1

GB INSTALLATION

RX DC X-RAY UNIT

Contents

1. General safety precautions.......................................................................................................................................3

2. Packaging.................................................................................................................................................................3

2.1. Dimensions and contents................................................................................................................................3

2.2. Handling and storage......................................................................................................................................3

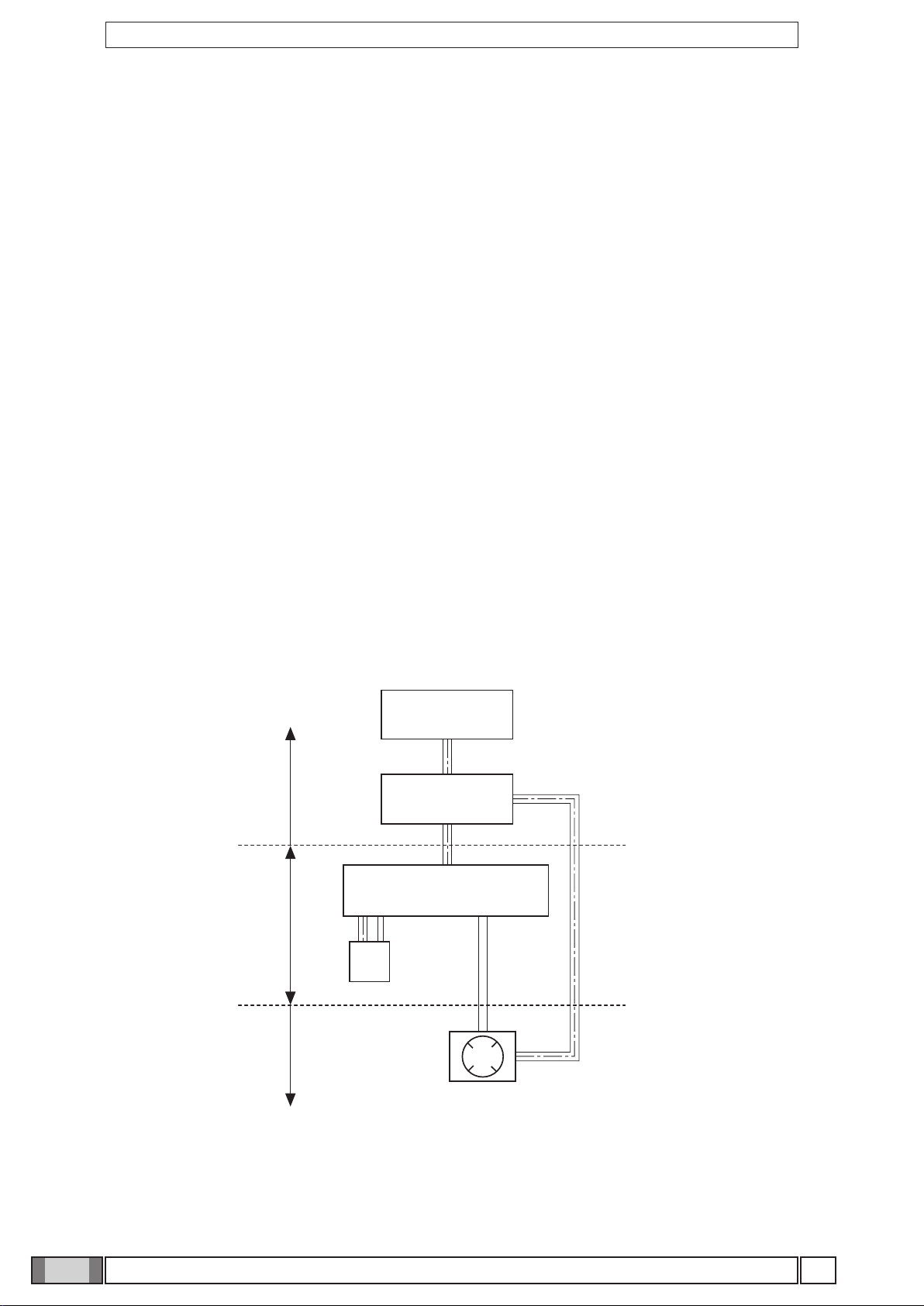

3. Before installation....................................................................................................................................................4

3.1. Mechanical specications required .................................................................................................................4

