to remove the ice fi'om the unit grille. This condition will not affect

the proper function of the uriit and will clear within a few days.

Step g--Emergency Heat Mode

This allows your supplemental heating source to keep your home

or office wam_ until your heat pump can be sela'iced.

mNPORTANT FACTS

To better protect your investment and to eliminate nnnecessaD"

service calls, fim_iliarize yourself with the following ii_cts:

During heating, increasing the tlaermostat setting more than 2c_may

cause the supplemental heaters to be turned on fbr a short period

of time to satisfy the thermostat. Needles use of the supplementary

heat reduces potential energy savings.

Ice or f?ost will tend to form on the coil during the winter heating

operation. Your heat pump is designed to automatically melt the

ice. When in this defrost cycle, it is not_nai for steam or fog to rise

fi'om the outdoor unit. Do not be alarmed!

ROUTINE NAINTENANCE

All routine maintenance should be handled by skilled, experiericed

personnel. Your dealer can help you establish a standard proceo

dure.

For your sat'cty, keep the unit area clear and fi'ee of combustible

materials, gasoline, and other flammable liquids and vapors.

To assure proper functioning of the unit, flow of condenser air

must not be obstr_/cted from reaching the unit. Clearance from the

top of the unit is 48 in. Clearance of at least 36 in. is required on

sides except the power entry side (42 in. clearance) and the duct

side (12 in. rain clearance).

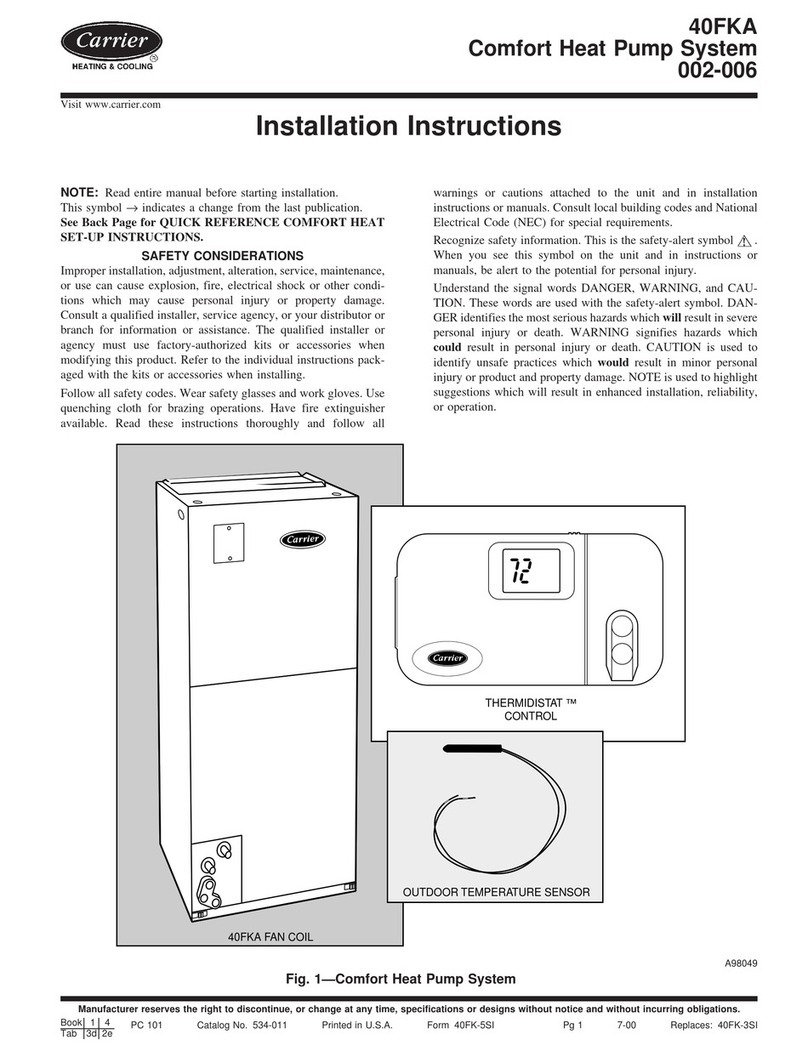

FILTER ACCESS

PANEL*

Fig.

ACCESS PANEL

*For accessory filter rack.

2--FHter Access Panel--VerticN Supply

Shown

Table 1 -- Indoor-Air Fitter Data

UNIT SIZE FILTER SIZE

50JZ024-030 20x20x1

50JZ036 20x24xl

50JZ042o060 24x30x1

NA_NTENANCE AND CARE FOR THE EQUmPNENT

OWNER

Befbre proceeding with those things yon might want to maintain

yourself; please carefldly consider the following:

1. TURN OFF ELE(TRICAL POWER TO YOUR UNIT

BEFORE SERVI(ING OR PERFORMING MAINTE-

NAN(E. ELE(TRIC SHO(K COULD (AUSE SERI-

OUS INJURY OR DEATH.

2. When removing access panels or perfbm_ing maintenance

Nnctions inside your unit, be aware of sharp sheet metal

parts and screws. Although special care is taken to reduce

sharp edges to a minimum, be extremely careNl when

handling parts or reaching into the unit.

