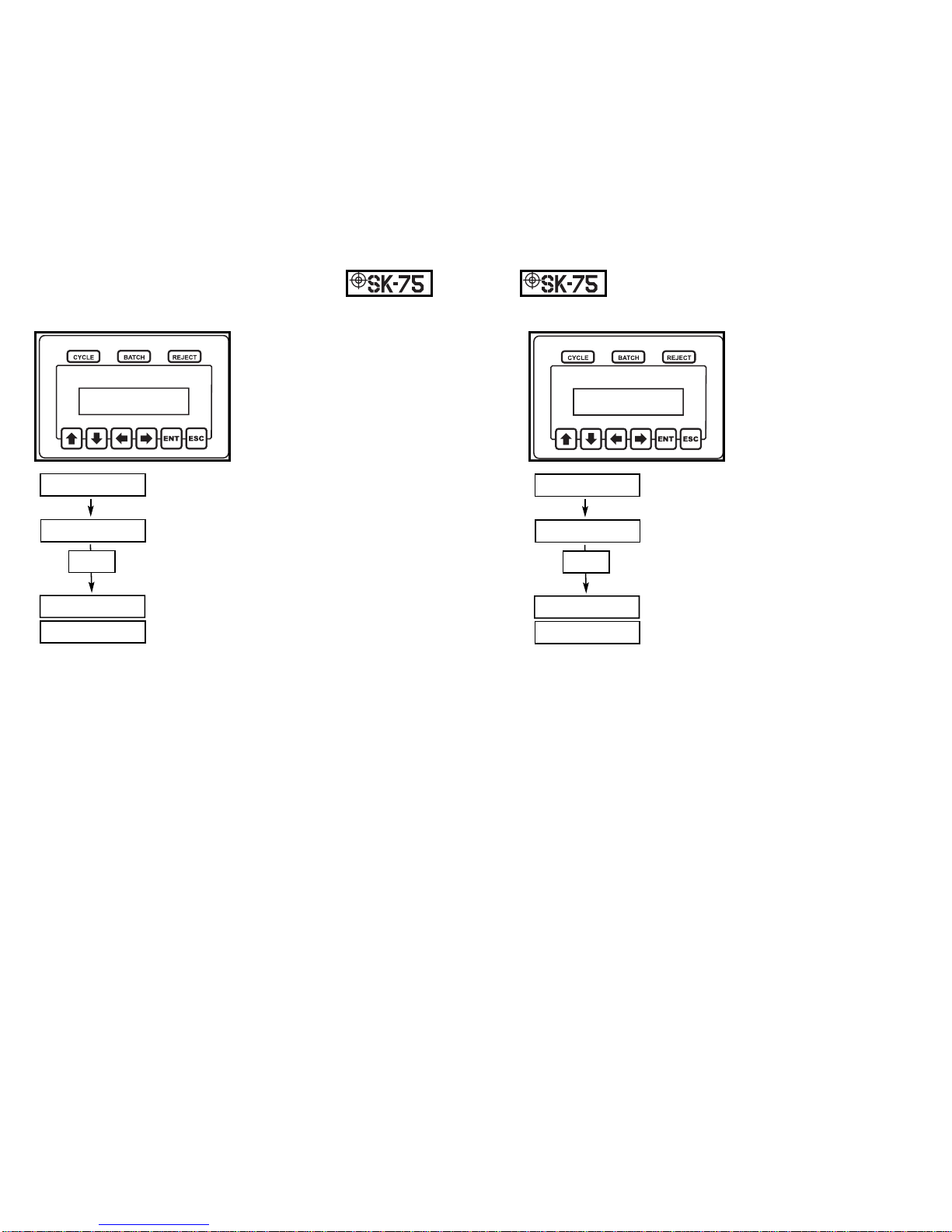

Programming Mode (Bump Timer):

The bump timer defines an

amount of time that a tool can

run and that run will be ignored

if the clutch does not fire (i.e.

torque is not achieved). This

timer may be used to eliminate

nuisance rejects.

In order to edit this value enter the program

mode and press an arrow key until the dis-

play reads PROGRAM MENU, Timer

Bump.

Press the enter button in order to edit the

bump timer’s value.

After the enter button is pressed, the display

will read PROGRAM Tbmp P:Y, Timer =

XX.XXX (where Y is the current parameter

and X is the current timer’s value).

Using the left and right arrow keys select the digit in the timer

value that needs edited. Once the appropriate digit is highlighted,

press the up and down arrows to change the digit’s value.

Proceed in this manner until all of the desired digits are edited.

Once the display shows the appropriate timer value, pressing the

enter button will store the new value to non-volatile memory and

the user will be prompted to Press Any Key. At this point any

button may be pressed and the unit will return to the program

menu.

