4

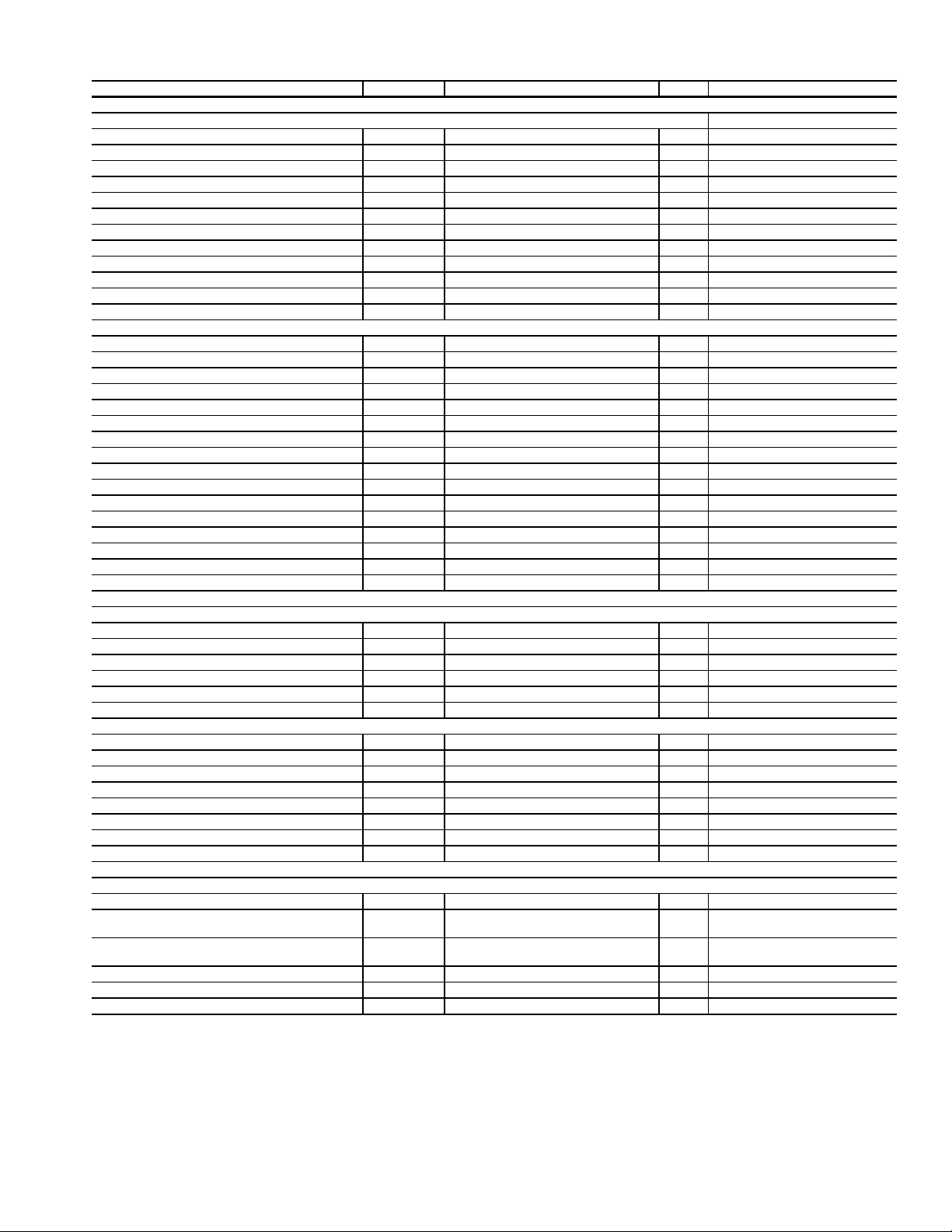

The mixed/return air sensor (MA_RA) is an air temperature

sensor located in the unit between economizer coil and

evaporator.

The entering water temperature sensor (EWT) is a probe

type sensor inserted into a copper stub at the unit water inlet

connection.

The 50XJ units can be connected to two types of building

water systems: variable and fixed or constant flow control. In

either case, the economizer water valves are opened whenever

there is a call for cooling and the inlet water temperature is cold-

er than the econimizer lockout set point.

