SECTION A -INSTALLATION AND OPERATING INSTRUCTIONS

A1 -Unpacking -With the container upright cut the plastic straps around shipping container and lift off top, exposing the Fryer. Check Fryer for any

visible damage due to exceptionally rough handlingduringshipping. ReportdamagetothedeliveringFreightCarrierwithin15daysofdelivery.

A3 -Mounting of Legs or Casters -Carefully tip Fryer up on its back and screw legs or (optional) casters into thethreadedbaseofFryer.When

installing casters make sure the swivel lock casters are mounted towards the front of Fryer. A high strength Restrainer and Quick disconnect Gas

Connector must be installed when casters are used. Avoid putting any strain on rear legs or casters when tipping Fryer back to an upright position.

A4 -Pre-installation Instructions-TheinstallationofyourFryermustbemadebyalicensedplumberandtheinstallationmustconformwithState

and Local Codes or in the absence of Local Codes, with the National Fuel Gas Code ANSI Z223.1 a-Latest Edition.

A5 -AirSupplyandVentilation-AdequateventilationandairsupplymustbeprovidedinorderfortheFryertooperatepropertyandefficiently.The

areainfrontofandabovetheFryermustbecleartoavoidanyobstructionofflowofcombustionandventilationair.Donot. underanycircumstances,

connect the Fryer flue directly to a building exhaust system or place the flue outlet directly into the plenum of the exhaust hood as it will adversely

affect the gas combustion of the Fryer.

The vent system should be of such design as to allow easy access for cleaning and degreasing on a regular basis in order to prevent fires. An

automatic fire extinguishing system should be an integralpart of the vent design. Since the temperature of the flue gases emanatingfromFryerflue

can reach 1200°F, temperature sensing devices of the automatic fire extinguishing system must be sized accordingly and located so as to avoid

premature turn-on. The minimum vertical distance from the top of Fryer flue to vent system filters should be 18 inches or more.

A6 -Clearances -Your Fryer is design certified for use on combustible floors. The minimum clearances for combustible and non-combustible

construction are as follows: 6 inches from SIDE and 6 inches from BACK. Fryer must be installed with 6inchhighlegsorcasters(optional).Atleast

16 inches clearance must be provided between frying surface of fryer and the surface flames from any adjacent cooking equipment.

A7 -GasConnection-BeforeconnectingFryertogasline,checktheratinglabeloninsideofdoorpaneltomakesurethatthegastypecalledforon

label coincides with the type of gas available on sift. A 1/2 inch NPT gas pipe connectionisprovidedattherearofFryer.Anaccessiblemanualshut-

offvalve must be installedinthe gas supply lineahead of the Fryerforfuture service. The sizeofthe supply pipe mustbe sized to accommodateall

the gas fire equipment that may be connected to the gas supply. Check with your local Gas Company as to proper pipe size. Only pipe sealant

resistant to action of L.P. gas should be used on pipe joints. Before attempting to light Fryer check joints for gas tightness using a soap and water

solution. DO NOT USE AN OPEN FLAME.

