Xiamen Cashino Technology Co., Ltd. LP-56 Thermal Label Printer

www.csntek.com

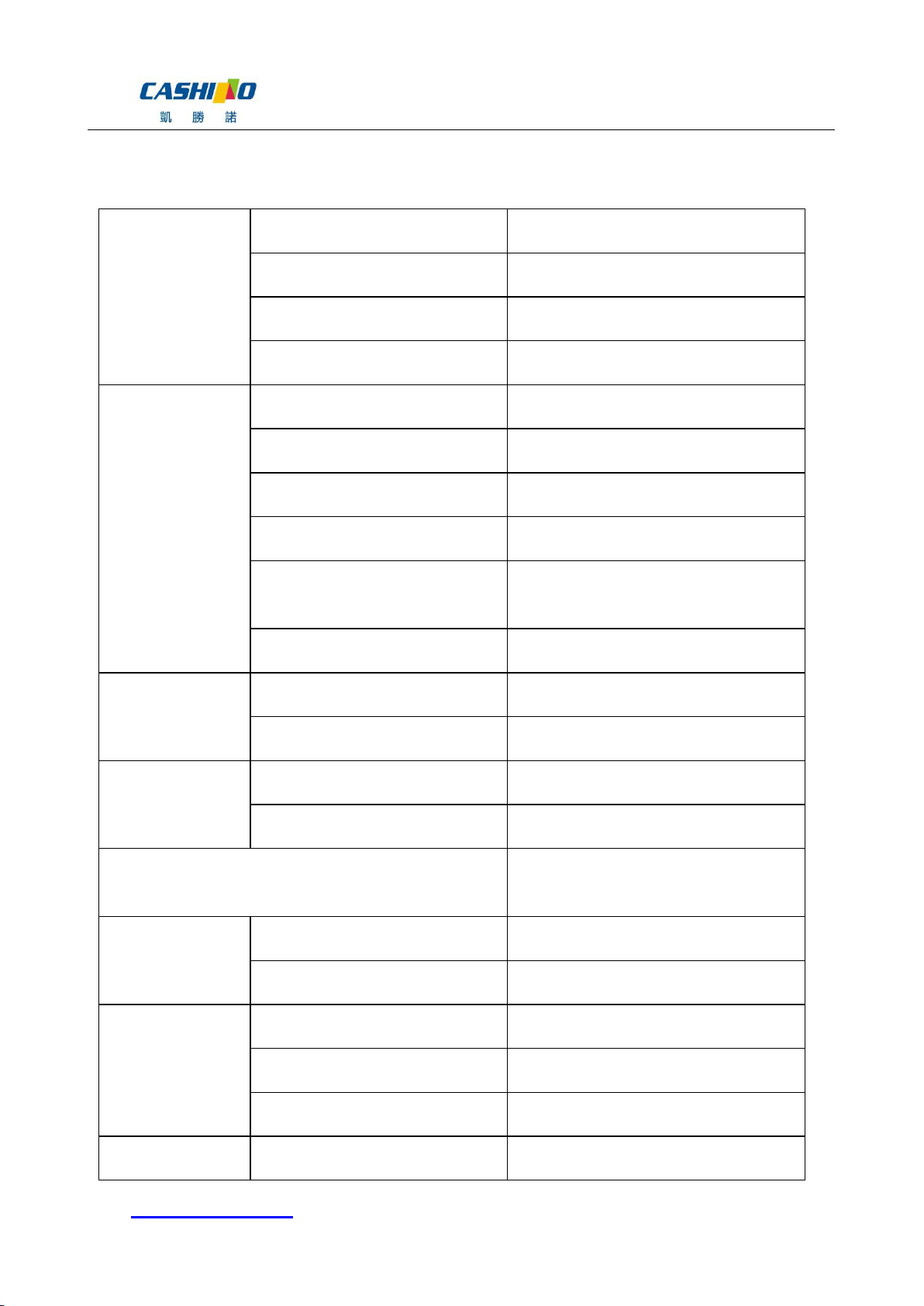

Safety instructions

Before operating the printer, please read the following precautions carefully:

1.Safety warning

(1) The print head is a heat-generating part. Do not touch the print head and surrounding parts

during and at the end of printing.

(2) Do not touch the surface of the print head and connect the connectors to avoid damage to the

print head due to static electricity.

2. Matters needing attention

(1) The printer should be placed in a flat and stable place;

(2) Leave enough space around the printer for operation and maintenance;

(3) The printer should be far away from water sources;

(4) Do not use and store the printer in places with high temperature, high humidity and serious

pollution, and avoid direct sunlight, strong light and heat sources;

(5) Avoid placing the printer in places subject to vibration and shock;

(6) Moist air is not allowed to condense on the surface of the printer. If it has already formed, do not

turn on the printer before the dew disappears;

(7) Connect the printer's power adapter to an appropriate grounded socket, avoid using the same

socket with large motors or other equipment that can cause power supply voltage fluctuations;

(8) If the printer will not be used for a long time, please disconnect the printer power adapter;

(9) Prevent water or conductive substances (such as metal) from entering the printer. Once it

happens, turn off the power immediately;

(10) The printer must not print without paper, otherwise it will seriously damage the printing rubber

roller and thermal print head;

(11) In order to ensure the printing quality and the life of the product, it is recommended to use

recommended or equivalent quality paper;

(12) When plugging or disconnecting each interface, the power must be turned off, otherwise it may

cause damage to the printer control circuit;

(13) When the printing effect meets the usage requirements, it is recommended that the user set a

low-level printing density as much as possible, so as not to affect the service life of the print head;

(14) Users are not allowed to disassemble the printer for maintenance;KP300 is 3inch kiosk thermal

printer which is consist of thermal printer head ,cutter and control board.