Dependencies — Water economizer option is enabled, fan is

on, and inlet water temperature is below set point; or from “re-

mote scheduler,” or from “remote linkage.”

Economizer mode is switched to off or no start if there is no

condenser water flow, fire input is on, fan is not on, or the unit

is in unoccupied mode.

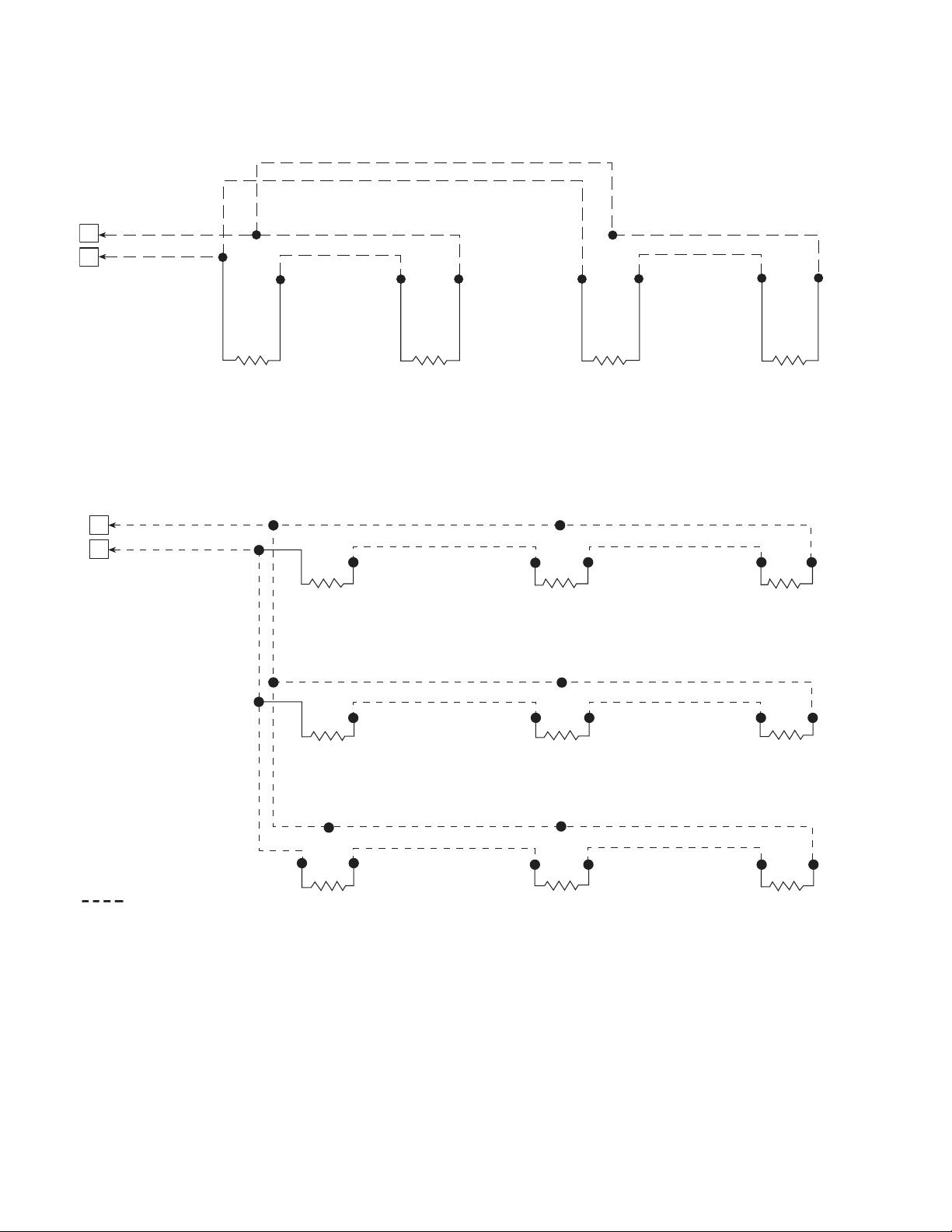

Variable Waterflow Systems — Whenever water economizer

is off, the economizer flow control valve is fully closed and the

reverse flow valve directly to the condenser is fully open. Upon

engagement of the water economizer, the economizer flow con-

trol valve should be controlled to maintain the mixed air temper-

ature as sensed by the MA-RA sensor, located between the

economizer coil and the DX (direct expansion) cooling coil at a

temperature near the supply air set point. The the reverse flow

valve will be controlled in reverse of the economizer flow con-

trol valve’s position. The following formula is an example: re-

verse/head press ctrl output = 100 – two-position/econo output.

