Content

1. Safety..........................................................................................................................3

1.1 Introduction....................................................................................................3

1.2 Symbols.........................................................................................................3

1.3 Intended Use.................................................................................................4

1.4 Safety Instructions for Commissioning.... .....................................................4

1.5 Safety Instructions for Operation...................................................................4

1.6 Safety Instructions for Servicing....................................................................5

2. Purpose and characteristics.......................................................................................5

3. Main technique parameters........................................................................................5

3.1 Storage................................................................................................................7

3.2 Opening the crates..............................................................................................7

3.3 Disposal of crates................................................................................................7

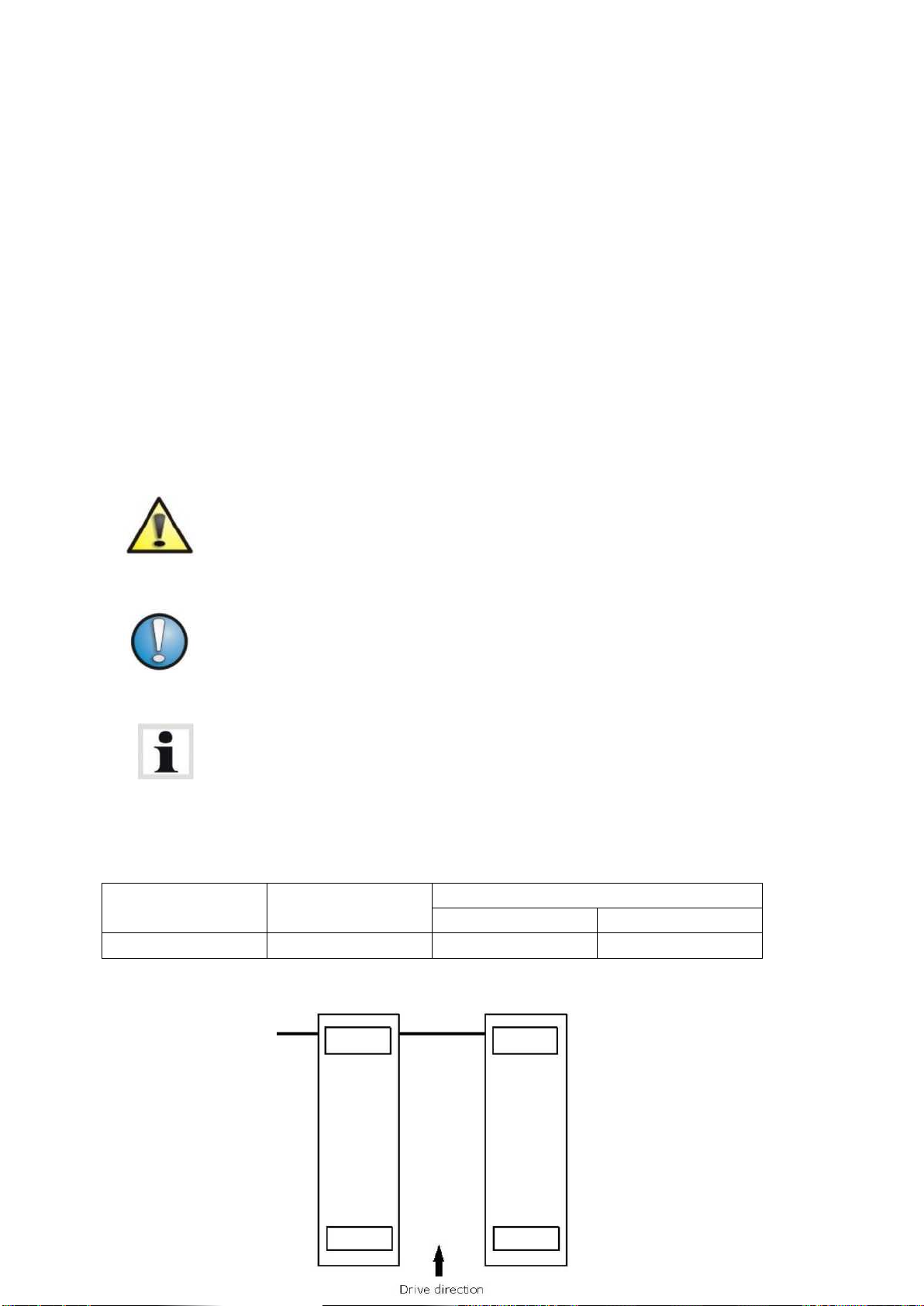

4. Transportation.............................................................................................................7

