SATO CX Series User manual

CX200

Desktop Label Printer

®

All manuals and user guides at all-guides.com

all-guides.com

1

Rev B

SATO SERVICE MANUAL

CX Series Printers

General Information

1-1 Overview

The SATO CX Series Printers are compact desktop printers designed especially for bar

code labeling and tagging. The CX uses SATO Command Language making it simple

to integrate with any other SATO printer models. Designed for convenience the CX

has many advanced features like larger media capacity user replaceable print head

and platen and a high lift print head carriage that makes it easy to clean and load

supplies.

This manual covers in detail:

CX200DT and CX200TT

Direct Thermal and Thermal Transfer Units

Features include:

••

••

•4.1 inch Wide Print Area

••

••

•Label Width From 2 inches to 4.65 inches

••

••

•Up To 3 inches Per Second Print Speed

••

••

•203 DPI Resolution

••

••

•512K Flash and 512K RAM Memory

••

••

•2Mb or 4Mb Expanded Memory

••

••

•12 Proportional and Mono-spaced Fonts

••

••

•14 Bar Code Symbologies, Including 2D

••

••

•Parallel and Serial Interfaces

Step-by-step maintenance instructions are described in this manual. It is

recommended that you become familiar with each section before installing

and maintaining your printer.

Section

1

All manuals and user guides at all-guides.com

2

Rev B

SATOSERVICE MANUAL

CX Series Printers

1-2 Dimensions

D

H

W

CX200DT CX200TT

Weight 3.1lb./1.41 kg 3.6 lb./1.63 kg

Depth 10 in. (254 mm)

Heigth 6.6 in (168 mm)

Width 6.9 in. (175 mm)

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

3

Rev B

SATO SERVICE MANUAL

CX Series Printers

1-3 Specifications

Model CX200DT/CX200TT

Print Method Direct Thermal/Thermal Transfer

Resolution 203 dpi 8 dpmm

Max. Media Width 4.65 inches 118 mm

Min Media Width 2.0 inches 51 mm

Max. Print Width 4.1 inches 104 mm

Max. Print Length 14 inches 356 mm

Max. Print Speed 3 ips 76 mm/s

Installed RAM 512 KB, non-volatile

Installed ROM 512 KB, Flash

Communications RS232C Serial and Centronics Parallel

Max. Media Roll OD 5.0 inches 127 mm

Ribbon 460 feet (140m) Wax, Wax/Resin

418 feet (127m) Resin

0.5 inch core, Coated Side Out

Label Sensing method Eye-Mark, Gap or Notch, Fixed Position

Minimum Form Length 0.375 inches 9.5 mm

Text Fonts 12 proportional and monospaced fonts up to 12X expansion

Graphics PCX and SATO Hex/Binary

Bar Codes UPC-A/E, EAN-8/13, UCC/EAN-128, Bookland, Code 39,

I 2 of 5, Code 128, Codabar, Plessey, MSI, Code 93,

Postnet, PDF417, Maxicode

Rotation Text and bar codes can be rotated in four 90oincrements

Power 20-26 VAC 50/60 Hz or 18-26 VDC

120 VAC 50/60 Hz

230 VAC 50/60 Hz

40 W power supply provided with printer

Environmental Operating: 41o to 104oF (5oto 40oC)

Storage: - 4o to 122oF (-20oto 50oC)

RH: 25 to 85% non-condensing

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

4

Rev B

SATOSERVICE MANUAL

CX Series Printers

1-4 Attributes

READY INDICATOR

ON-LINE/OFF LINE

BUTTON

FEED BUTTON

TOP CASE

PAPER GUIDE

PLATEN ROLLER

REMOVAL ACCESS

SLOTS

WALL

MOUNTING

SLOTS

POWER INPUT POWER CABLE

ROUTING

CHANNEL

SERIAL

PORT

PARALLEL

PORT

EXTERNAL MEDIA

FEED KNOCKOUT

SECTION 1 - GENERAL INFORMATION

BOTTOM CASE

FRONT CASE

All manuals and user guides at all-guides.com

5

Rev B

SATO SERVICE MANUAL

CX Series Printers

1-4 Attributes

RELEASE LEVERS FOR

PRINT HEAD/RIBBON

MECHANISM

PAPER GUIDE (SHOWN

WITH LABELS)

PAPER GUIDE (SHOWN

WITHOUT LABELS)

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

all-guides.com

6

Rev B

SATOSERVICE MANUAL

CX Series Printers

1-5 Controls, Indicators and Connections

The following table summarizes the functions of the various printer controls

indicators and connections.