3.2. Central control unit power supply ...................................................................................................................4

3.3. Wiring connection between central control unit and generator light ..............................................................4

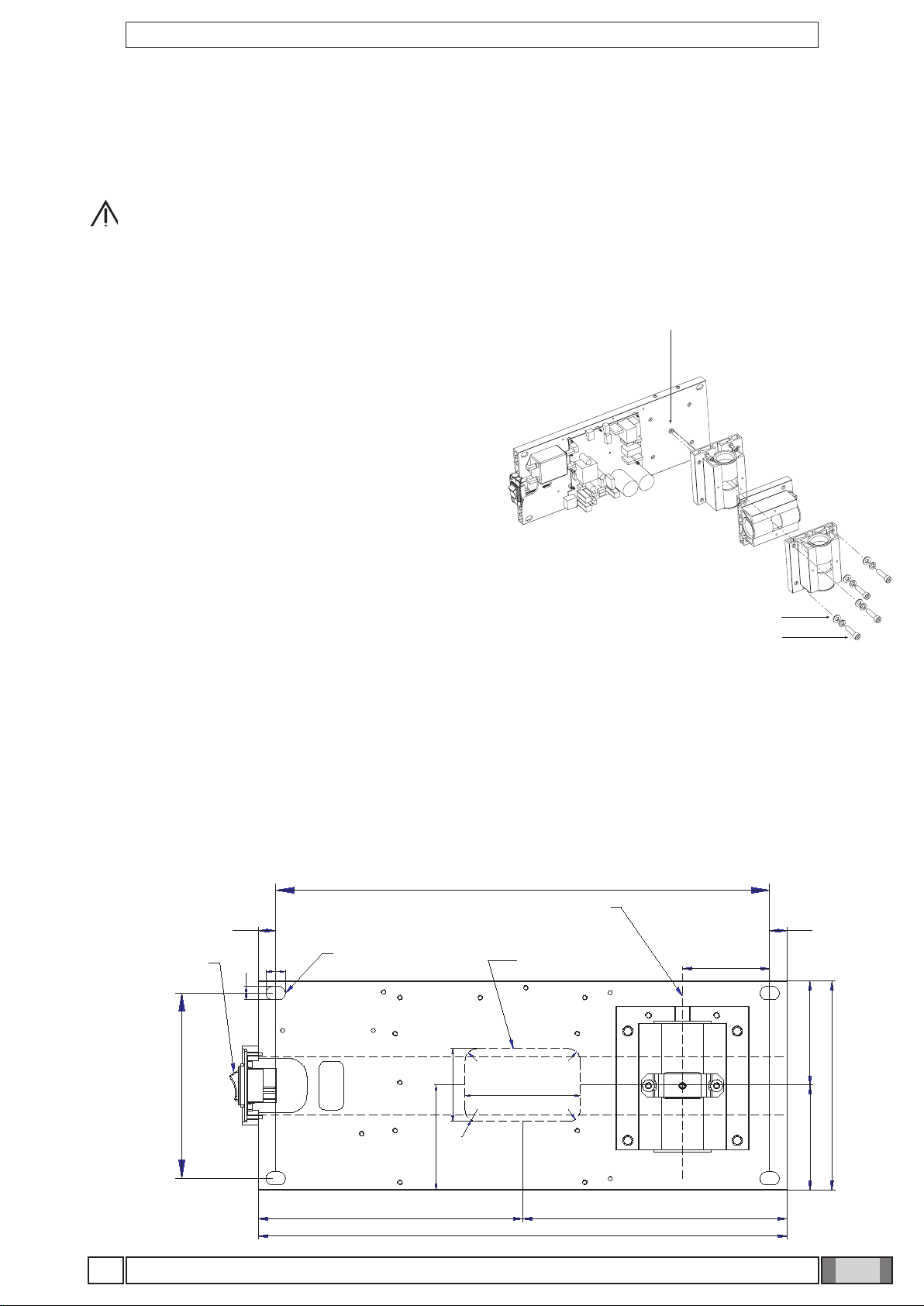

4. Installation ................................................................................................................................................................5

4.1. Positioning the x-ray unit’s structure ...............................................................................................................5

4.2. Wall-mounted plate for supporting the x-ray unit ............................................................................................5

