LAUNCH TLT830WA USER’S MANUAL

3.2 Check before Working

zCheck if the big scissor platforms can work

simultaneously and smoothly.

zCheck if the safety ratchet cover works properly

and smoothly.

zCheck if the lift will stop rise automatically when

the platforms rises to the height of 1900mm

(74.8″).

zCheck if the two small scissor tables can work

simultaneously and smoothly.

zCheck if the machine will stop rise automatically

when the small scissor tables rises to the height of

450mm (17.7″).

zCheck if there is oil leaking in the oil cylinders, oil

hoses and fittings.

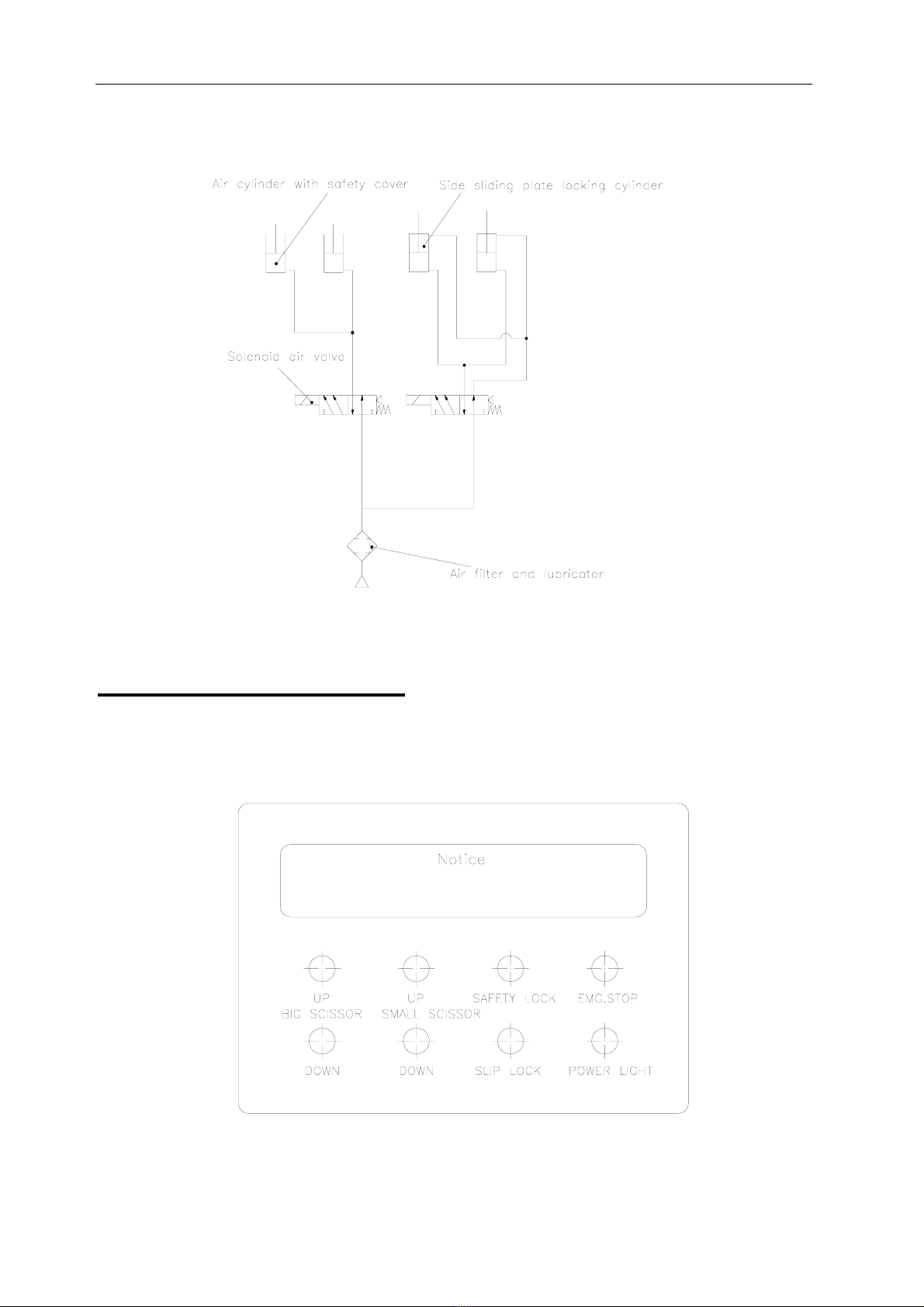

zCheck if there is air leaking in the solenoid valve,

air cylinders, pressure adjustment valves, and

fittings.

zCheck if the performance and sound of the motor

and gear pump are normal.

zCheck if the side sliding plate works normally.

zCheck if the emergency stop button works

normally.

zCheck if each part of the lift works properly.

3.3 Operating Procedure

zWhen the vehicle driving on the lift, the speed

should be under 5km/h, and make sure that the

side sliding plate of the lift is in the locking state.

zWhen the vehicle stops, the front wheels should

locate on the center of the turntable plate, and pull

the manual brake.

zPress the big scissor UP button to raise the

vehicle 20cm~30cm(7.9″~11.8″) above the

floor.

zCheck if the levelness of vehicle and lift is normal.

zKeep pressing the UP button, and raise the

vehicle to a proper height.

zPress the SAFETY LOCK button to lower the

platforms. The safety ratchets of both sides will be

engaged to ensure the safety for car servicing.

zIf tire changing or wheel alignment is need, press

small scissor UP button.

zAfter servicing the vehicle, keep the work area

clear and safe before lowering lift.

z3.4 Cautions for Operation

zThe hydraulic relief valves are well-adjusted

before leaving factory. The manufacturer will not

be responsible for any damage caused by

unauthorized adjustment.

zPeople are forbidden under the vehicle when

lifting the vehicle.

zCheck the safety lock ratchets are engaged before

servicing the vehicle.

zSelect the suitable supporting pads on the small

scissor tables. The space between the supporting

pads should be wide enough when positioning to

obtain the largest supporting area.

zWhen the hydraulic hoses are leaking because of

the damages, the leaking parts should be replaced

in time, and then add the oil to the required oil

level.

zOnce the safety ratchets are fully engaged, the

LOCK button should be released immediately. If

the Lock button is pressed for too long,too much

oil would flow back from cylinder. In this case,

the safety ratchets can not be completely released

from locked position within the set time for the

platforms to go up when the DOWN button is

pressed. This can result in no lowering action, or

lowering of only one platform, which may cause

the vehicle to fall from the lift.

8