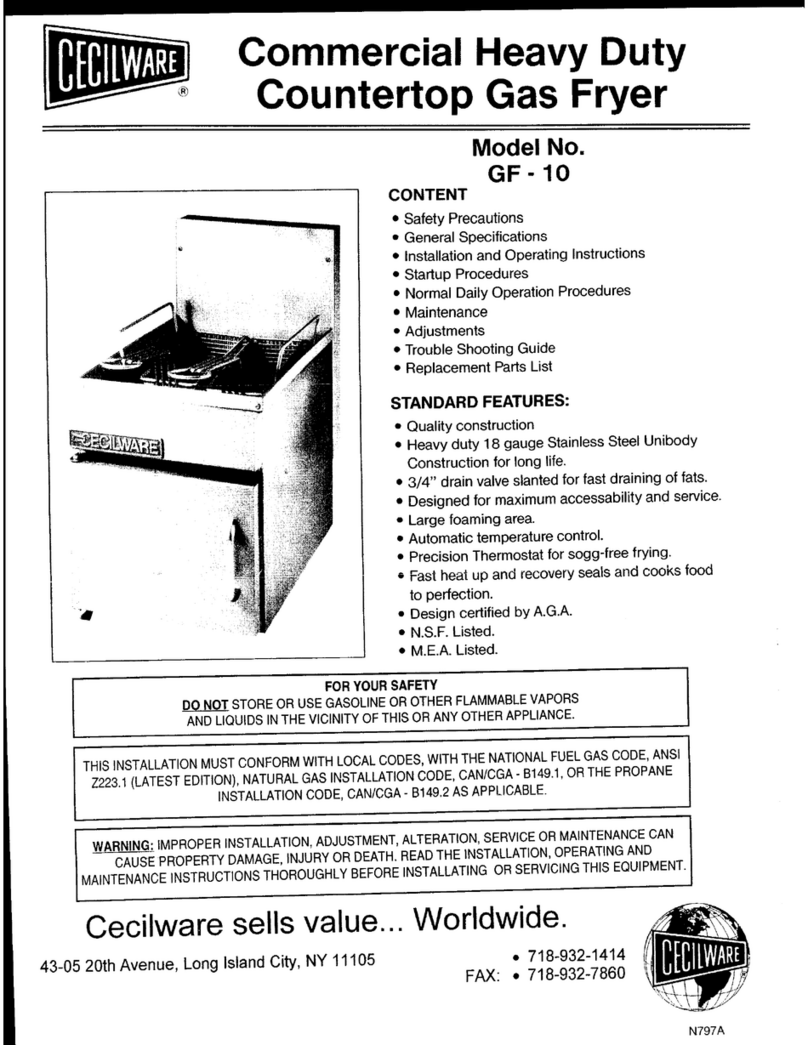

A8 -FlexibleGasConnectorsandRestraints(seeIllustration1)-ForFryersequippedwithcasters,installationshallbemadewithaconnectorthat

complies with the Standard for Connectors for movable Gas Appliances, ANSI Z21.69 or CAN/CGA-6.16 and a Quick-disconnectDevice coupling

with Standard for Quick-disconnect Devices for use with Gas Fuel ANSI Z21.41 or CAN1-6.9. Adequate means shall be provided to limit the

movement of Fryer to prevent undue strain on the Connector orQuick-disconnectDevise.AhighstrengthRestrainerandproperQuick-disconnect

Gas Connector conforming to above ANSI or CAN standards should be ordered from Fryer Manufacturer in conjunction with NSF listed casters. If

disconnection of the Restraint is necessaryforservingofFryer,theRestraintmustbereconnectedafterappliancehasbeenreturnedtoitsoriginally

installed position.

