DATA SHEET

INDUSTRIAL CLUTCHES

FEATURES

• Special e-coating offers 3 to 6 times better corrosion resistant finish.

• Special bearings with unique grease offer more

consistent viscosity at high temperatures and better water resistance for

harsh environments.

• Special projection welded coil and plate offers extra durability in heavy

vibration applications.

• Superior strength forged rotor, hub and armature offer superior flux and

maximum torque for long life.

COMMON

SPECIFICATIONS U.S. Metric

Pitch Diameter 12.4" 315 mm

Belt Type B B

Torque 100 ft./lbs. 135 Nm

Watts 50 50

Amps 4.2 4.2

Power Required 12 VDC 12 VDC

Weight (1 Pulley) 18.2 lbs. 8.25 kg

Weight (2 Pulley) 22.0 lbs. 9.97 kg

Dimensions 2.45 x 12.75" 62 x 324 mm

SPECIFICATIONS 34628 34630 34563

Pump Frame 7Frame 7Frame 15 Frame

Pulley Grooves 1 2 2

Shaft Diameter 24 mm 24 mm 30 mm

SELECTION

Select the clutch to match the pump shaft size and belt horse-

power rating.

INSTALLATION

1. Remove the four bearing cover screws on pump and discard.

2. On 7 frame plunger pumps, line up the clutch plate countersunk holes

with the bearing cover screw holes. Secure with four countersunk

head screws (M6) and lockwashers (M6) and torque per specifications.

Do not use pump bearing cover screws.

3. On 15 frame plunger pumps, using spacer as an alignment tool, slide

large diameter end of spacer first over shaft of pump. Install clutch plate

over spacer until flush against crankcase. Ensure countersunk holes of

clutch plate line up with bearing cover screw holes. Secure with four

countersunk head screws (M6) and lockwashers (M6) and torque per

specifications. Do not use pump bearing cover screws.

4. Remove spacer from crankshaft. Reverse the position of the spacer so

that small diameter end now faces the pump.

5. Mount the coil assembly onto the clutch plate and secure with three

flanged screws and torque evenly per specifications.

6. Lubricate the pump shaft with antiseize lubricant.

7. Place clutch assembly on work surface with visable bearing facing up.

8. Position pulley on clutch assembly with concave up. On dual grooves,

place second pulley with concave down.

9. Line up the six pulley holes with six clutch assembly holes. Secure with

six socket head cap screws and torque per specifications.

10. Slide the Clutch/Pulley assembly over shaft. Be certain keyway of

pump is aligned with armature keyway and insert the key into the

pump shaft. Secure with flat washer and shaft screw (M8x25) and

torque per specifications.

11. Connect the lead wire to the positive side of the electric circuit. Also

be certain there is an adequate grounded connection to the coil

assembly plate.

12. Engage and disengage the clutch to assure proper functioning. If full

load is required initially from the pump, allow clutch to engage 20-50

cycles before commencing normal operation for adequate burnishing.

NOTE: Follow standard belt mounting and center distance procedures to

determine drive pulley size, speed and horsepower per belt.

OPERATION

The clutch works with a flow switch, pressure switch or a manual on/off

switch installed in the system and connected to a 12VDC power supply.

When the trigger gun is released or the unit is manually turned off, a

signal is sent to the clutch to disengage and cease pump operation. When

operation resumes by opening the trigger gun or manually turning the

system on, the clutch will engage, starting the pump and resuming full

operation.

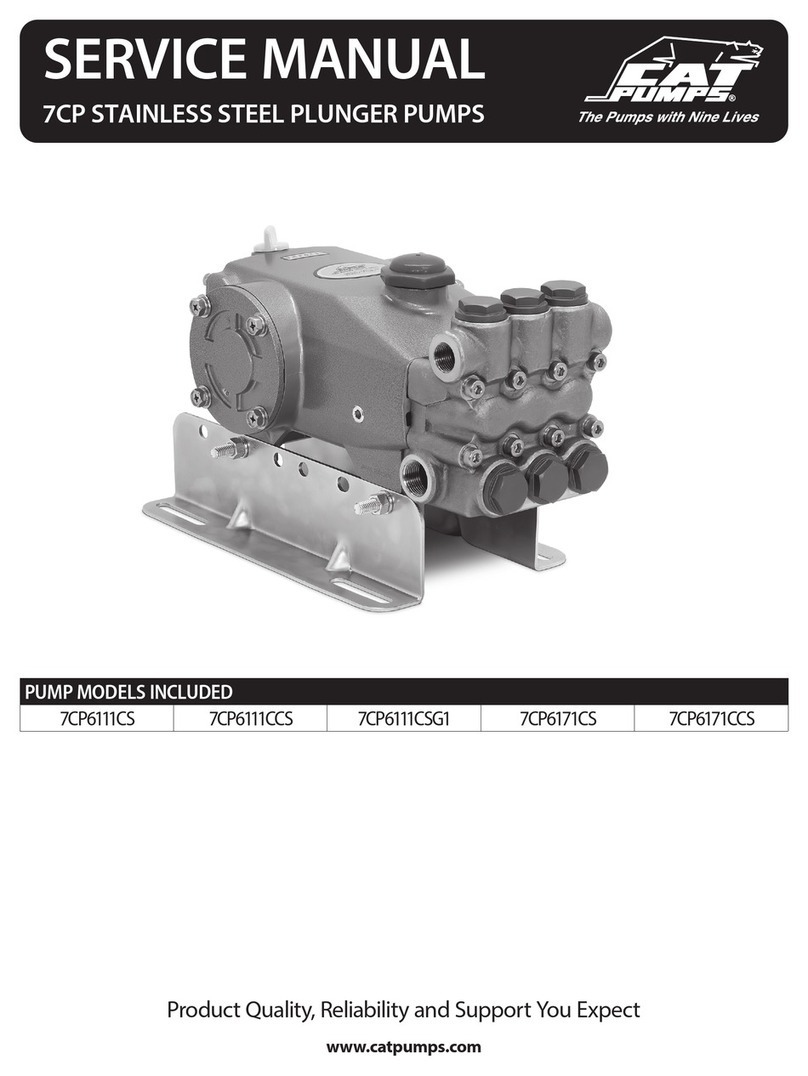

Pump Model 56 shown (pump sold separately)

7 Frame Plunger Pumps 7 Frame Plunger Pumps 15 Frame Plunger Pumps

34628 34630 34563