AIR FILTERS Air filters should be checked at least every 3 or

4 weeks arid changed or cleaned whenever it becomes dirty. Dirty

filters produce excessive stress on the blower motor and can cause

the motor to overheat and shut down. Table 1 indicates the correct

filter size fbr your unit Refer to Fig 2to access the filters

To replace or inspect filters (or accessory- filter rack when

supplied):

1. Remove the filter access panel using a 5/16-in. nut driver.

2. Remove _he filters by pulling the filters out of the unit. If the

filters is dirty, clean or replace with new one.

When installing the new filters, note the direction of the airflow

arrows on the filter frame.

If you have difficulty" in locating your air filter(s), or if you have

questions concerning proper filter maintenance, contact your

dealer for instructions. When replacing filters, always use the same

size and type of filter that was supplied originally by the installer.

Never operate your unit without filters in place. Failure to

heed this warning may result in damage to the blower motor

and/or compressor An accumulation of dust arid lint on

internal parts of your unit can cause loss of efficiency and, in

SOITIe cases_ fire

FANS AND FAN MOTOR Periodically check d_e condition of

fan wheels and housings and fan-motor shaft bearings No lubrio

cation of outdoor- or indooroflm bearings or motors is required or

recommended

INDOOR AND OUTDOOR COILS Cleaning of the coils

should only be done by qualified service personnel. (ontact your

dealer fbr the required annual maintenance.

CONDENSATE DRAIN The drain pan and condensate &ain

line should be checked and cleaned at the same time the cooling

coils are checked by your dealer.

COMPRESSOR All compressors are fi_ctoryoshipped with a

normal charge of the correct type refi'igeration grade oil in them

and should rarely require additional oil.

CONDENSER FAN

Do not poke sticks, screwdrivers, or any other object into

revolving fan blades Injury or equipment damage may result

The fire mttst be kept flee of all obstructions to ensure proper

cooling Contact your dealer for any required service.

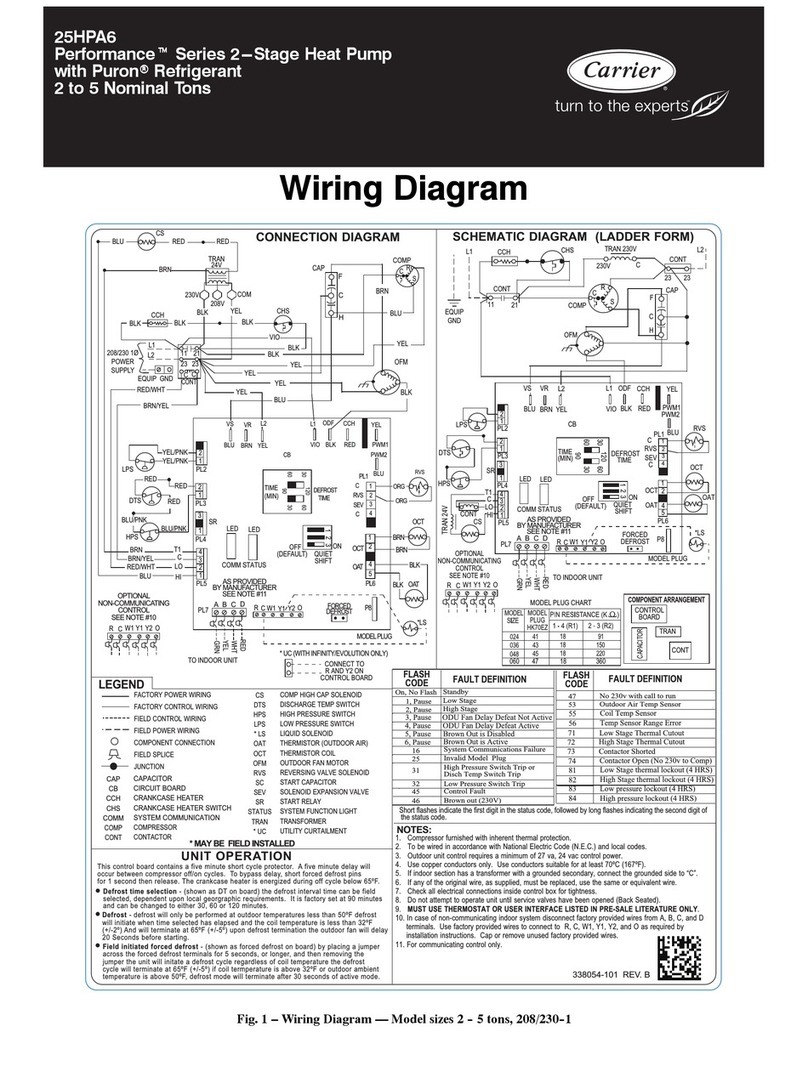

ELECTRICAL (ONTROLS AND WIRING Electrical con°

trois are difticult to check without proper instrumentations; there-

fore, if there are any discrepancies in the operating cycle, contact

your dealer and request sela'ice.