IOM-123-1+6 +S DIFF 3

B. Disassembly:

1. Securely install the body (1) in a vise with the

spring chamber (2) directed upwards.

2. Remove closing cap (22).

3. Loosen sealing locknut (9) by rotating CCW.

Relax range spring (18) by turning adjusting

screw (17) CCW.

4. Draw or embed a match mark between

body (1) casting and spring chamber (2)

subassembly along flanged area.

5. Remove all body flange hardware

(7,8,30,41,42).

6. Remove spring chamber (2) and connected

parts, range spring (18) and spring button

(19).

DO NOT ATTEMPT TO REMOVE ADJUSTING SCREW

(6) FROM TOP OF SPRING CHAMBER (2). The

adjusting screw (6) is threaded up from inside the

spring chamber (2) and the CCW rotation used to

relieve range spring (14) tension will come to a stop.

At the stopping point, do not apply any torque to

adjusting screw (6) or damage may occur and render

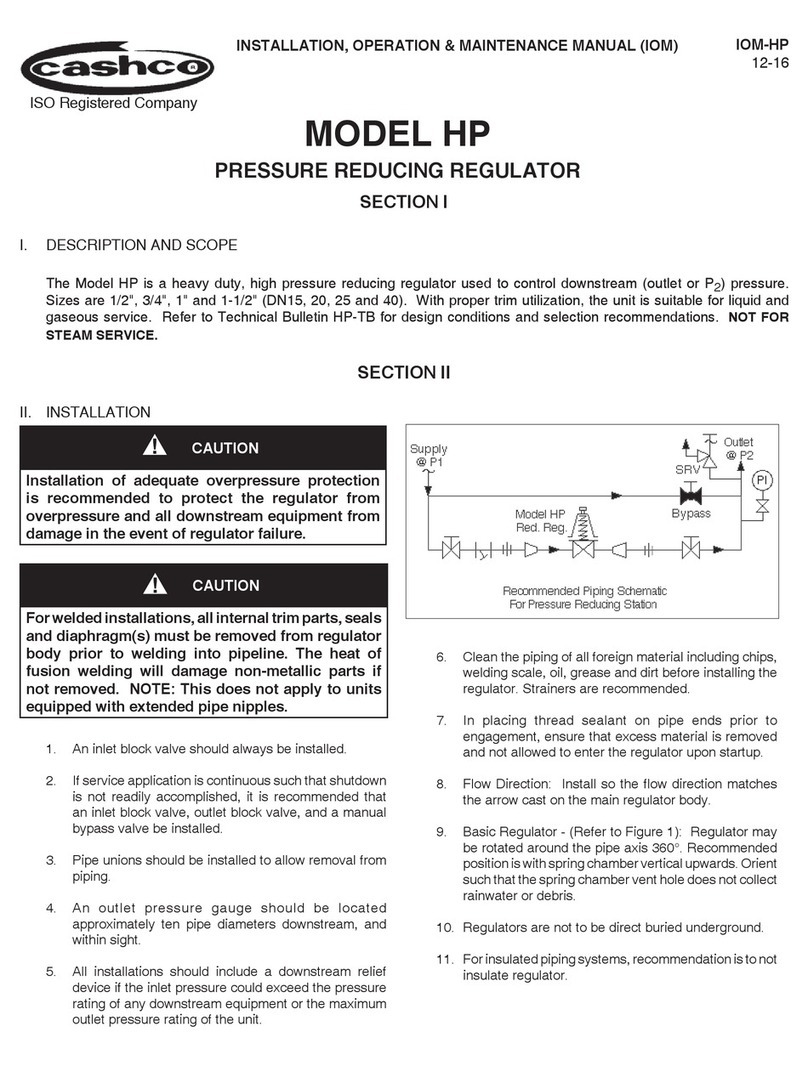

the unit inoperable. See Figure 1.

CAUTION

7. Adjusting screw (17) o-ring inspection:

a. With locknut (9) and closing cap (22)

removed, turn adjusting screw (17) CW

as far as possible by grasping the flats

on top end. Carefully reach inside spring

chamber (2) and grasp adjusting screw

(17) by hand. Remove adjusting screw

(17) by rotating CCW. See Figure 1A.

b. Inspect the backup ring (28) and quad ring

(29) for wear. If nicked or torn - replace.

NOTE: Make certain the teflon backup

ring (28) will insert into spring chamber

(2) first, before the quad ring (29). (See

Figure 7 blow-up illustration). Make sure

the quad ring (29) is on straight with

no twist. Use a good grade lightweight

grease on the ring seals (28,29).

c. Lubricate adjusting screw (17) threads.

Carefully reinstall adjusting screw (17)

up into the spring chamber (2) by rotating

adjusting screw (17) CW until top of

adjusting screw (17) protrudes from top

of spring chamber (2) (See Figure 1B.).

NOTE: Care should be taken when

holding and rotating adjusting screw (6)

so the quad ring (29) and backup ring

(28) are not inadvertently nicked or torn.

Grasp top of adjusting screw (17) and turn

CCW until rotation stops (see CAUTION

C).

d. Loosely install the lock nut (9) and closing

cap (22).

8. Liftupandremovethediaphragmsubassembly

consisting of the piston (14), piston nut (6),

diaphragm (3), diaphragm covers (24) (NACE

unit only, Cashco Dwg. 32934), pressure

plate (20), pusher plate (21), sealing washer

(27), pressure plate o-ring (31) and pusher

plate o-ring (34). Remove the flange o-ring

(32).

9. Loosen piston nut (6) and separate all parts

(3,24 (NACE units only),14,20,21,27,31,34)

of the diaphragm (3) subassembly.

Figure 1: Adjusting screw (17) o-ring inspection.

9

28

29

28

29

9

17

17

2

B. Reassembly

A. Removal

2

When body flange hardware (7,8,30,41,42) is removed

from this unit it should always be replaced with new.

The new hardware (7,8,30,41,42) must have the proper

grade specification identification markings and meet

the following standards:

1. All cap screws (7,30) and flange stud nuts (8)

must have "heavy hex heads".

2. All studs (41,42) and cap screws (7,30) must

comply with or exceed the requirements of

ASTM-A-193, Grade B7.

3. All flange stud nuts (8) must comply with

or exceed the requirements of ASTM A-194,

Grade 2H.

New body flange hardware (7,8,30,41,42) may be

purchased from Cashco, Inc. or through the OEM.

CAUTION