PRESS - to advance media

PRESS while pressing READY

indicator-to print test label

PRESS to pause printing during

batch mode operation

GREEN - Printer ready for data

OFF - Printer busy, or Off-Line

RED - Printer needs attention

PRESS to switch to/from Off-Line

or to reset the printer

Connect to power supply pro-

vided with printer

DB9 female connector for connec-

tion to host controller, RS232

interface

Centronics compatible connector

for connection to host controller

Push both releases toward rear of

printer to release print head

Lift to open

Push outward at hinge to remove

FEED button Advances print media

READY indicator Shows print status

ON-OFF line Places printer in On-

Line or Off-Line mode

Power input Connects to power

supply

Serial port Data input

Parallel port Data input

Print head Unlocks print head

release

Media cover Protects print media

mechanism

DEVICE NAME PRIMARY FUNCTION USE

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

7

Rev B

SATO SERVICE MANUAL

CX Series Printers

1-5 Controls, Indicators and Connections

PIN # DESCRIPTION

2 RXD (printer data input)

3 TXD (printer data output)

5 Ground

7 RTS (printer busy)

8 CTS

1,9 +5 VDC, 200 mA max

PIN # DESCRIPTION

1 Strobe

2-9 Data bits 0-7

10 Acknowledge

11 Busy

12 Out of paper

13 +5 VDC

14-15 No connection

17 Chassis ground

18 +5 VDC

31 Reset

32 Error

16,33 Signal Ground

19-30

34-36 No connection

PARALLEL INPUT

CONNECTOR

CENTRONICS 36 PIN

SERIAL INPUT

CONNECTOR DB9S

1

18

5

1

6

9

1936

BACK END OF

PRINTER

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

8

Rev B

SATOSERVICE MANUAL

CX Series Printers

POWER INPUT

READY INDICATOR

ON-LINE/OFF LINE

BUTTON

FEED BUTTON

UNDERSIDE OF PRINTER POWER

SUPPLY

AC OUTLET

1. Plug the output of the AC power supply provided with the printer

into the connector on the underside of the printer.

2. Plug the supply into an AC outlet having the correct voltage.

Important!

The required AC voltage is marked on the power supply.

Confirm that your AC voltage matches the power supply

requirements. Do not use any power supply other

then the one provided with the printer.

Note:

CX200 printers consume very little power when idle so are not equipped

with a power switch. Press the READY indicator ON-OFF (a combined

control) to reset the printer and switch from OFF-Line to On-Line mode.

SECTION 1 - GENERAL INFORMATION

1-5 Controls, Indicators and Connections

Printer Power Connection

All manuals and user guides at all-guides.com

9

Rev B

SATO SERVICE MANUAL

CX Series Printers

1-5 Controls, Indicators and Connections

Connecting the Interface Cable

AVAILABLE DB9S

SERIAL PORT PARALLEL PORT

CONNECT THIS END OF THE

CENTRONICS 36 PIN CABLE

TO THE PARALLEL PORT ON

THE PRINTER

CONNECT THIS END OF THE

PARALLEL CABLE TO THE

PORT ON THE COMPUTER

SECTION 1 - GENERAL INFORMATION

All manuals and user guides at all-guides.com

10

Rev B

SATOSERVICE MANUAL

CX Series Printers

ALSO REFER TO THE ACCOMPANYING ILLUSTRATIONS (NEXT PAGE)

1. Lift open the top case.

2. Press the two print head releases toward the rear of the printer to

unlock the print head. The print head will pop up slightly. Lift it up

until it is fully raised.

3. Remove print media (if any) or empty core from the printer.

4. Unwrap the new media and unwind a few labels from the roll. Labels

must be wound face-in for best results.

5. Slide the paper guide all the way to the right.

6. Place media roll in the tray so that the media unwinds from the

bottom of the roll toward the front of the printer. The label imaging

surface must face up as it passes under the print head.

7. Lift the print head and slip the free end of the media under the

print head.