When the unit is off, both valves are closed.

Constant Waterflow Systems — Control of the economizer

flow control valve is same as for variable waterflow systems.

Control of the reverse flow control valve position will inversely

track the economizer flow control valve, such that the total sum

of the two valves open positions always equals 100%. The only

difference between the variable waterflow system and the

constant waterflow system is that for the constant flow system

when the unit is off, the economizer valve will be closed and

the reverse flow control valve will be open.

HEATING COILS AND VALVE (PCB1) — Water or steam

heating options are factory installed. The water or steam con-

trol valve should be installed outside the unit.

HEATING - ELECTRIC HEAT (PCB1) — The controller

provides a 0 to 10 vdc signal to control remote electric heat. A

field-installed step sequencer can be used to convert this signal

in to 2, 4 or more heating stages.

A single controller output is used to drive either a hydronic

heating coil or the electric heat, so without field modifications,

these are mutually exclusive options.

HEAD PRESSURE CONTROL (PCB1) — Head pressure

control is required for unit installations that will experience en-

tering condenser water temperatures of 55 F or lower.

NOTE: Head pressure control is not needed or used in

conjunction with a water economizer. A refrigerant pressure

transducer monitors head pressure on compressor circuit 1,

allowing the unit main controller to regulate water flow rate

in main water line entering the unit (flow to all condensers).

(Water header design to the condensers will be optimized

such as to provide relative flow rates to each condenser

based on its compressor capacity, enabling successful

waterflow control at the main entering pipe.) There are two

possible water valve configurations, as outlined below.

Pressure transducer input is factory installed in the

discharge line of compressor circuit 1. It is provided 5 vdc by

the unit main controller and returns a signal 1 to 5 vdc linearly.

The sensor’s range is 0 to 550 psig.

Water Valve(s) Control

Variable Building Waterflow Systems — Variable waterflow

configurations use only one water valve in the main water

supply pipe. The factory-installed valve is a normally open

motorized variable control type. The valve is controlled by a

2 to 10 vdc signal from the main unit controller using the

reverse/head pressure control output, which modulates to

maintain the head pressure set point.

Constant Building Waterflow Systems — Constant waterflow

configurations use two (2) water valves, only one of which is in

the main water supply pipe. The second valve is located in a

bypass pipe to the main outlet water pipe branched off of the

supply pipe immediately ahead of the first valve. This valve is

same type, but normally closed and is controlled in unison with

the first valve, but opposite position, such that the total opening

of the 2 valves always equals 100%.

