Published and distributed by:

CBS ArcSafe®

2616 Sirius Road

Denton, Texas 76208

A division of:

GroupCBS, Inc.®

P.O. Box 1557

Gainesville, Texas 76241

Copyright CBS ArcSafe®2019

Printed in the United States of America

Reproduction, adaptation, or translation without prior written permission is prohibited except as is allowed by law.

More Products by CBS ArcSafe®

RRS-1 –Universal Remote Racking System (Rotary)

The CBS ArcSafe® RRS-1 is a universal remote racking system capable of remotely installing and removing rotary style draw

out circuit breakers without requiring any modification to the existing switchgear. Operation of the simple to use RRS-1 is

quite intuitive and requires only minimal setup. When used properly, the RRS-1 allows technicians to remain outside of the

arc flash boundary during the potentially dangerous racking operation.

RRS-2 –Universal Remote Racking System (Non-Rotary)

The CBS ArcSafe® RRS-2 is a universal remote racking system capable of remotely installing and removing non-rotary style

draw out circuit breakers without requiring any modification to the existing switchgear. Operation of the simple to use

RRS-2 is quite intuitive and requires only minimal setup. When used properly, the RRS-2 allows technicians to remain

outside of the arc flash boundary during the potentially hazardous racking operation.

RRS-3 –Application Specific Remote Racking System (Rotary And Non-Rotary)

The CBS ArcSafe® RRS-3 product line is made up of various application specific remote breaker racking devices. Each

standalone system allows service personnel to remotely install and remove a particular type of circuit breaker safely while

stationed safely outside of the arc flash boundary during the potentially dangerous operation. The lightweight and compact

design of the RRS-3 systems makes them ideal for hard to access areas where space is at a premium.

RRS-4 –PLC Based Universal Remote Racking System (Rotary)

The CBS ArcSafe® RRS-4 universal remote racking system is an updated PLC based version of the best selling RRS-1. The

dual mode, source programmable, PLC based control system offers two different operating modes to choose from based on

user preference or the application. The RRS-4 is capable of remotely installing and removing rotary style draw out circuit

breakers without requiring any modification to the existing switchgear, allowing users to remain outside of the arc flash

boundary during the potentially hazardous racking operation.

RSA –Remote Switch Actuator

The CBS ArcSafe® Remote Switch Actuator (RSA) product line is made up of various application specific remote operating

devices. These products allow service personnel to remotely perform all aspects of an operation for a particular type of

electrical equipment from outside the arc flash boundary – reducing or eliminating the possibility of serious injury or death

resulting from an arc flash.

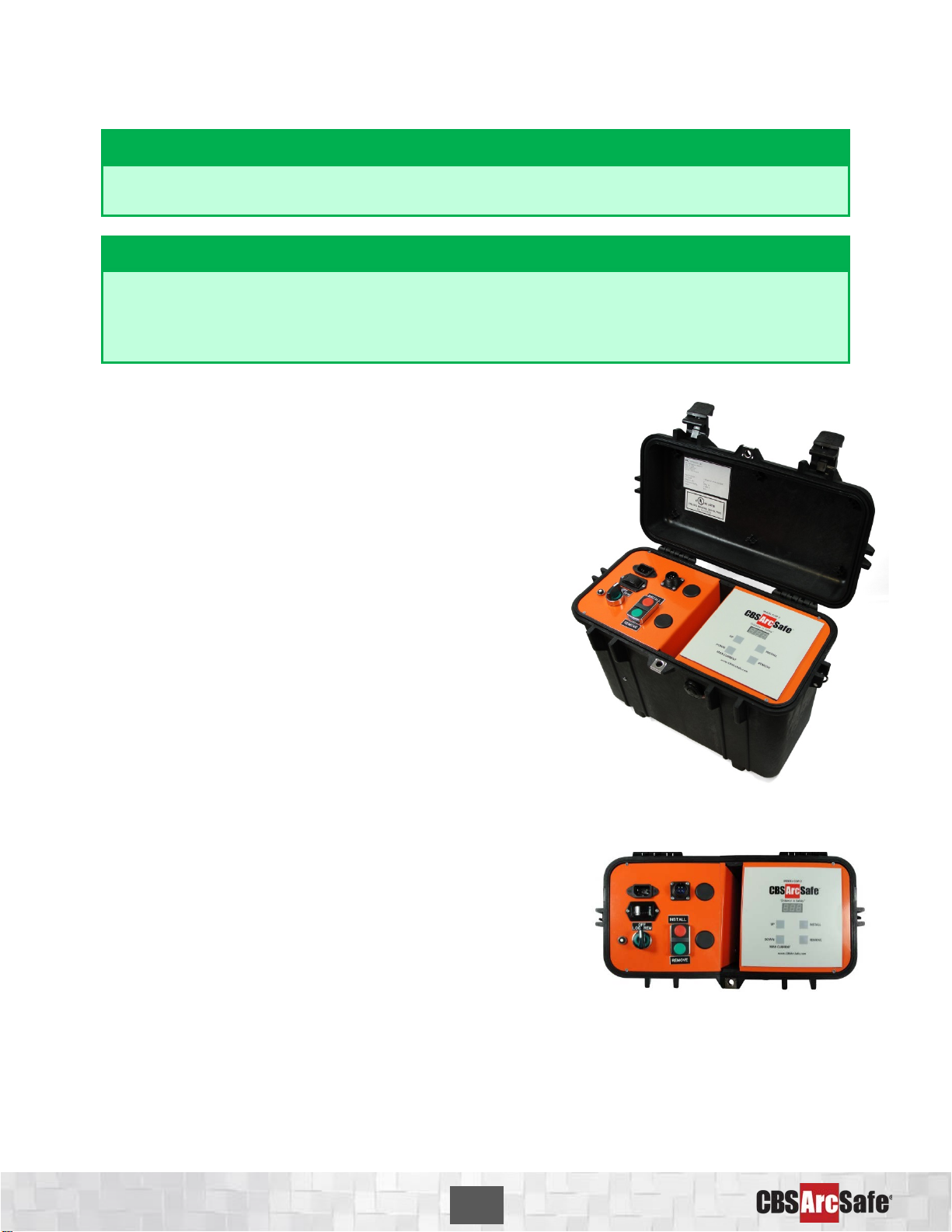

RSO –Remote Switch Operator

During a remote operation, the CBS ArcSafe® RSO functions as both the power supply and user interface for the device

being remotely operated by the user. When paired with an applicable CBS ArcSafe® device, this portable standalone

system allows service personnel to remotely perform a racking or switching procedure from outside the arc flash boundary

– reducing or eliminating the possibility of injury or death resulting from an arc flash