3

Contents

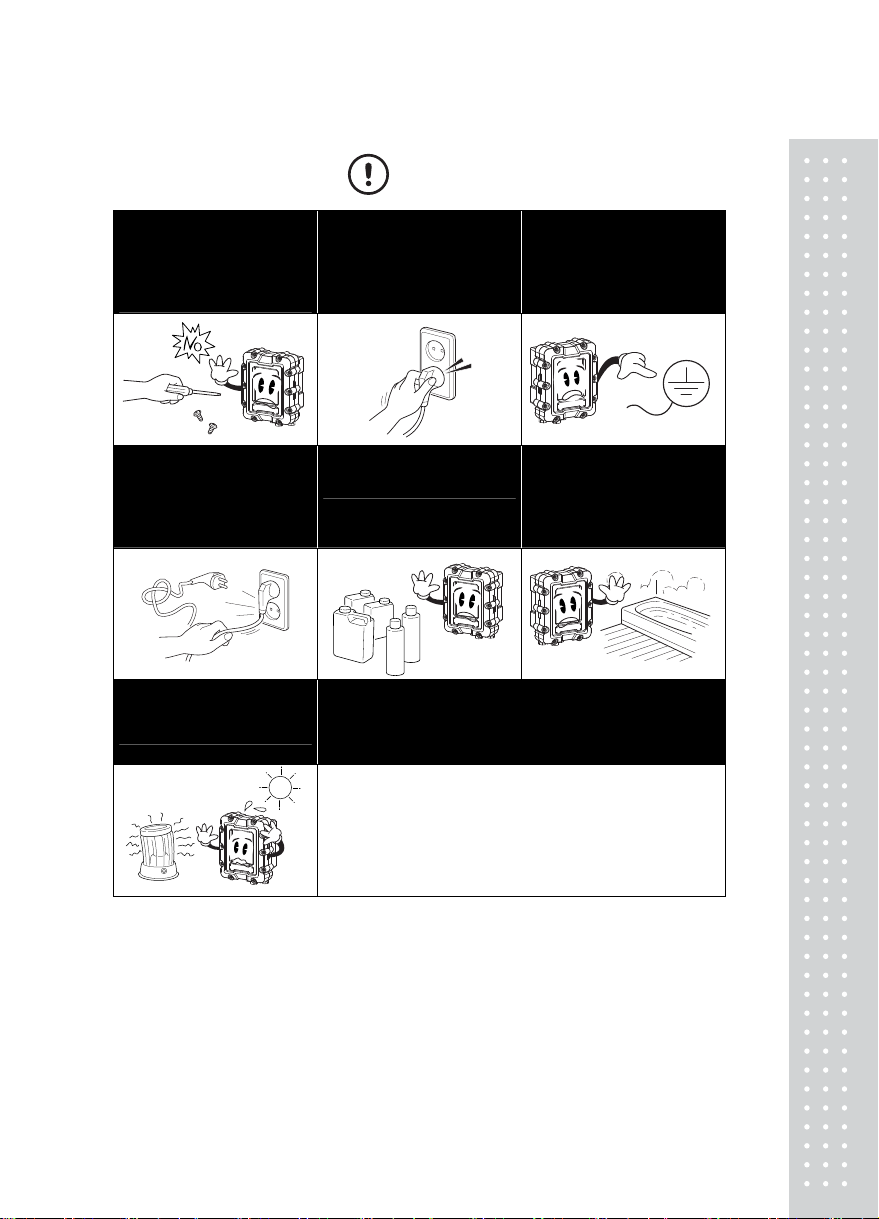

Cautions for Safety...................................................................................6

1. Normal Requirements .........................................................................9

1.1 Application Range...............................................................................................................9

1.2 Transport, assembly and installation.................................................................................9

1.3 Function, Operation and Use.......................................................................................... 13

1.4 Maintenance and Cautions ............................................................................................. 15

2. Technical Specifications...................................................................16

2.1 Product Specifications ..................................................................................................... 16

2.2 Product Labelling ............................................................................................................. 16

2.3 Product Structure and Composition ............................................................................... 17

2.4 Handling Cautions ........................................................................................................... 17

3. Features ...............................................................................................18

3.1 Features............................................................................................................................ 18

3.2 Main Functions................................................................................................................. 18