8. Adjust the paper guide until the media is snug between the paper

guide and the left side of the paper tray.

9. Lower the print head and press it down firmly until it locks closed on

both sides.

10. Close the top case.

11. Wait until the Ready Indicator glows green then press the FEED

button to feed a label or to resume printing.

12. If the printer feeds out 7 inches of label and stops and the indicator

glows red recalibrate for the media installed. See calibration.

SECTION 1 - GENERAL INFORMATION

1-6 Printer Setup

Loading Labels or Tags

All manuals and user guides at all-guides.com

all-guides.com

11

Rev B

SATO SERVICE MANUAL

CX Series Printers

PAPER GUIDE

LIFT PRINT HEAD AND

SLIDE UNDER MEDIA

MEDIA ROLL

FEED BUTTON

READY

INDICATOR

SECTION 1 - GENERAL INFORMATION

1-6 Printer Setup

Loading Labels or Tags

PRESS BACK THE

RELEASES TO UNLOCK

All manuals and user guides at all-guides.com

12

Rev B

SATOSERVICE MANUAL

CX Series Printers

ALSO REFER TO THE ACCOMPANYING ILLUSTRATIONS

1. Lift open the top cover.

2. Press the two print head releases toward the rear of the printer to

unlock the printhead. The print head will pop up slightly. Lift it up

until it is fully raised.

3. Unwrap the new ribbon and unwind about 4" from the roll. The end

of the ribbon is attached to a take-up core.

4. Observe the notches on both ends of the supply core and the take-up

core. These notches must fit on the corresponding nibs on both the

supply and take-up spindles.

5. Roll several turns of ribbon on the take-up core winding to the under-

side as shown. The dull (coated) side of the ribbon must be on the

outside of the take-up roll.

6. Place the take-up core (ribbon unrolling from the top side) into the

left take-up spindle lining up the notches with the spindle nibs. The

take-up spindles are the take-up spindles.

7. Pull out the spring loaded knob on the right take-up spindle and place

the right end of the take-up core into the right spindle lining up the

notches with the spindle nibs.

8. Pull the ribbon down and over the print head and insert the supply

core onto the left supply spindle making sure the notches in the core

fit over the nibs.

9. Pull out the spring loaded knob on the right supply spindle and place

the right end of the supply core into the right spindle lining up the

notches with the spindle nibs.

Note:

Make sure the (coated) dull side of the ribbon is to the outside where it will be

in contact with the label media.

The CX200TT Thermal Transfer Printer transfers ink from a ribbon to the label

to produce an image.

Ribbon is N A for CX200DT

SECTION 1 - GENERAL INFORMATION

1-6 Printer Setup

Loading Ribbon

All manuals and user guides at all-guides.com

13

Rev B

SATO SERVICE MANUAL

CX Series Printers

10. Turn the take-up knob to pull the ribbon over the print head without any slack.

Check to make sure there are no ribbon wrinkles.

11. Lower the print head and press it down firmly until it locks closed on both sides.

12. Close the top case.

13. Wait until the Ready Indicator glows green and press the FEED button to feed a

label or to resume printing.

14. If the printer feeds out 7 inches of label and stops and the indicator glows red

recalibrate for the media installed. See calibration.

SECTION 1 - GENERAL INFORMATION

ROLL SEVERAL

TURNS ON THE

TAKE-UP CORE

UNWIND ABOUT 4"

SPINDLE

NOTCHES

BOTH ENDS

SPINDLE

NOTCHES

BOTH ENDS

1-6 Printer Setup

Loading Ribbon (Continued)

DIRECT THERMAL

UNIT SHOWN

(NO RIBBON)

PRESS BACK THE

RELEASES TO UNLOCK

All manuals and user guides at all-guides.com

14

Rev B

SATOSERVICE MANUAL

CX Series Printers

PLACE TAKE-UP

CORE INTO LEFT

TAKE-UP SPINDLE

SECTION 1 - GENERAL INFORMATION

SPRING LOADED

RIBBON TAKE-UP

KNOB

SUPPLY ROLL

PRINT HEAD

PULL THE RIBBON OVER

THE PRINT HEAD

1-6 Printer Setup

Loading Ribbon (Continued)

