switch. Turn off accessory heater power if applicable. Elec-

trical shock can cause personal injury or death.

INSTALLATION

Step 1—Mounting Pad

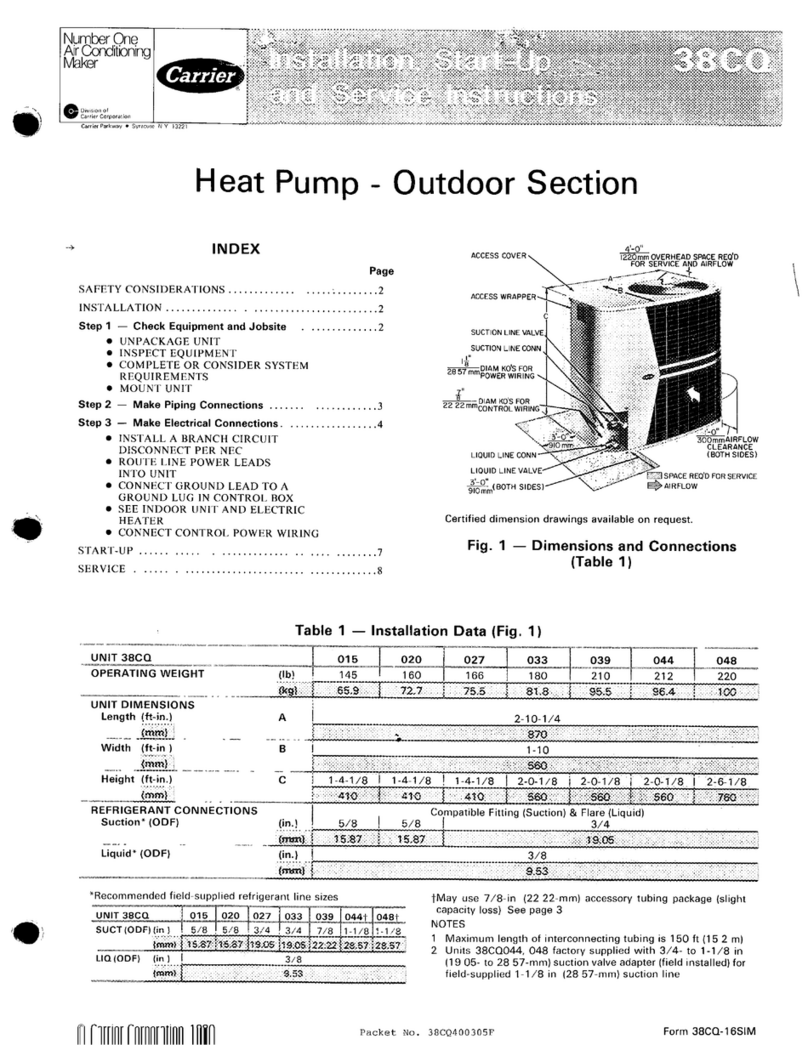

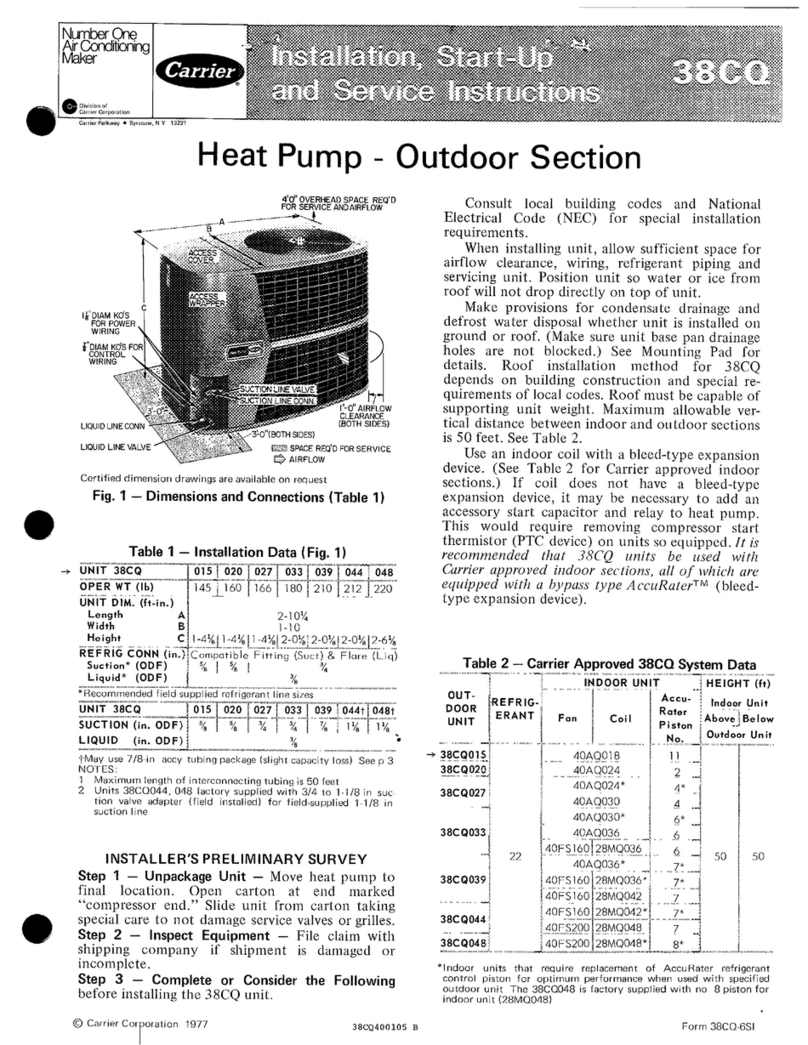

Refer to Table 1 for mounting pad dimensions.

Step 2—Refrigerant Tubing

Refer to Table 2 for proper refrigerant tube diameters.

Step 3—Mechanical Connection (38YCN Model)

1. Remove plastic retainer holding outdoor piston and piston

retainer in the liquid service valve. Connect and tighten the

liquid service valve adapter to the valve body prior to

assembling ferrule/lock nut. (See Fig. 2.)

2. Cut tubing to the correct length, deburr and size as necessary,

making sure tube ends are square. If a large burr is evident, the

ID and OD must be deburred to allow the tube to bottom in

valve.

3. Remove lock nut and ferrule from plastic bag taped to service

panel. (See Fig. 3.) Remove the lock nut and ferrule from

liquid service valve adapter. (See Fig. 2.)

If undersized, damaged, or elliptically shaped tubing is used

when making connection, leaks could result.

4. Slide the lock nut and ferrule onto each tube. (See Fig. 4.)

5. Apply a few drops of refrigerant oil to the ferrule and valve

threads and adapter threads to reduce assembly torque and

assist sealing.

6. Insert tube end into the service valve or adapter until it

bottoms.