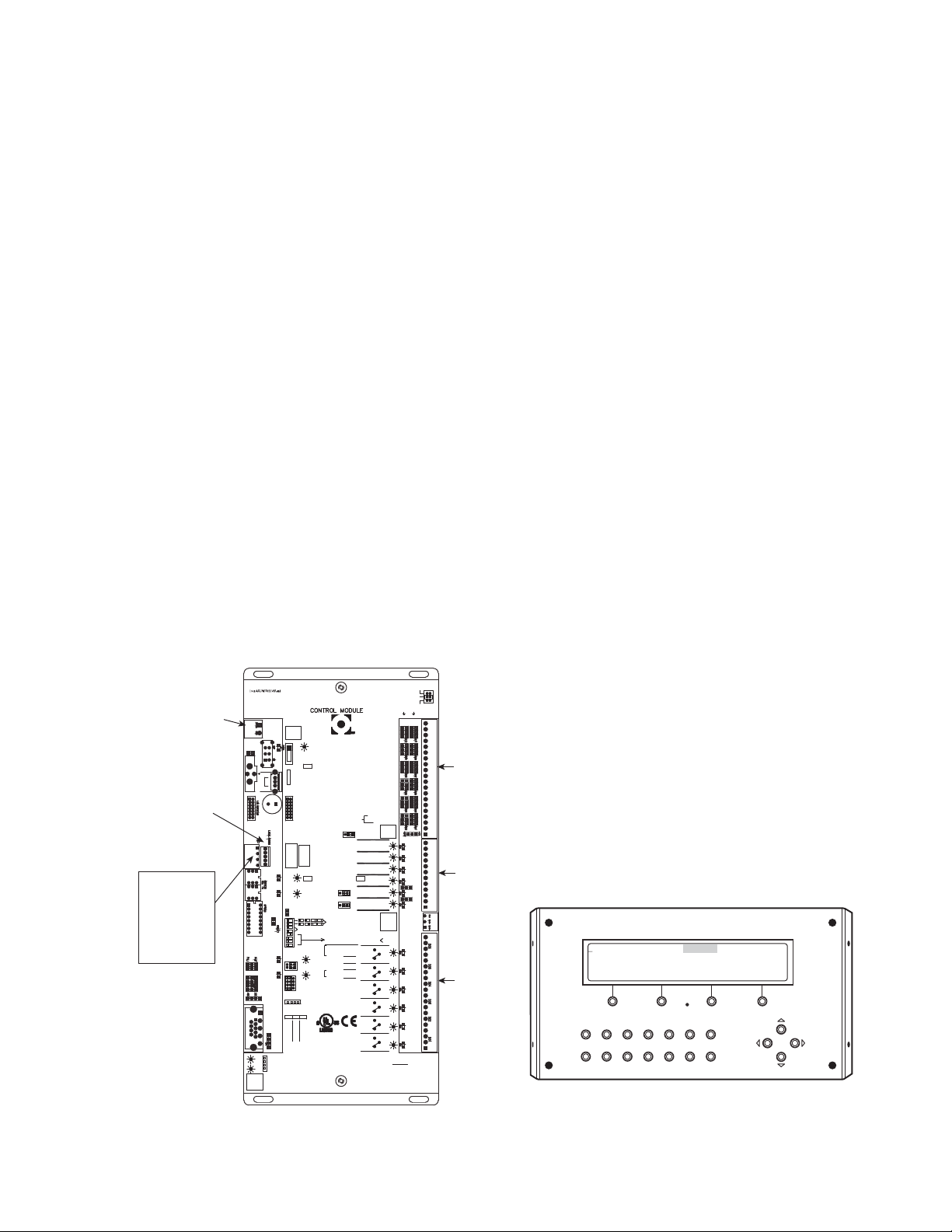

VFD BYPASS (PCB1) — The variable frequency drive

(VFD) bypass option provides backup for the VFD in VAV

units. The bypass includes a control switch to select across-the-

line operation or operation through the VFD. When the bypass

is switched to across-the-line operation, the fan will not start

until the user indicates that the VFD access doors are secure via

the BACview keypad. The controller provides an output to sig-

nal the remote VAV dampers to open fully before the fan is

started at full speed. A duct high static (DHS) switch shuts

down the fan if the duct static exceeds the switch setting.

VENTILATION OUTPUT (PCB2) — The ventilation output

is a controller output signal (available for field connection) to a

field-supplied ventilation damper(s). This signal is activated

whenever the unit is in the occupied mode.

SPACE TEMPERATURE SENSOR (PCB2) — A field-sup-

plied Carrier space temperature sensor is required to maintain

space temperature in sensor mode.

