Non contractual document - Cassese France®- Document non contractuel

1 - PRESENTATION

A) INTRODUCTION

Thanks for having purchased the CS20 CART underpinner and for your trust in Cassese®

and manufacturing highest quality underpinners, for which we are world-famous. The

Joining operation is carried out by using Genuine Cassese®Cartridge Wedges, specially

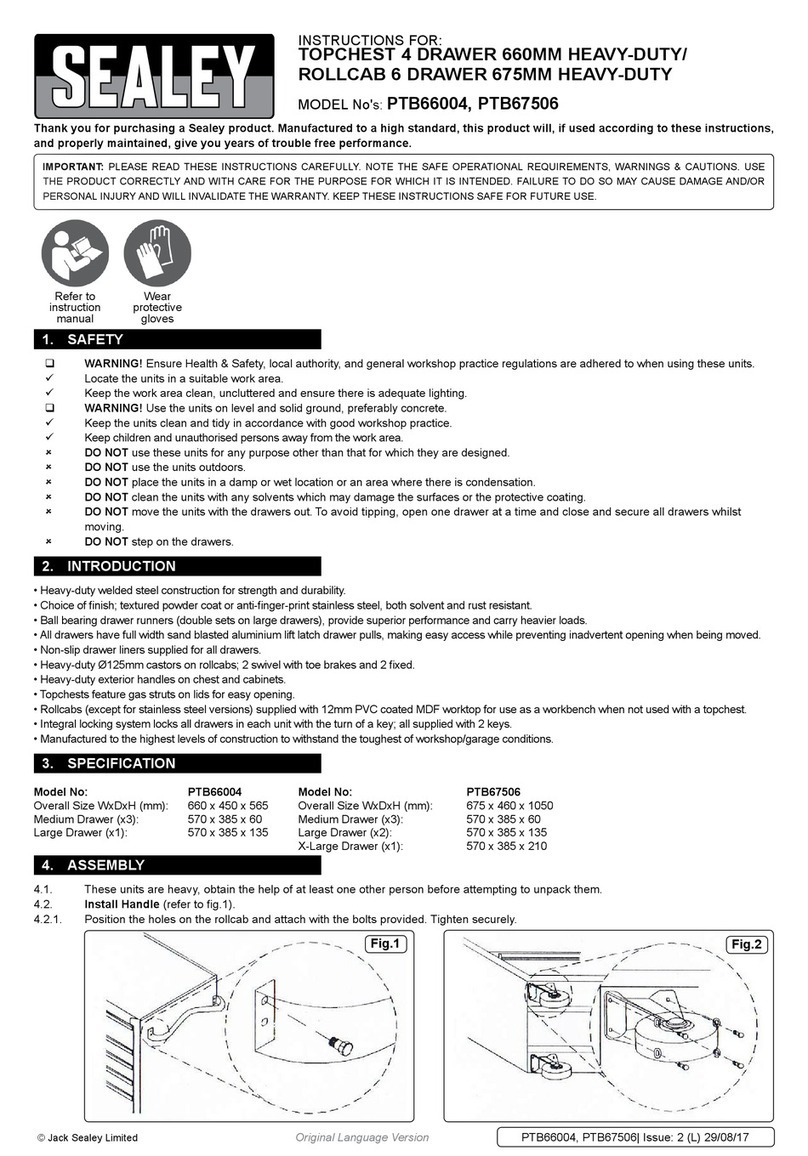

B) ACCESSORIES SUPPLIED WITH THE MACHINE

A) 1 Magnetic adjustable rod clamp + 1 Chevron holder + 1 Magnetic chevron clamp +

1 Chevron rubber.

C) 1 Wedge driver blade for using CASSESE®Genuine Cartridge Wedges.

D) 1 Allen Key 2.5 mm + 1 Allen Key 3 mm.

E) 1 Grease Tube.

C) TECHNICAL SPECIFICATIONS OF CS20 CART

1/2)