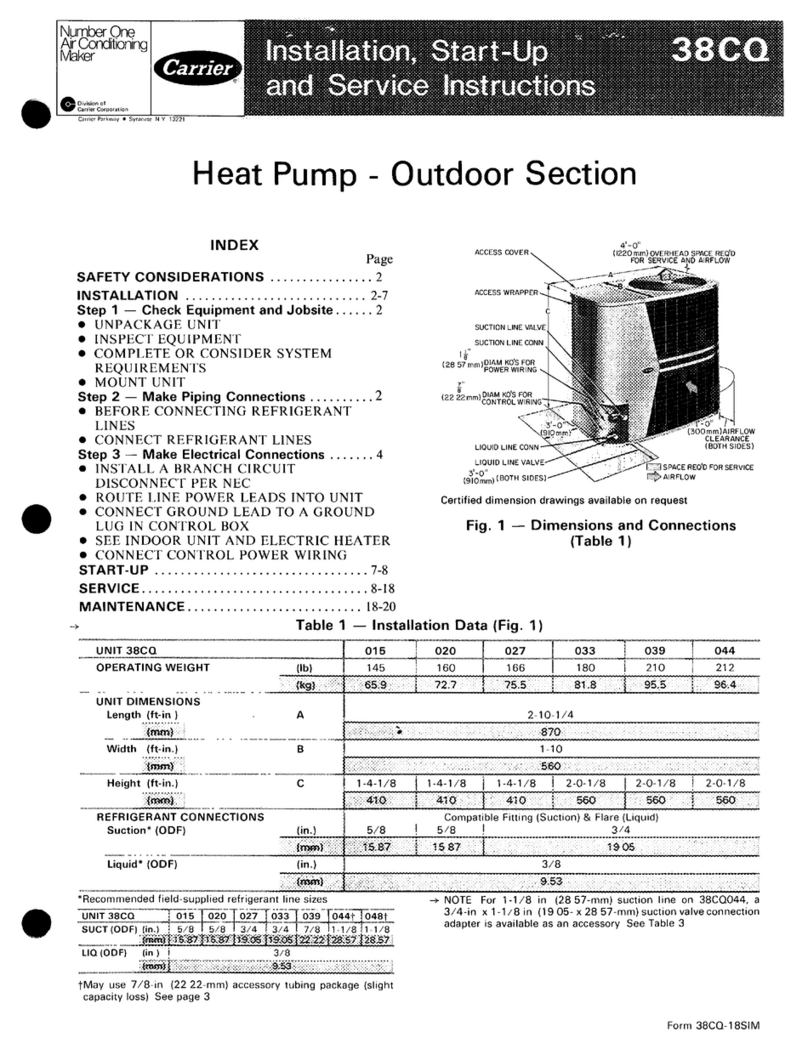

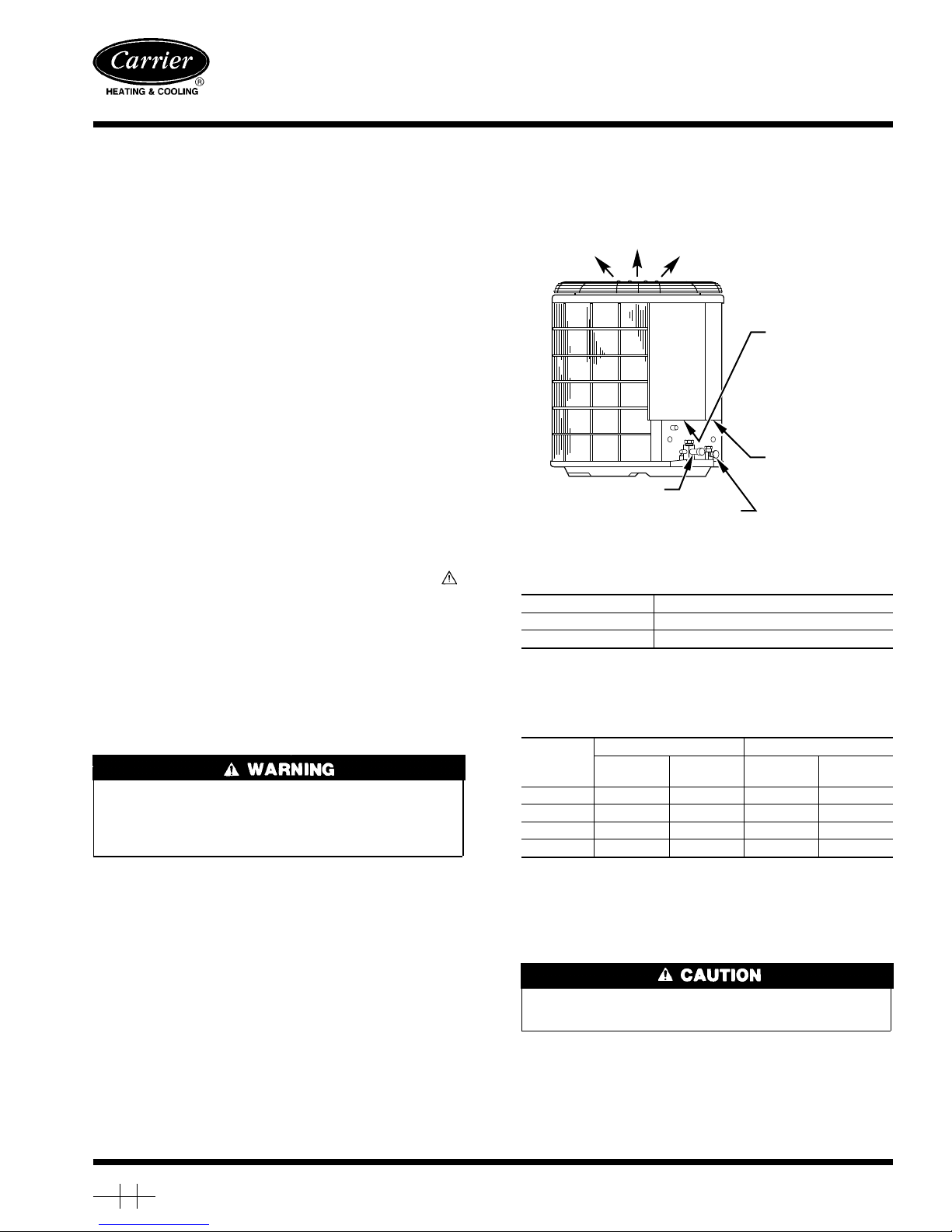

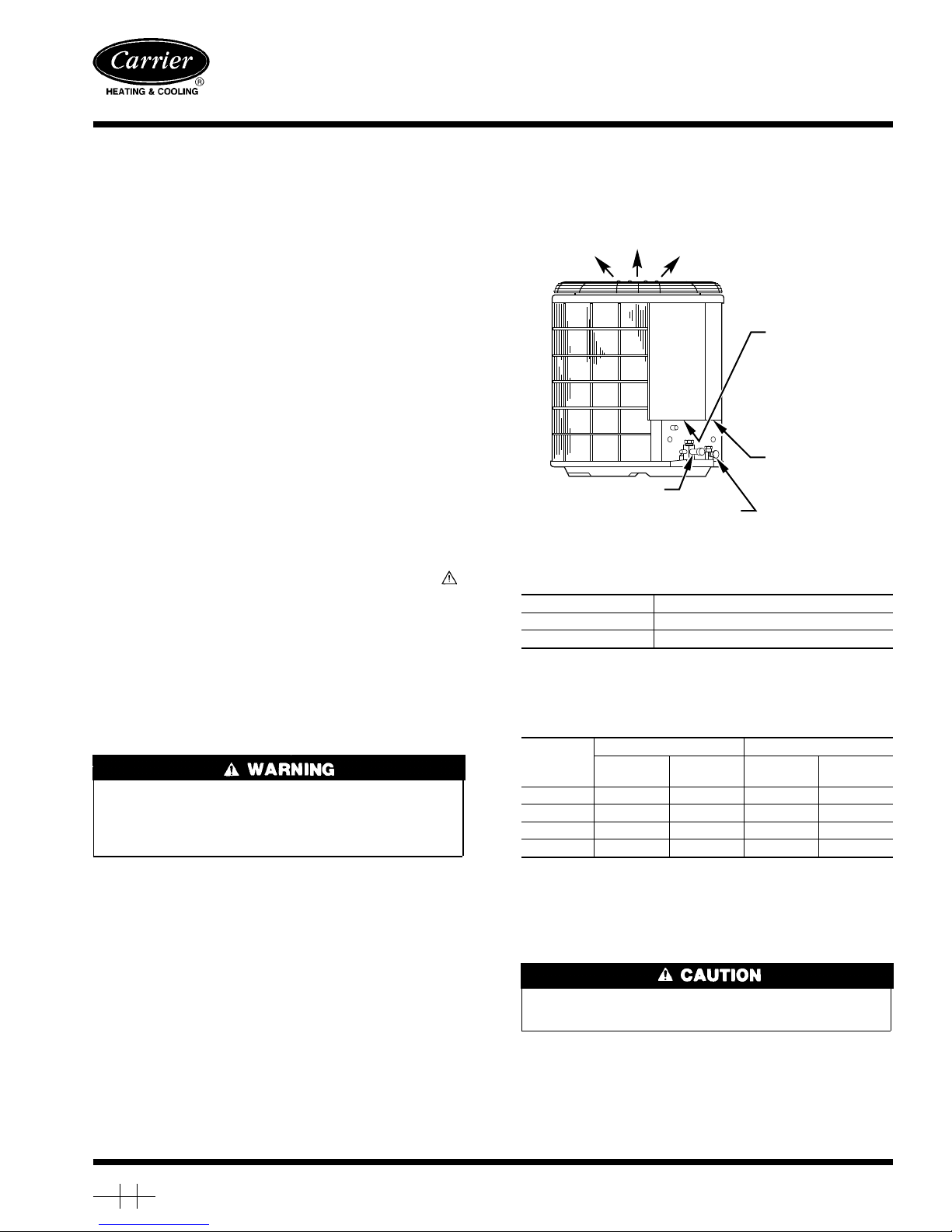

Fig. 1—Unit Connections A93578

LIQUID LINE CONN

FIELD CONTROL

SUPPLY CONN

7⁄8″ DIA HOLE

FIELD POWER

SUPPLY CONN

7⁄8″ DIA HOLE WITH

1 1⁄8″ DIA KNOCKOUT

AND 1 3⁄8″ DIA

KNOCKOUT

AIR DISCHARGE

SUCTION LINE CONN

Table 1—Mounting Pad Dimensions

UNIT SIZE MINIMUM DIMENSIONS (IN.)

018-030 22-1/2 x 22-1/2

036-060 30 x 30

Table 2—Refrigerant Connections and

Recommended Liquid and Vapor Tube Diameters

(In.)

UNIT

SIZE

LIQUID VAPOR

Connect

Diameter Tube

Diameter Connect

Diameter Tube

Diameter

018, 024 3/8 3/8 5/8 5/8

030, 036 3/8 3/8 3/4 3/4

042, 048 3/8 3/8 7/8 7/8

060 3/8 3/8 7/8 1-1/8

Note: Tube diameters are for lengths up to 50 ft. For tubing lengths greater

than 50 ft, consult your local distributor.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Book 1 4

Tab 5a 5a PC 101 Catalog No. 563-733 Printed in U.S.A. Form 38YCA-3SI Pg 1 2-94 Replaces: 38YCA-2SI