INTELLIGENT CHARGING

TS25 MKII Battery Charger Analyser Operator Manual

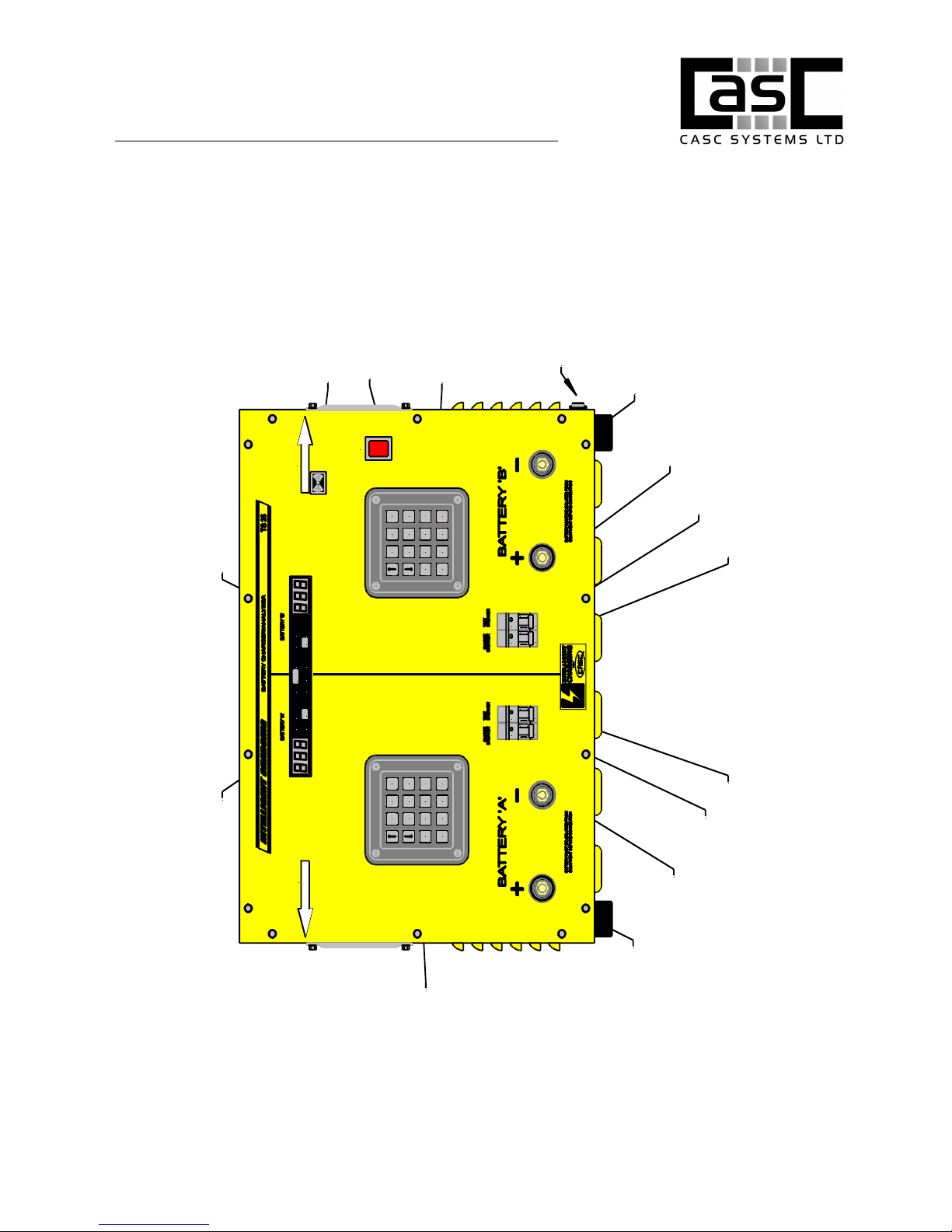

2 TS25 MKII DESCRIPTION

The TS25 MKII Dual Channel Battery Charger / Analyser is an electronically

controlled combined universal battery charging unit with built in battery analysing

capabilities It is housed in a heavy-duty metal enclosure designed to free stand on

a workbench As it is supplied it is configured for use from a standard 240V 50/60Hz