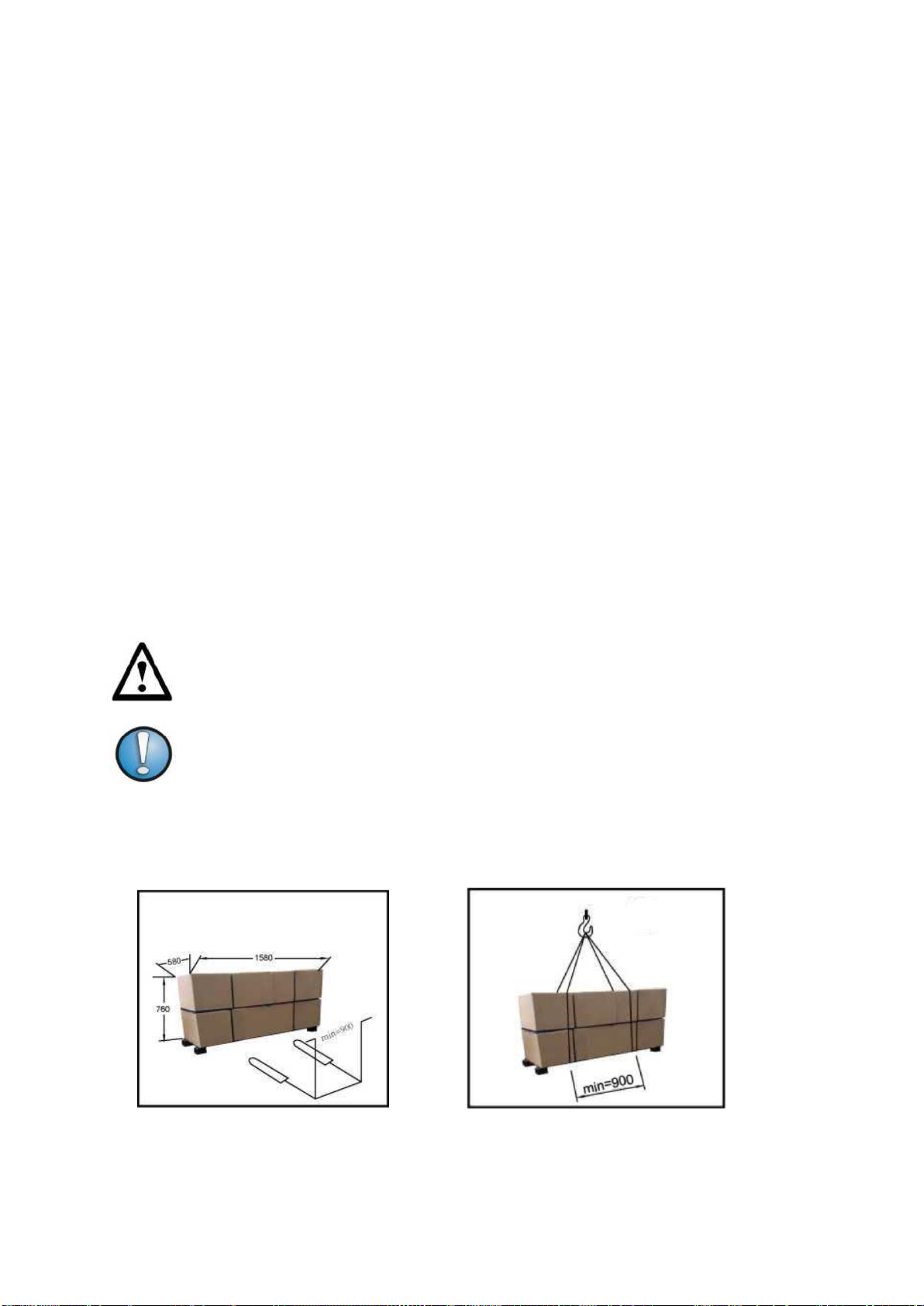

5. Unpacking....................................................................................................................8

6. Installation and testing.................................................................................................8

7. Maintenance................................................................................................................8

7.1 Maintenance Schedule.........................................................................................9

8. Operation.....................................................................................................................9

