3.1 95-86005

CAMERA LOCATION

Cameras should be positioned to provide the best

unobstructed view of the area to be monitored. If the

camera is to monitor the same area as the detector,

it should be mounted as close to the detector as

practical. The following factors should also be taken into

consideration:

• Be sure that the unit is easily accessible for cleaning

and other periodic servicing.

• Care must be taken to ensure that dirt, moisture or

other contaminants will not accumulate on the lens

and obscure the vision of the camera. If possible,

point the camera slightly downward.

• The camera should be mounted on a rigid surface in

a low vibration area.

• The camera should not be placed where rising

combustion products can obscure its vision. If

dense smoke is expected to accumulate at the onset

of a fire, the camera should be mounted on a side

wall at least a few feet (approximately 1 meter) down

from the ceiling.

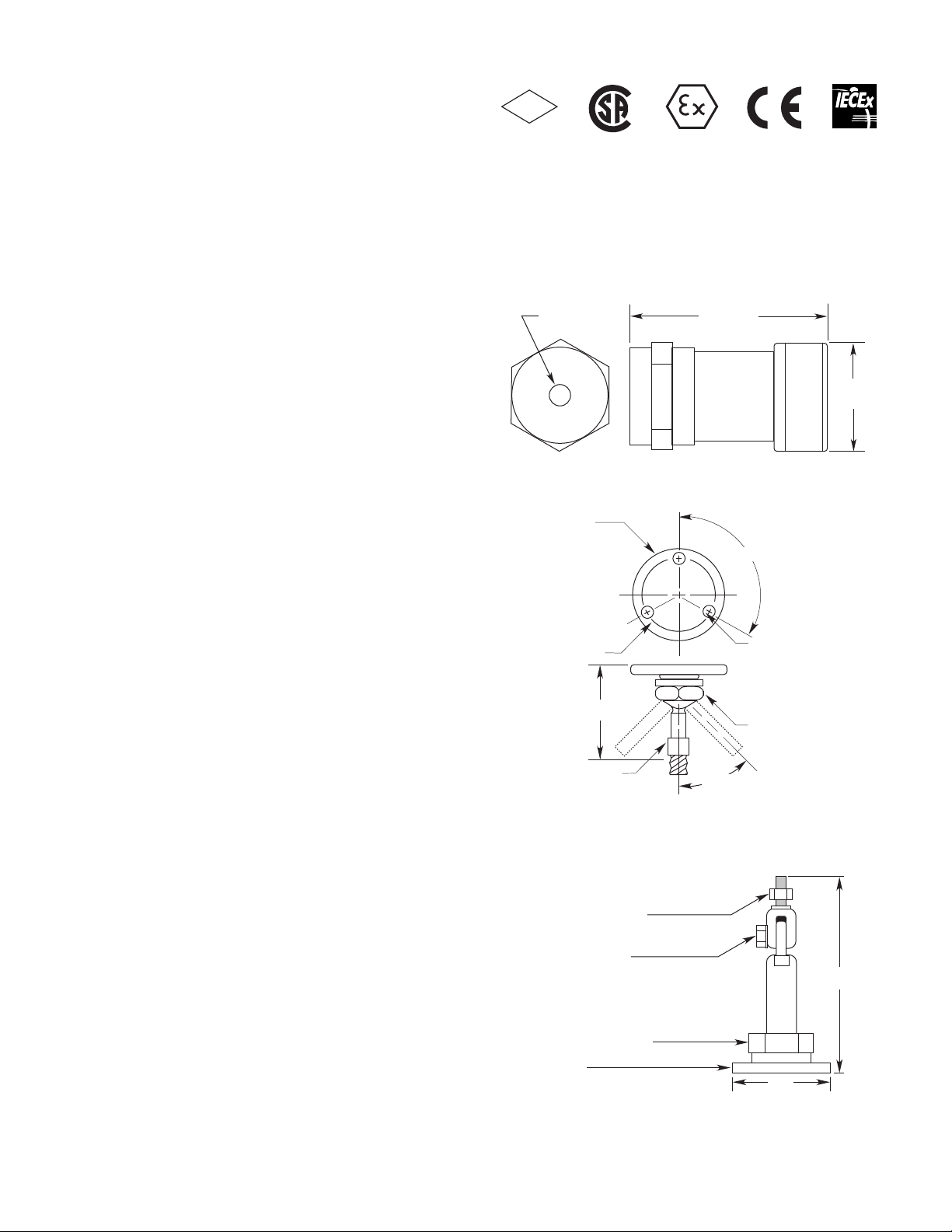

CAMERA MOUNTING

Install the swivel mounting bracket assembly on the wall.

The installation surface should be free of vibration and

suitable to receive 1/4 inch (M6) screws with a length of

at least 1 inch (25 mm), and have sufficient capacity to

hold the camera and bracket weight.

WIRE SIZE AND TYPE

General

The preferred wiring system for the xWatch Camera

Model X7050 utilizes unshielded twisted pair for the

video signal. Power wiring requires a wire gauge large

enough to ensure that 18 Vdc is available to the device

at all times.

NOTE

In applications where the wiring cable is installed

in conduit, the conduit must not be used for wiring

to other electrical equipment.

Video Cable Considerations

Proper video cable will ensure that the best quality video

is displayed on a remote monitor. Because composite

video frequencies span the range of 25 Hz to 6 MHz,

most cables will display transmission line characteristics.

Ensure that the same cable type (impedance) is used

throughout the entire length. For example, do not mix

twisted pair cable and coaxial cable without using a

balun for matching. In addition, the monitor end must

be properly terminated. Failure to properly implement

the video cabling system may result in smearing (loss

of detail) and/or loss of color and/or loss of picture sync.

The camera employs a balanced differential video

driver designed to drive twisted pair cable of 100 ohm

impedance. The best video performance in terms of

distance, video quality, and cost is attained using a 22

AWG to 16 AWG unshielded twisted pair cable of 100

ohm impedance. The wiring can be Category 2 or better,

stranded or solid.

The monitor end must terminate the video cable with 100

ohms. Most monitors have a built in termination resistor.

If the monitor uses 75 ohms instead of 100, a balun or

other matching network must be used.

There are manufacturers who support driving many

types of cable systems using active transceivers that

compensate for cable losses.

Galvanic isolation of the video may also be necessary

to avoid horizontal bars caused by line frequency

interference. This may be accomplished using isolating

active transceiving systems or passive video isolation

transformers/baluns. Specify a baseband video isolation

system with a frequency response of at least 25 Hz to 6

MHz. Small cable TV transformers will generally not work

as their frequency response is not low enough.

Power Cable Considerations

To ensure proper operation, a minimum of 18 Vdc is

required at the terminal block of the camera, considering

a worst case current draw of 0.156 Amps (2.8 Watts).