CDA HG6151 Quick start guide

Other CDA Hob manuals

CDA

CDA HCG 931 for Reference manual

CDA

CDA HG3601FR Reference manual

CDA

CDA HN3615FR Quick start guide

CDA

CDA HNG7410FR Quick start guide

CDA

CDA HC7621FR Quick start guide

CDA

CDA HG9321SS Quick start guide

CDA

CDA HN3621FR Quick start guide

CDA

CDA HE6051FR Quick start guide

CDA

CDA HVN 32 Series Instructions for use

CDA

CDA HN6841FR Quick start guide

CDA

CDA HC9606FR Specification sheet

CDA

CDA INDUCTION HOB HVN61/81 Instructions for use

CDA

CDA HCC663 Reference manual

CDA

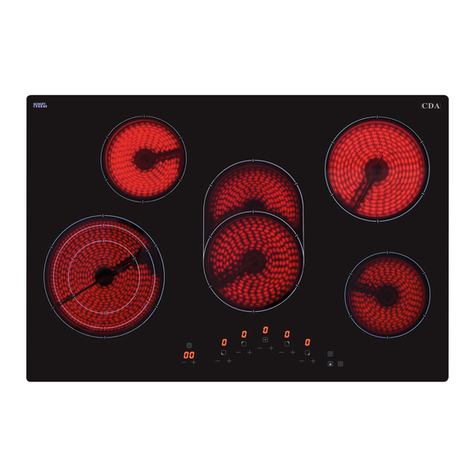

CDA hc6620 Reference manual

CDA

CDA HG7251 User manual

CDA

CDA HCG 731 Series Instructions for use

CDA

CDA hn9840 Reference manual

CDA

CDA HN9611FR Quick start guide

CDA

CDA hc3615 Quick start guide

CDA

CDA HCG 730 Users operating instructions Product guide