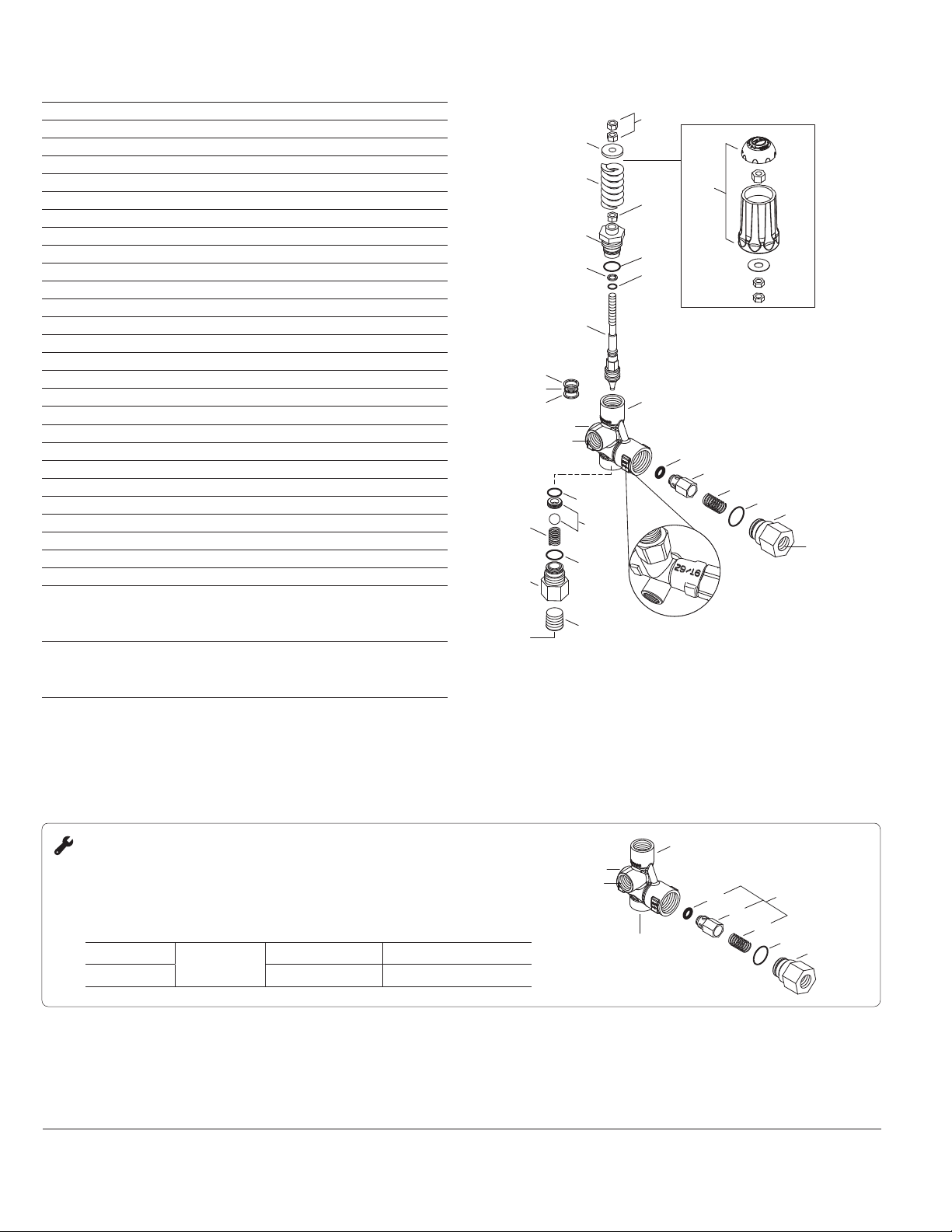

ITEM PN MATL PN MATL DESCRIPTION QTY

7537 BB 7542 BB

402 31766 NY 31766 NY Handle, Adjustment 1

403 126521 STCP R 126521 STCP R Nut, Hex Adjusting (M8) 2

408 32090 STL — — Spring Pressure (White) 7537 1

— — 32092 STL Spring Pressure (Blue) 7542 1

409 —BB —BB Nut, Hex (M8) 1

410 32115 BB 32115 BB Retainer, Spring 1

412 76170 S76170 SStem, Piston 1

414 —PTFE —PTFE Backup Ring, Piston Stem 1

415 —NBR —NBR O-Ring, Piston Stem 1

425 76727 BB 76727 BB Retainer, Piston 1

428 —NBR —NBR O-Ring, Piston Retainer 1

429 —NBR —NBR O-Ring, Piston Stem 1

430 —PTFE —PTFE Backup Ring, Piston Stem 2

434 76022 S76022 SSpring, Seat 1

435 76706 SS 76706 SS Ball and Seat Assembly (2-Piece) 1

437 —NBR —NBR O-Ring, Seat 1

439 —NBR —NBR O-Ring, Inlet Fitting 1

440 —FBB —FBB Body 1

441 —NBR —NBR O-Ring, Check Valve 1

443 76745 BB 76745 BB Valve, Check with NBR O-Ring 1

76723 BB 76723 BB Valve, Check with FPM O-Ring 1

444 76722 S76722 SSpring, Check Valve 1

446 —NBR —NBR O-Ring, Discharge Fitting 1

455 76018 BB 76018 BB Fitting, Inlet [½" NPT(F)] 1

460 76024 BB 76024 BB Fitting, Discharge [½" NPT(F)] 1

462 30533 BB 30533 BB Plug, Inlet [½" NPT(M)] 1

468 76671 NBR 76671 NBR

Kit, O-Ring (Includes: 414, 415, 428,

429, 430, 437, 439, 441, 446)

After Week #41, 2016 (7537);

Week #29, 2016 (7542)

1

—76680 FPM 76680 FPM

Kit, O-Ring (Includes: 414, 415, 428,

429, 430, 437, 439, 441, 446)

After Week #41, 2016 (7537);

Week #29, 2016 (7542)

1

*See Tech Bulletin 120 for changes prior to Week #41/2016 and Week #29/2016.

EXPLODED VIEWPARTS LIST

Bold print part numbers are unique to a particular model.

Italics are optional items.

R Components comply with RoHS Directive. MATERIAL CODES (Not Part of Part

Number): BB=Brass FBB=Forged Brass FPM=Fluorocarbon

NBR=Medium Nitrile (Buna-N) PTFE=Pure Polytetrafluoroethylene S=304SS

SS=316SS STCP=Steel/Chrome Plated STL=Steel

To convert to optional handle assembly, remove items 403 (quantity 2), 410 and 409.

Then reassemble as shown in insert.