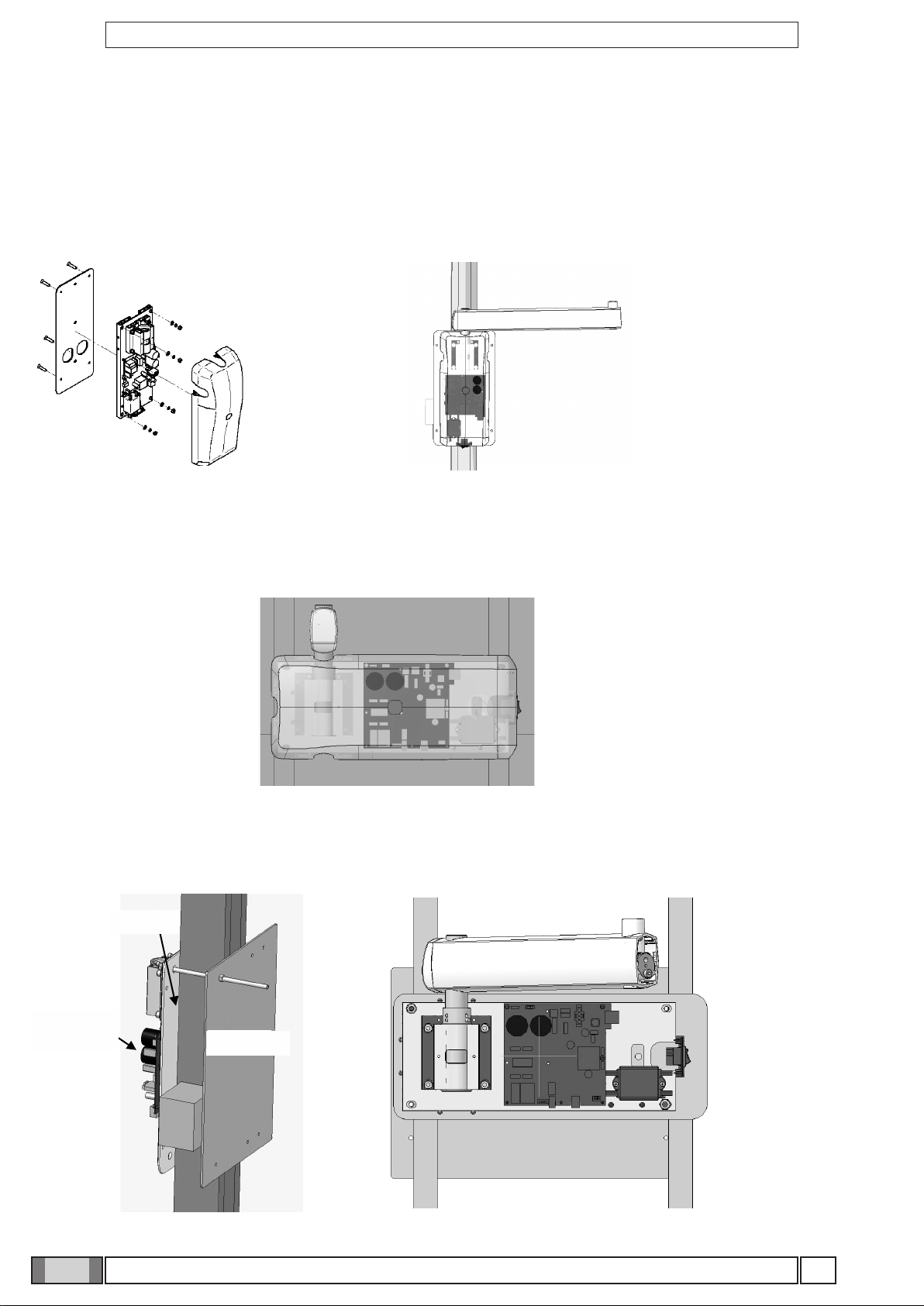

4.2.1. Vertical SINGLE STUD installation with wooden post ......................................................................6

4.2.2. Horizontal SINGLE STUD installation with wooden post...................................................................6

4.2.3. Vertical SINGLE STUD installation with iron post .............................................................................6

4.3. Extension arm .................................................................................................................................................7

4.3.1. PASS THROUGH installation extension arm......................................................................................8