3.3 Product Specifications ................................................................................................... 19

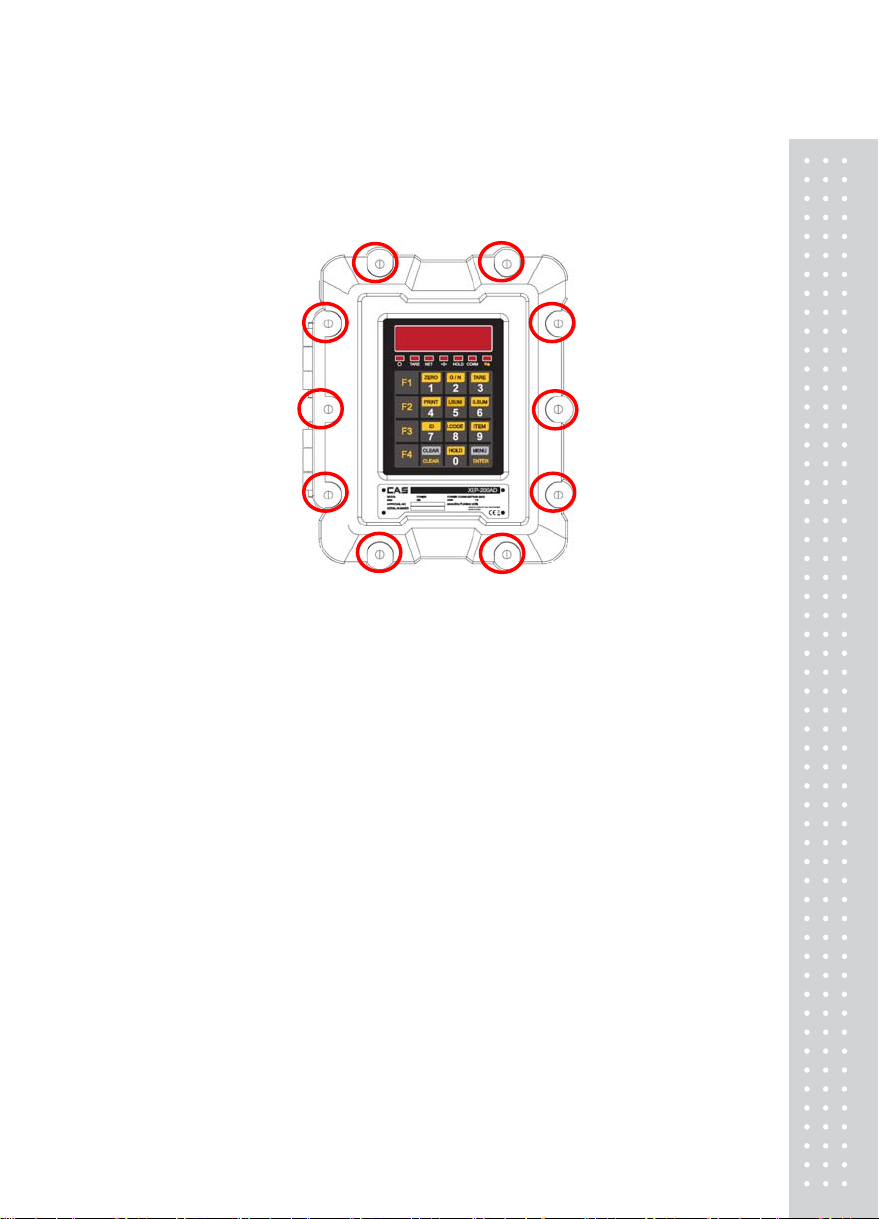

4. External Explanation..........................................................................21

4.1 External Specifications .................................................................................................... 21

4.2 Frontal Surface Explanation............................................................................................ 22

4.3 Display Explanantion ....................................................................................................... 24

4.4 Key manual ...................................................................................................................... 25

5. Internal Explanation...........................................................................27

5.1 Internal Explanation......................................................................................................... 27

5.1.1 Power Connector (AC, DC) ..................................................................................... 28

5.1.2 Load Cell Connector................................................................................................. 30

5.1.3 RS-232, RS-422/485 Connector ............................................................................. 32

5.1.4 Relay Input(Option)................................................................................................... 34