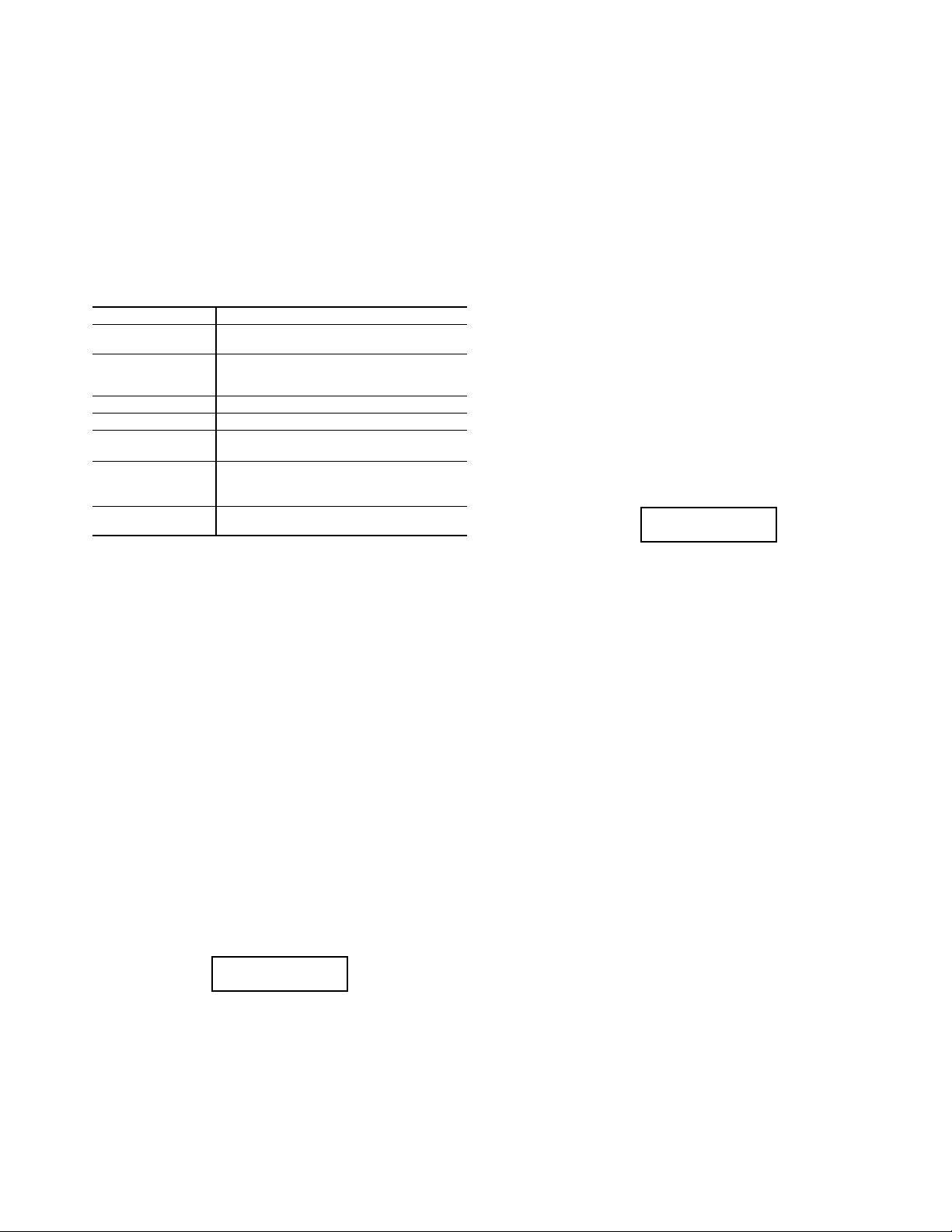

SUPPLY AIR RESET — Supply air temperature set point

may be reset using one of several sensors. In the case of multi-

ple sensors and configurations, the precedence of sensor use is

from the top of the list to the bottom:

• EWT (PCB2) — EWT sensor installed, entering water

temperature reset configuration on

• SPT (PCB1) — Space reset configuration on

• MA_RA (PCB2) — Configured for return air sensing

EXHAUST FAN CONTROL OUTPUT (PCB1) — This out-

put is activated whenever the unit is in the occupied mode. This

is a 0 to10 vdc output that controls based on the building pres-

sure input set point.

CONDENSER WATER PUMP REQUEST (PCB2) — This

relay output (provided for field connection) is used to start/stop

the remote condenser water pump. This output is engaged

when the unit is in cooling mode and the supply fan is operat-

ing. This output is also engaged if the economizer freeze pro-

tection is activated.

WATER TOWER REQUEST (PCB2) — This relay output

(provided for field connection) is used to start/stop a remote

water cooling tower. This output is engaged when the unit is in

cooling mode and the supply fan is operating.