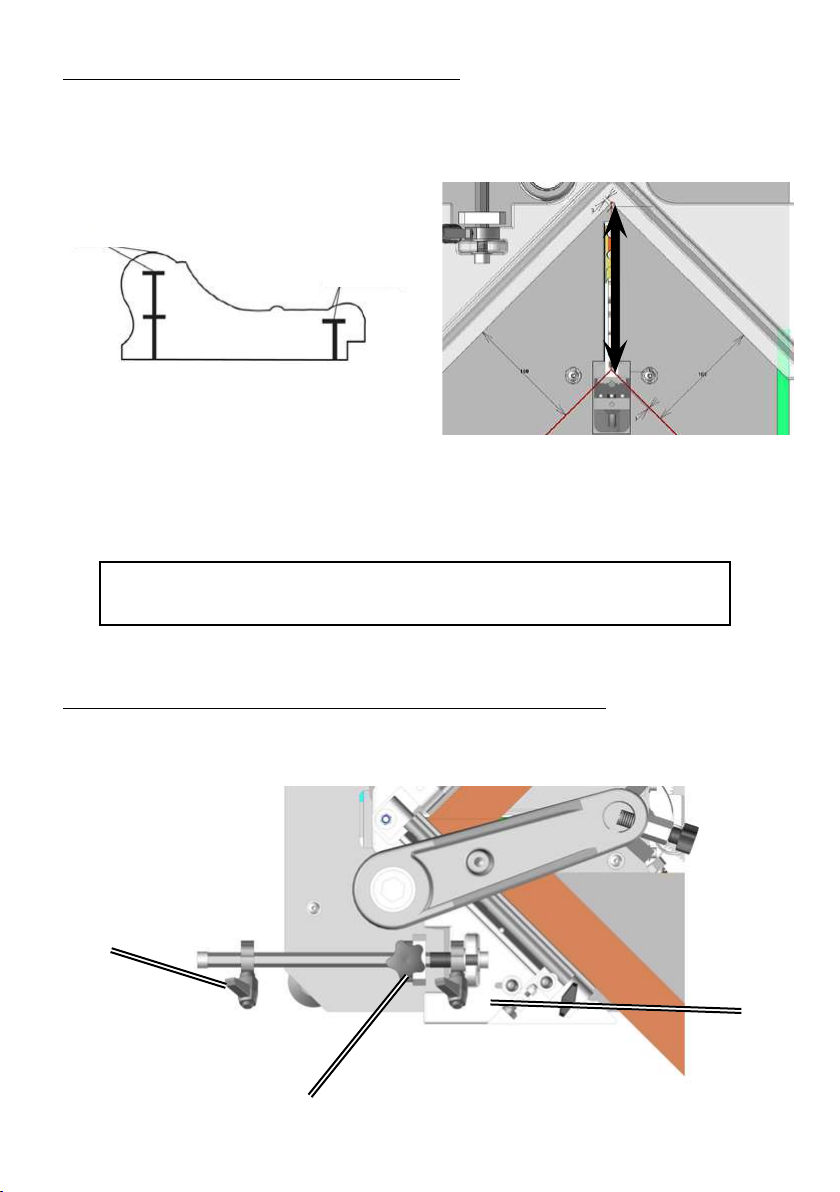

Cassese®Genuine Cartridge Wedges sizes: 5, 7, 10, 12 and 15 mm.

3 wedge types : Softwood, Hardwood & MDF. Use only Cassese®Genuine Cartridge Wedges.

3/16

1/4).

D) OPTIONS

E) GUARANTEE

One year guarantee for parts and labour against manufacturing defects. Wear parts and

those damaged as a result of non compliance with the instructions of the present manual are

parts.

2

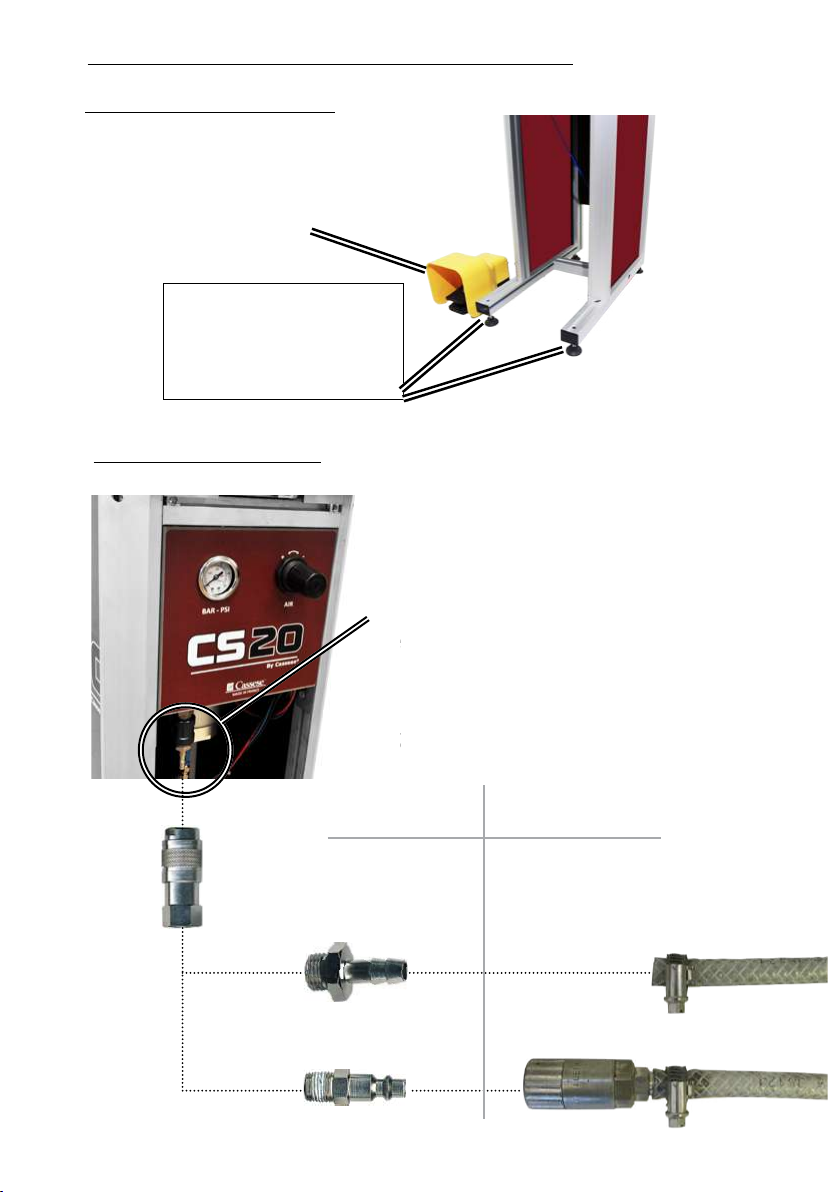

A B CDE

Z1879

Z506 Z1896Z1882

Z21525

Z21524

+

+

Z24703

Z26999