TAKE-UP

CORE

SUPPLY

KNOB

TAKE-UP KNOB

All manuals and user guides at all-guides.com

15

Rev B

SATO SERVICE MANUAL

CX Series Printers

SECTION 1 - GENERAL INFORMATION

LOWER THE PRINT HEAD

AND PRESS DOWN FIRMLY

ON BOTH HEAD LATCHES

TO LOCK THE PRINT HEAD

IN POSITION

1-6 Printer Setup

Loading Ribbon (Continued)

TURN RIBBON TAKE-UP

KNOB CLOCKWISE TO

ELIMINATE RIBBON

SLACK

Selecting the Label Sensor Type

CX200 printers support Eye-Mark gap or notch label sensing. The printer must be

set for the proper sensing method. If you are using label printing software it should

provide a means to set up these parameters. See your software documentation for

details. If you are writing your own software or controlling the printer using direct

commands you must use printer commands to set up the print mode and sensing

method. Refer to the programming manual.

All manuals and user guides at all-guides.com

all-guides.com

16

Rev B

SATOSERVICE MANUAL

CX Series Printers

1-7 Printer Test and Calibration

Preparation for Test

Cuts or gouges in the rubber drive roller

Dust buildup or other obstructions of the label sensor or sensor LED

Adhesive buildup or scratches on the print head

Adhesive buildup or other obstructions in the paper path

Any other physical damage that might affect printer alignment

These procedures run a complete set of performance tests. If the printer fails a test

troubleshoot as required then rerun all tests.

Inspect the printer for physical damage before testing or calibrating it. Inspect for:

Correct any problems found before beginning the printer calibration using the

calibration software.

NOTE:

The calibration software is DOS-based and can be run directly

from the diskette or installed on your hard drive. You must run

the software from the DOS prompt. If using Windows 95, reboot

your computer in MS-DOS mode. Do not try to run the software

in a window.

Installing the software to your hard drive:

1. At the DOS prompt insert the calibration disk in your computer's 3-1/2 disk

drive and access the drive.

2. At the prompt type dir and press the Enter key.

3. Copy the file CX200.exe to your hard drive.

4. Type CX200.exe to view the opening screen. Refer to the following pages

to continue with the program.

All manuals and user guides at all-guides.com

17

Rev B

SATO SERVICE MANUAL

CX Series Printers

1-7 Printer Test and Calibration

Preparation for Test

Running the software from your 3-1 2 drive

1. At the DOS prompt insert the calibration disk in your computer's 3-1/2 disk

drive and access the drive.

2. At the prompt type CX200.exe and press the Enter key. The opening

screen will appear.

Review the menu and make your selection. At the prompt type 1 2 3 4

or to exit the program type 0.

Description of Test Menu

1. Print Head / Status Print - Prints head pattern status. Refer to illustra-

tion on page 26

2. Change RS232 Settings - Sets the RS232 settings through the LPT1 port

3. Set Top of Form - Positions the label towards or away from the sensor.

4. Calibrate Printer - Calibrates printer to current label and/or ribbon

installed in the machine.

All manuals and user guides at all-guides.com

18

Rev B

SATOSERVICE MANUAL

CX Series Printers

1-7 Printer Test and Calibration

Print Head / Status Print

1

Access the software

1. Enter 1 at the prompt.

2. As the sequential screens appear respond to the prompts.

Refer to page 26 for an example of a test label.