During the editing process, if the escape button is pressed, the

unit will abort programming the bump timer and return to the

main programming menu.

12

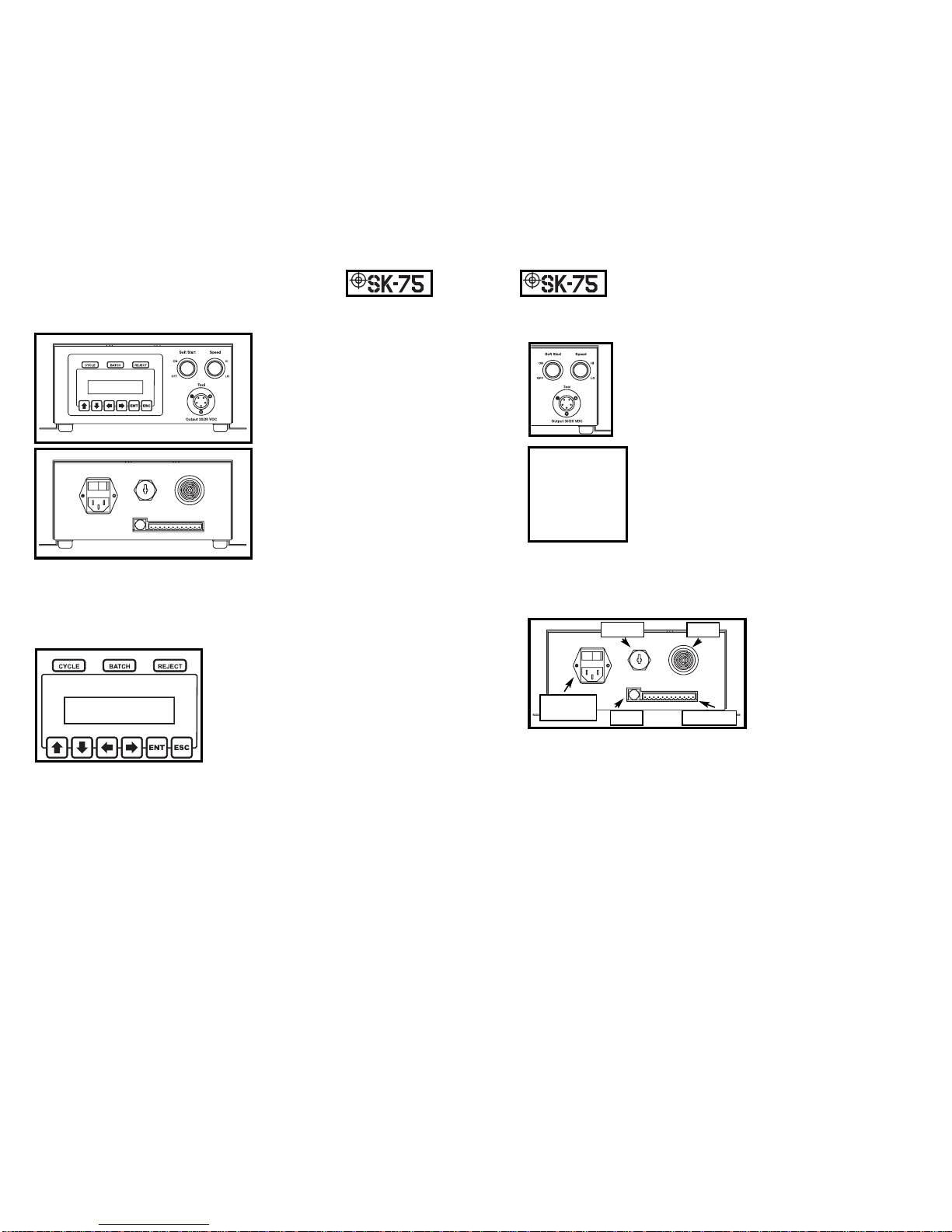

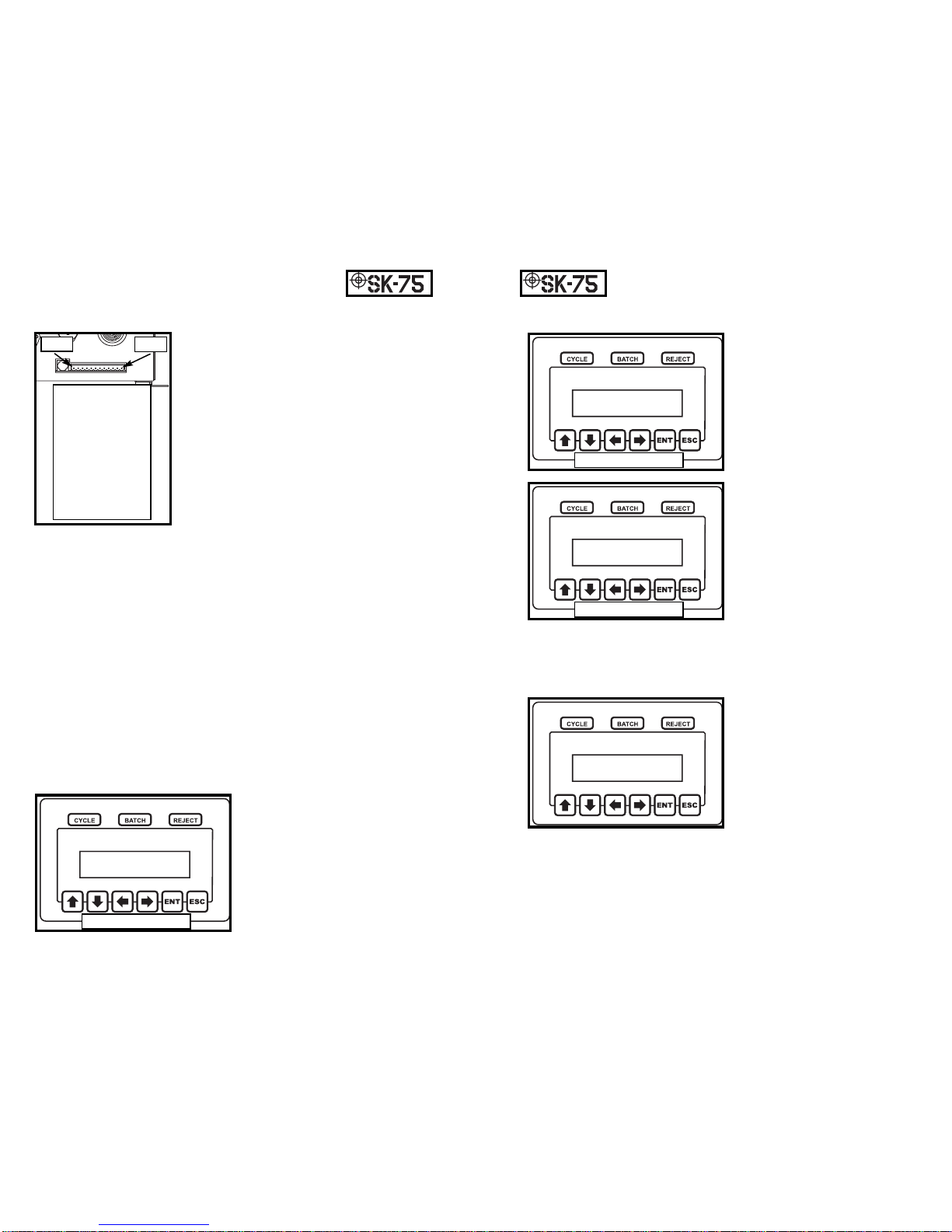

Programming Mode (Maximum Run Timer):

The maximum run timer

defines the maximum amount

of time a tool can run during a

fastening process and still be

considered a good fastening. If

a fastening takes longer than

timer max, a Tmax reject will

be issued.

In order to edit this value enter the program

mode and press an arrow key until the dis-

play reads PROGRAM MENU, Timer Max.

Press the enter button in order to edit the

maximum run timer’s value.

After the enter button is pressed, the display

will read PROGRAM Tmax P:Y, Timer =

XX.XXX (where Y is the current parameter

and X is the current timer’s value).

Using the left and right arrow keys select the digit in the timer

value that needs edited. Once the appropriate digit is highlighted,

press the up and down arrows to change the digit’s value.

Proceed in this manner until all of the desired digits are edited.

Once the display shows the appropriate timer value, pressing the

enter button will store the new value to non-volatile memory and

the user will be prompted to Press Any Key. At this point any

button may be pressed and the unit will return to the program

menu.

During the editing process, if the escape button is pressed, the

unit will abort programming the maximum run time and return to

the main programming menu.

11

PROGRAM MENU

Timer Max

PROGRAM MENU

Timer Max

PROGRAM Tmax P:A

Timer = 03.456

TIMER MAX SAVED

Writing....

Edit Timer

Value

TIMER MAX SAVED

Press Any Key

PROGRAM MENU

Timer Bump

PROGRAM MENU

Timer Bump

PROGRAM Tbmp P:A

Timer = 00.000

TIMER BUMP SAVED

Writing....

Edit Timer

Value

TIMER BUMP SAVED

Press Any Key