3

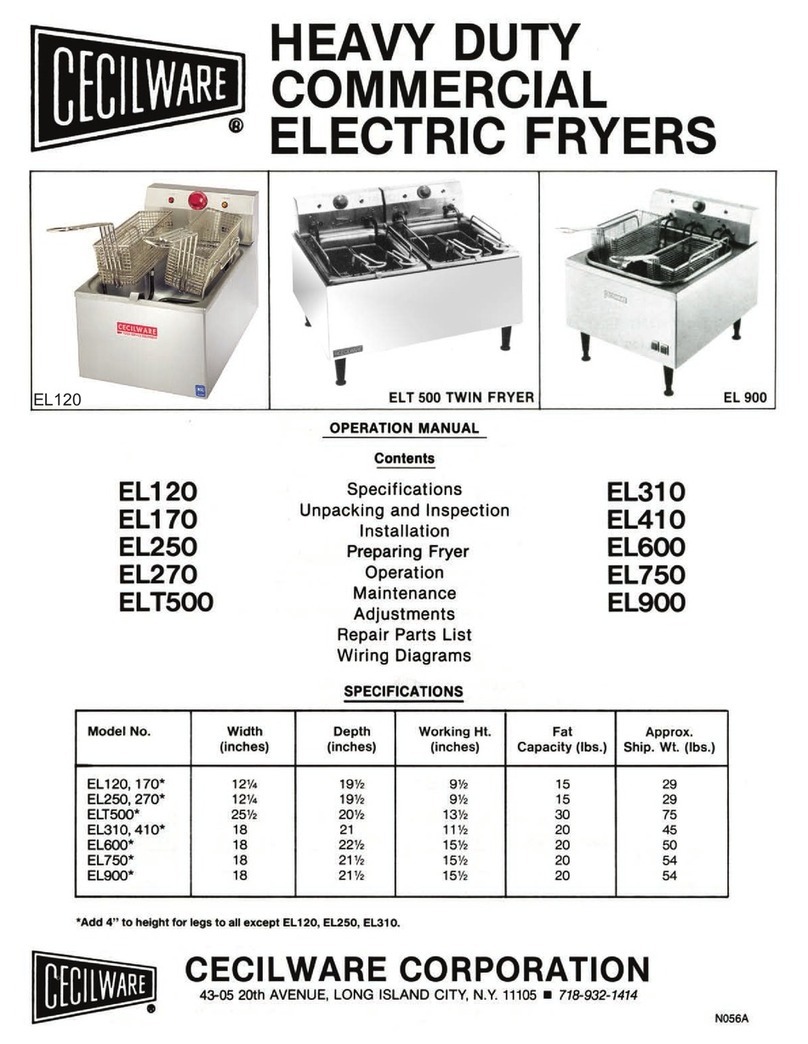

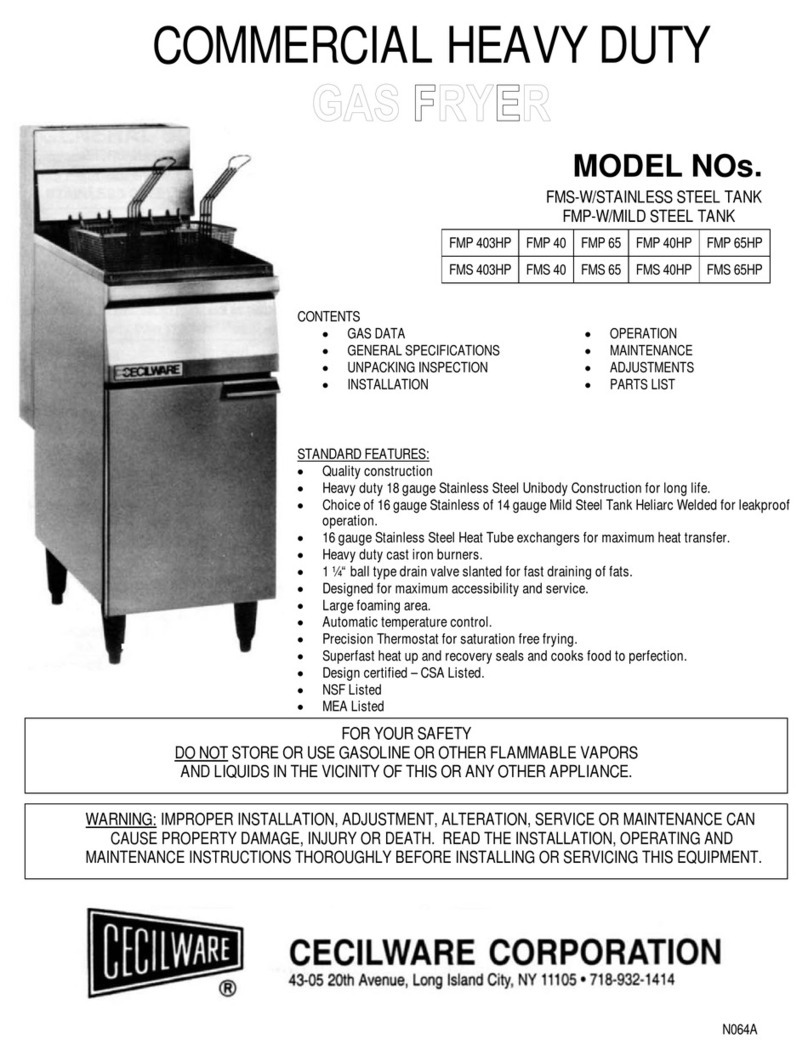

Accessories shipped in the vessel include:

1 -Basket Hanger

2 -Baskets

1 -Drain Pipe Extension

1-Flue Deflector Shield

4 -6 inch Adjustable Legs

Accessories available as optional:

1 -Cover

1 -Twin Basket

4 -Swivel Casters

1-Quick Disconnect Connector 24"

and 36"

1 -Restrainer