supply

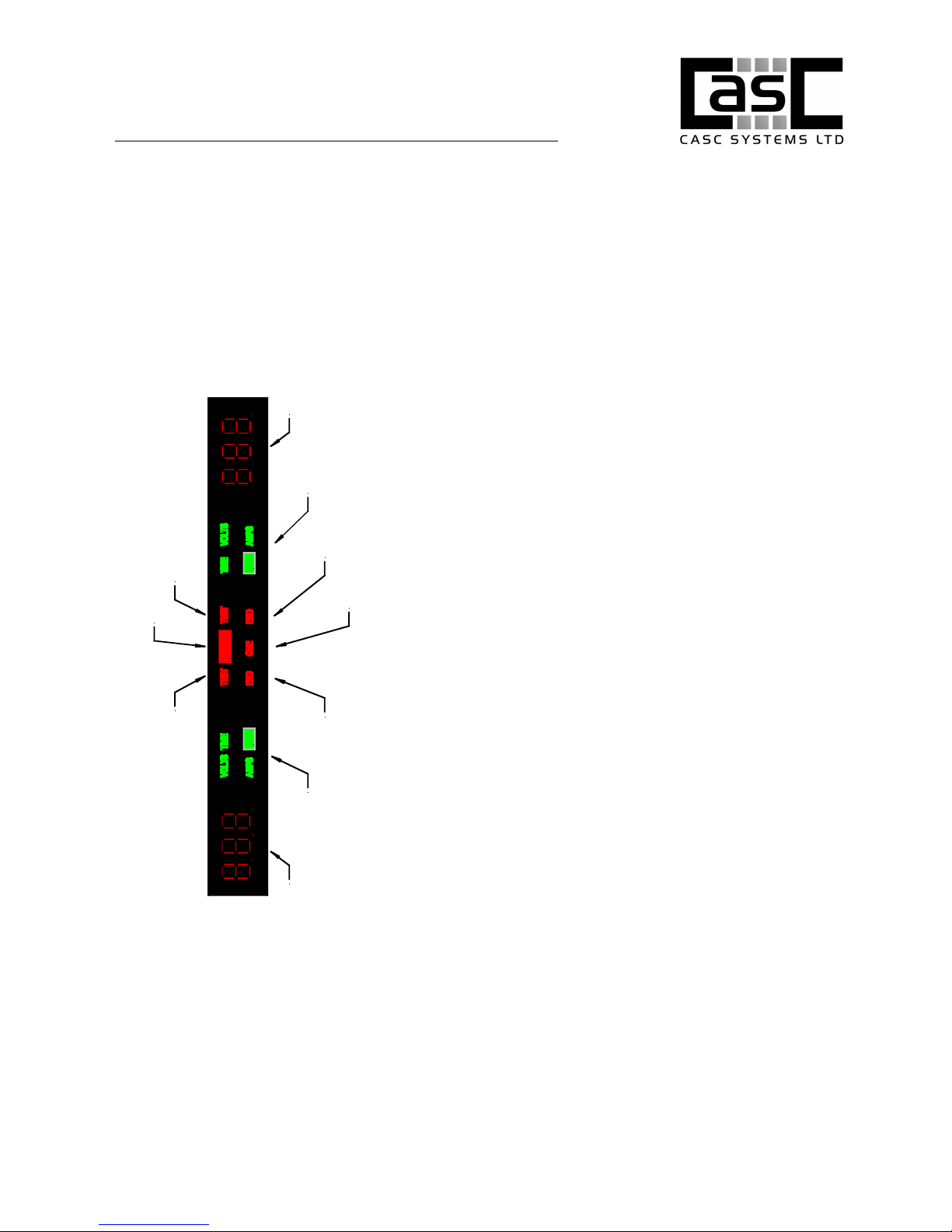

Equipment control is via an interactive numeric display and led state indicators Data

entry is via two 16-key keypads Each channel displayed data and data entry is

independent of the status of the other channel So new processes can be set up

even when the other channel is in the middle of a charge or capacity test

Battery data is stored internally in the unit in battery-backed memory A list of

commonly used batteries is included along with the accepted charging and testing

data The operator can extend or modify this list by entering the details of the

battery to be included on the display and keyboard The battery library data can be

restored to the defaults by a special key sequence permitted via the keyboard

Batteries are connected to the front of the unit by means of two individual heavy

duty connectors Connection to the battery has to be made via the appropriate

connectors for that battery Contact Intelligent-Charging for special lead sets made

to order

The TS25 MKII has extended operating capabilities compared to its predecessor the

TS25 Maximum charge current has been increased to 12A per channel, and

capacity testing still remains at 25A per channel

The TS25 MKII still has paralleling mode where using a common paired cable both

channels can be run in parallel to provide a charge capability of 24A and a capacity

test capability of 50A

There are two capacity test programs built into the unit and these can be selected

via the configuration menu and capacity testing can be performed such that it will

stop testing when a battery reached 100% or less, or alternately can carry on

capacity testing until the battery reached the set termination threshold and thus

reporting the actual battery efficiency greater than 100%

There are three charging modes built into the unit, for Lead Acid (Pb) constant

voltage charging can be performed for a fixed period of time and for Nickel Cadmium

(NiCd) constant current charging can be performed with termination on time and

over voltage parameters, and also for Nickel Cadmium batteries a new charge mode

which allows a constant current charge to be performed up until a voltage set point,

Doc: DWG1044-09-R14 TS25 MKII Operators manual.odt Page 5 of 46 Copyright Material of CasC Systems Ltd © 2015

Printed On : 02/02/15