4 | Page

TABLE OF CONTENTS

MODEL CERTIFICATIONS.........................................................................................................................................7

Safety Certifications............................................................................................................................................................... 7

INTRODUCTION ........................................................................................................................................................ 9

Read this Manual....................................................................................................................................................................9

Safety Considerations and Requirements ......................................................................................................................9

Contacting Assistance ........................................................................................................................................................ 10

Manufacturing Warranty .................................................................................................................................................... 10

Engineering Improvements................................................................................................................................................ 10

Roughing Vacuum Pump Options .................................................................................................................................... 11

Compressed Air Supply Required .................................................................................................................................... 11

Gasket Chemical Vulnerabilities...................................................................................................................................... 12

RECEIVING YOUR OVEN ........................................................................................................................................13

Inspect the Shipment........................................................................................................................................................... 13

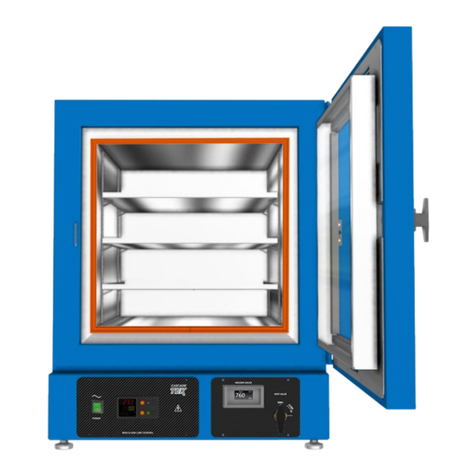

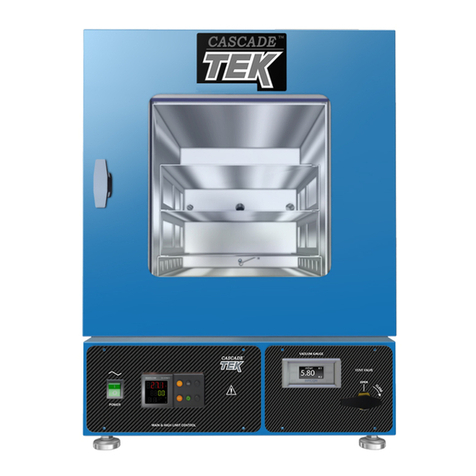

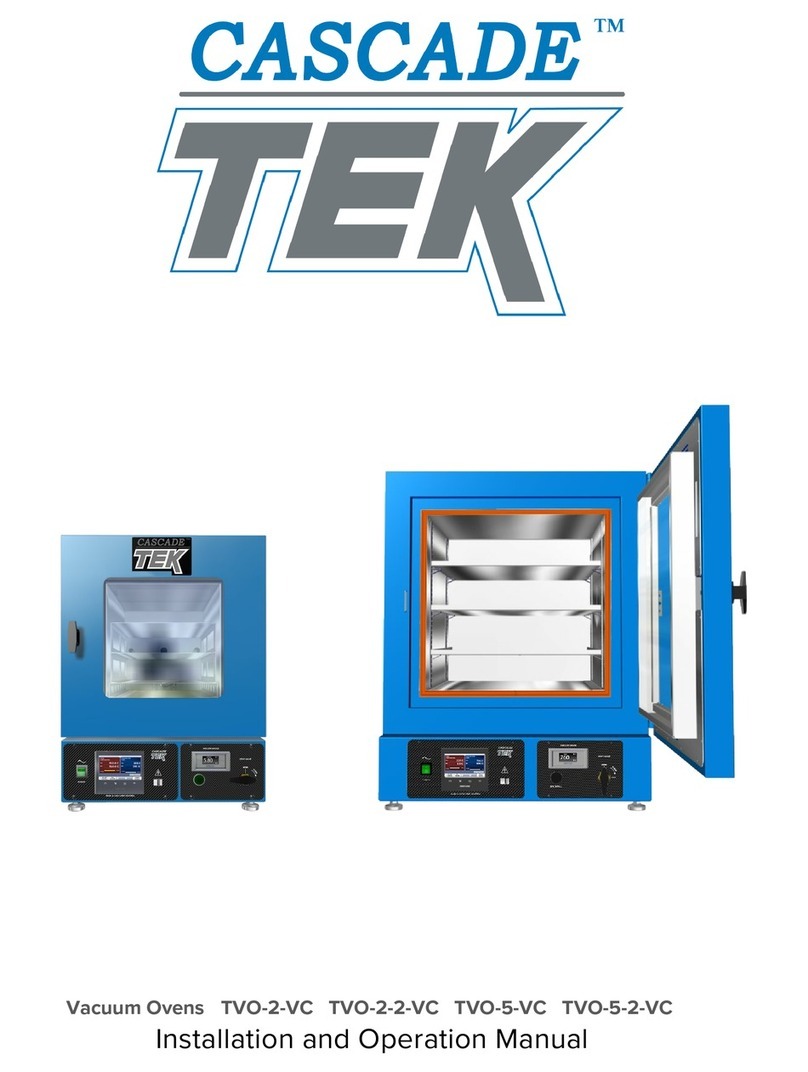

Orientation Images .............................................................................................................................................................. 14

Orientation Images .............................................................................................................................................................. 15

Dimension Visuals.................................................................................................................................................................17

Record Data Plate Information......................................................................................................................................... 19

INSTALLATION .........................................................................................................................................................21

Hardwire Requirement........................................................................................................................................................ 21

Installation Procedures Checklist .................................................................................................................................... 21

Required Ambient Conditions.......................................................................................................................................... 22

Required Clearances.......................................................................................................................................................... 22

Power Source Requirements ........................................................................................................................................... 23

Lifting and Handling ........................................................................................................................................................... 24

Leveling.................................................................................................................................................................................. 24

Install the Oven .................................................................................................................................................................... 24

Disengage the Roughing Pump Locks.......................................................................................................................... 25

Installation Cleaning........................................................................................................................................................... 26

Shelving Installation.............................................................................................................................................................27

Connect Gas Supplies........................................................................................................................................................ 28

Vent the Roughing Pump Exhaust.................................................................................................................................. 29

Verify the Oven Chamber is Empty................................................................................................................................ 30

Hardwire the Oven to Its Power Supply........................................................................................................................ 30

GRAPHIC SYMBOLS ................................................................................................................................................31

CONTROL OVERVIEW ............................................................................................................................................ 33

OPERATION.............................................................................................................................................................. 39

Operating Precautions and Hazards............................................................................................................................. 39

Theory of Operation ........................................................................................................................................................... 42

Put the Oven into Operation ............................................................................................................................................ 45

Logging In and Out ............................................................................................................................................................. 46

File Export and Import.........................................................................................................................................................47

Set the Oven Limit (OTP) Temperature......................................................................................................................... 48

Latch the Oven Chamber Door....................................................................................................................................... 49

Pump Down the Oven Chamber..................................................................................................................................... 50

End the Pump Down Process............................................................................................................................................ 51

Backfill the Chamber........................................................................................................................................................... 51

Setting a Constant Temperature Setpoint ................................................................................................................... 52

Heating Profiles ................................................................................................................................................................... 53

Oven Limit Active................................................................................................................................................................. 54

Data Ports.............................................................................................................................................................................. 56

Oven Cooldowns ................................................................................................................................................................. 56

OPERATOR MAINTENANCE.................................................................................................................................. 57

Cleaning..................................................................................................................................................................................57