All manuals and user guides at all-guides.com

19

Rev B

SATO SERVICE MANUAL

CX Series Printers

Access the software

1. Enter 2 at the prompt.

1-7 Printer Test and Calibration

Change RS232 Settings

2. As the sequential screens appear respond to the prompts.

2

All manuals and user guides at all-guides.com

Other manuals for CX Series

2

This manual suits for next models

1

Table of contents

Other SATO Label Maker manuals

SATO

SATO TG3 Series User manual

SATO

SATO SX4M User manual

SATO

SATO s84ex User manual

SATO

SATO CLLM Basic 412e User manual

SATO

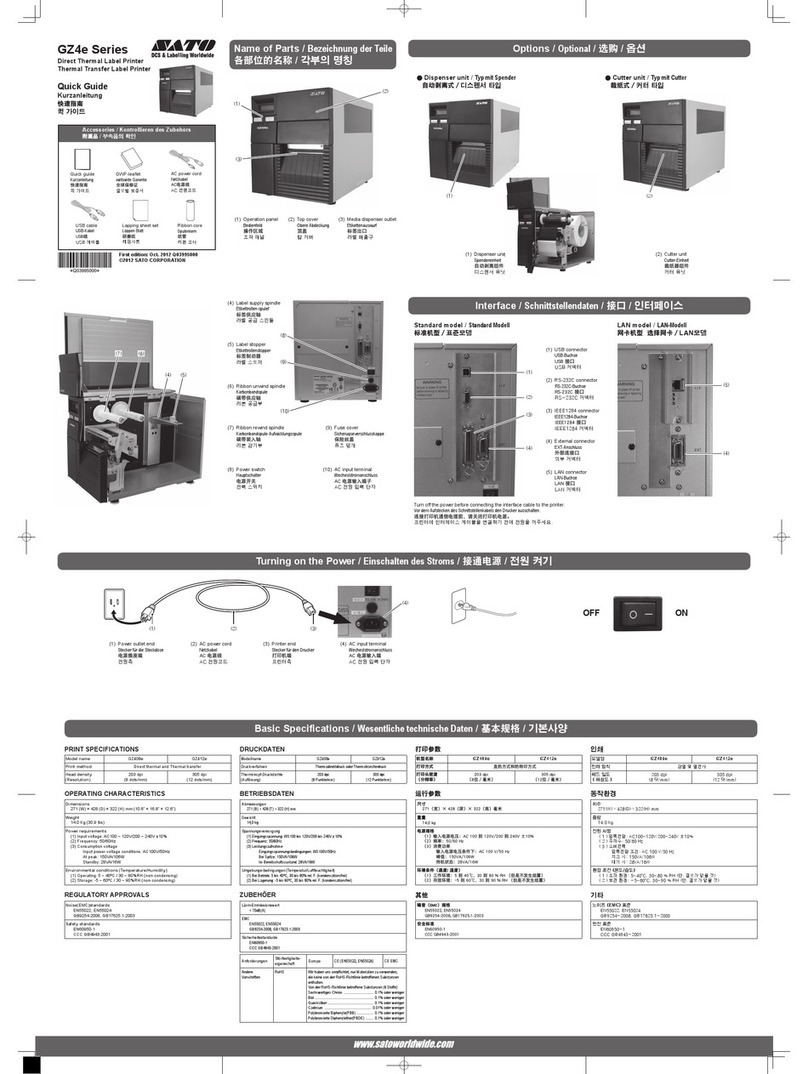

SATO GZ4e Series User manual

SATO

SATO CL4NX RIDF User manual

SATO

SATO LM400e Series User manual

SATO

SATO SG112-ex User manual

SATO

SATO CL4NX RIDF User manual

SATO

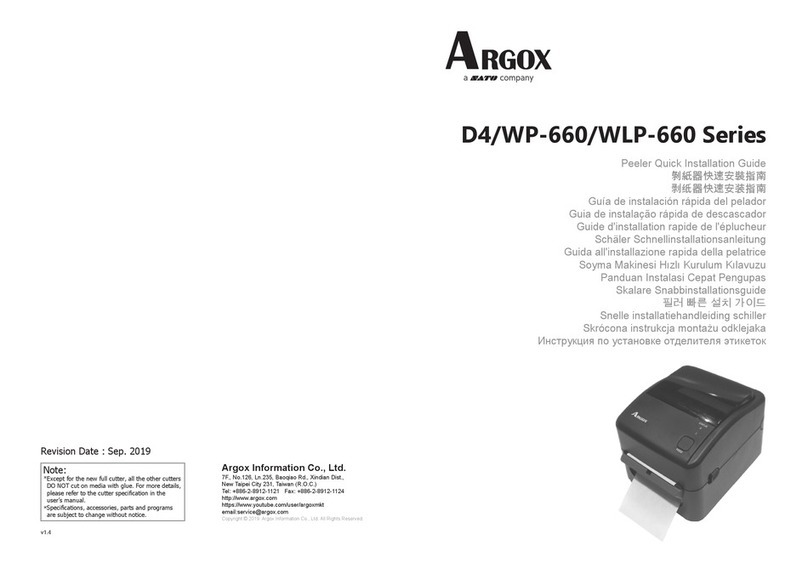

SATO Argox D4 Series User manual