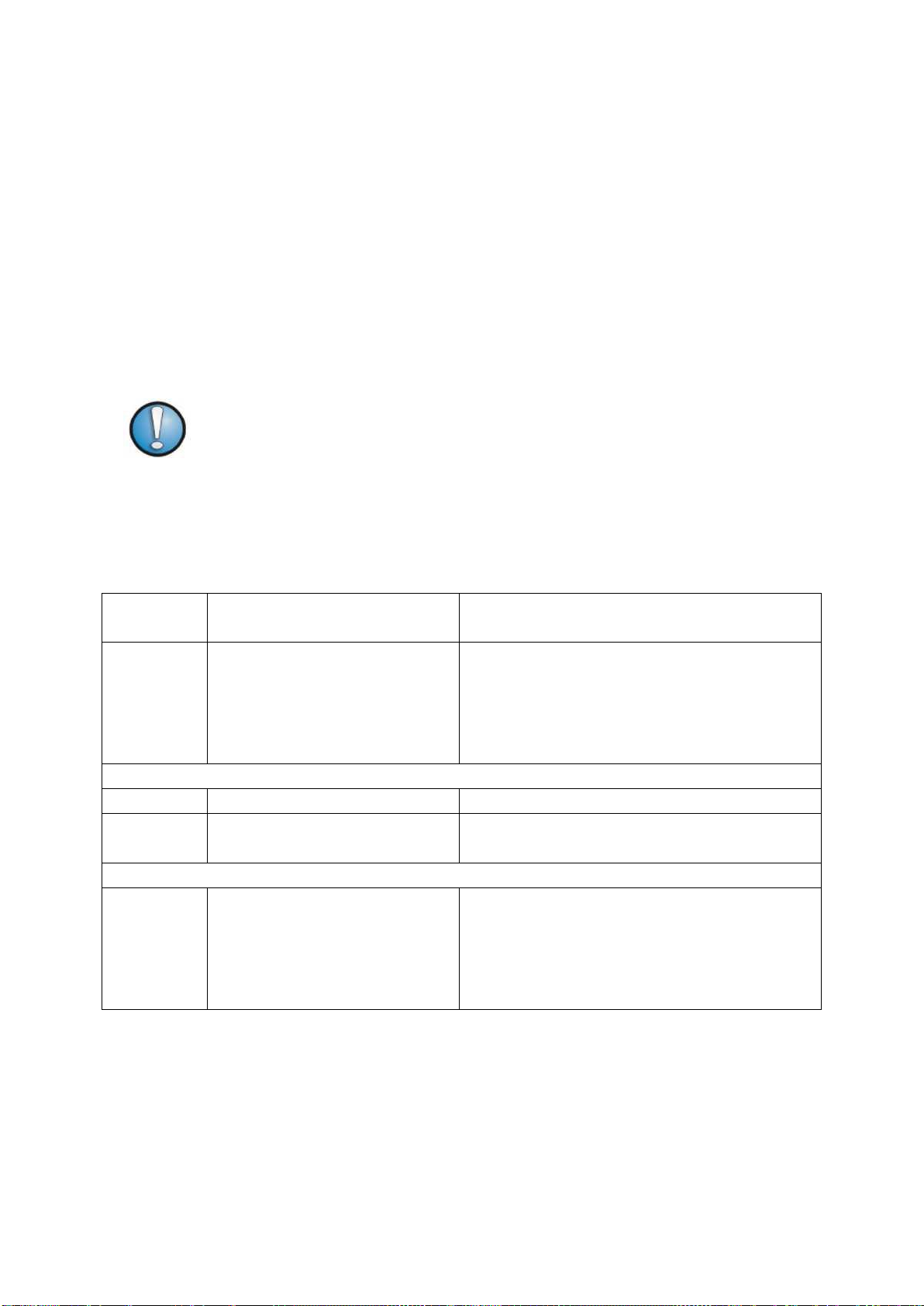

8.1 Defects / Malfunctions....................................................................................... ..10

8.2 Controls................................................................................................................10

8.2.1 Control Unit..........................................................................................10

8.3 Operation..............................................................................................................11

8.3.1 Preparations.........................................................................................11

8.3.2 Raising.................................................................................................11

8.3.3 Vehicle in Raised Position...................................................................12

8.3.4 Lowering..............................................................................................12

8.4 Protection against Unauthorized Usage...............................................................12

9. Troubleshooting...........................................................................................................13

10. Electrical Systems.......................................................................................................13

11. Hydraulic System.........................................................................................................15

12. Pneumatic System.......................................................................................................16