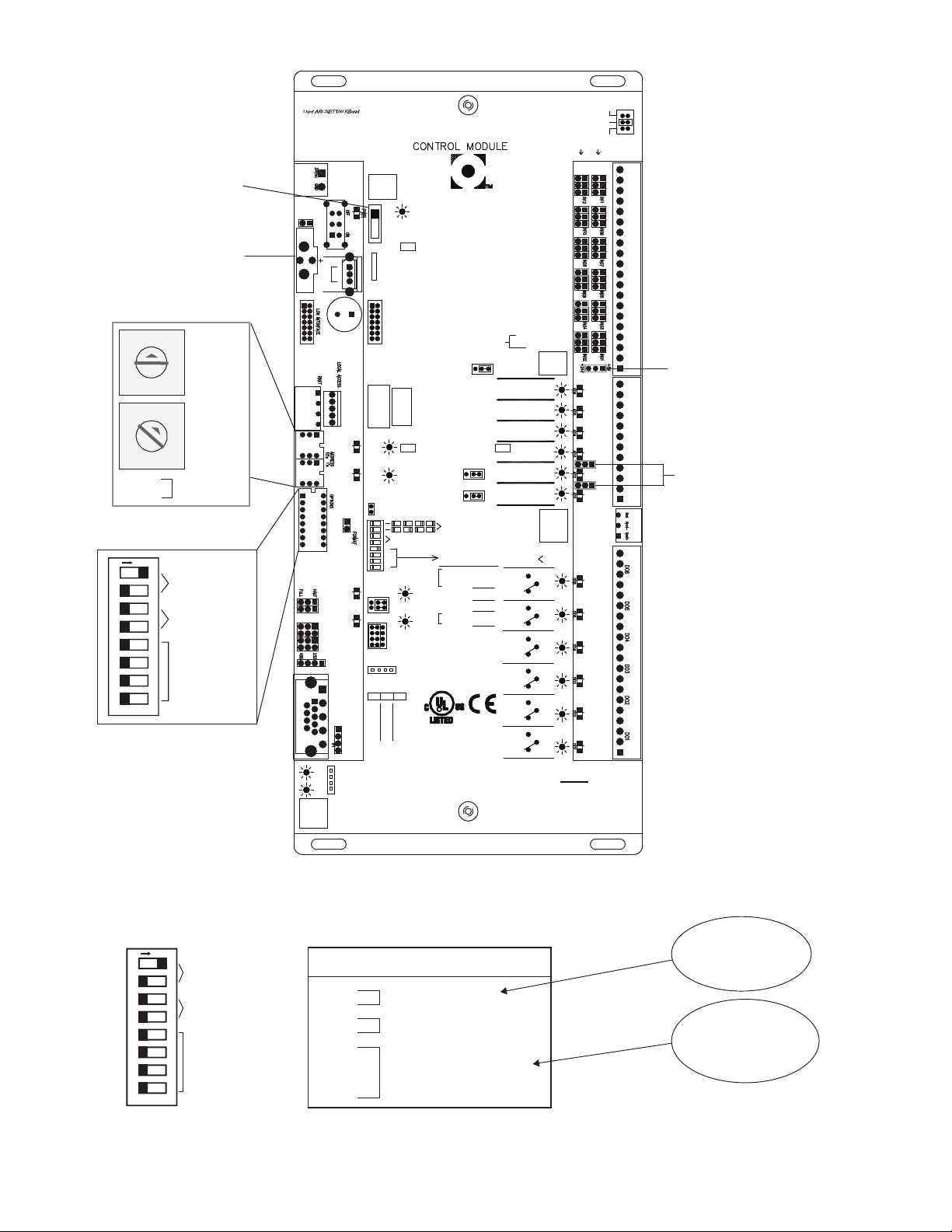

PHASE LOSS/REVERSAL PROTECTION SWITCH

(PCB2) — A phase loss/reversal switch may be installed to

detect over/under voltage conditions and phase loss or reversal.

This is a factory-installed option. This switch monitors the unit

power supply leads to detect phase loss or reversal. If the

switch detects improper phasing, an input is sent to the unit

controller, which shuts the unit down. When the switch opens,

the controller outputs are forced off, the alarm output will

close, the red alarm lamp will be lit on the BACview display,

and a system alarm will be generated. Unit reset is automatic

when the voltage and power phases have been restored.

FREEZE THERMOSTAT (FREEZ) (PCB2) — The economiz-

er freezestat, used in conjunction with an optional water