403

410

408

415

440

409

Bypass

Discharge

441

444

414

412

430

429

430

437

439

462

Inlet

434

455

Date Stamp Location*

Read as week/year

446

460

443

Inlet

402

Optional Adjustment Handle

435

428

425

PN 993368 Rev G 20371 3/21

Inlet

440

Bypass

Discharge

441

444

446

460

443

Inlet

Remove

REGULATING UNLOADER TO RELIEF VALVE CONVERSION

The 7537 and 7542 Pressure-Sensitive Regulating Unloaders are typically used as a primary

pressure regulating device. They can be converted to a Relief Valve to be used as a secondary

pressure relief device by removing the discharge check valve O-ring, and spring.

Unloader PN Modifications Converted Relief Valve PN

7537 Remove parts

441, 443, 444

7537.100 (NBR Seals) 7537.1110 (FPM Seals)

7542 7542.100 (NBR Seals) 7537.1110 (FPM Seals)

CAT PUMPS 1681 94th Lane N.E., Minneapolis, MN 55449-4324 P: (763)780-5440 F: (763)780-2958 E: techsupport@catpumps.com www.catpumps.com

• CAUTIONS AND WARNINGS

All high-pressure systems require a primary pressure regulating device (i.e. regulator, unloader) and a secondary pressure relief device (i.e. pop-off valve, relief valve). Failure to install such

relief devices could result in personal injury or damage to pump or property. Cat Pumps does not assume any liability or responsibility for the operation of a customer’s high-pressure system.

Read all CAUTIONS and WARNINGS before commencing service or operation of any high-pressure system. The CAUTIONS and WARNINGS are included in each Service Manual and with each

Accessory Data sheet. CAUTIONS and WARNINGS can also be viewed online at www.catpumps.com/dynamic-literature/cautions-and-warnings or can be requested directly from Cat Pumps.

WARRANTY

View the Limited Warranty on-line at www.catpumps.com/literature/cat-pumps-limited-warranty

©2021 Cat Pumps Inc. All rights reserved. All data contained in this document are based on the latest product information available at the time of publication. Cat Pumps reserves the right to make changes at any time without notice.