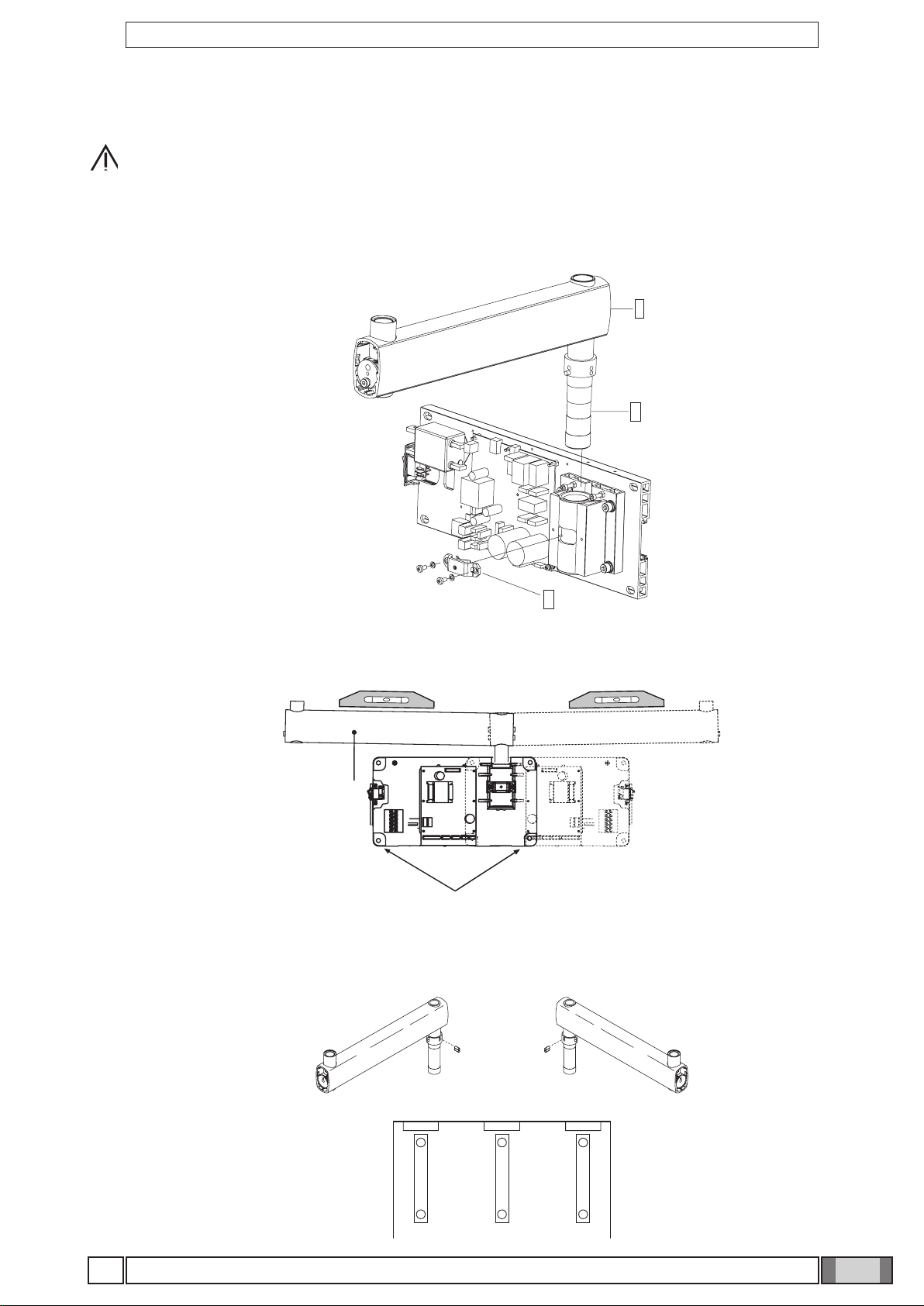

4.4. Installing the double pantograph arm .............................................................................................................9

4.5. Installing the RX DC with "ball end socket joint" generator........................................................................... 11

4.6. Installing the RX DC with standard joint generator ....................................................................................... 11

4.7. Installing the collimator .................................................................................................................................14

4.8. Balancing the double pantograph arm ..........................................................................................................15

4.9. Adjusting the double pantograph arm end-stops ..........................................................................................15

4.10. Wall-mounted plate wiring connections.......................................................................................................16

4.11. Completion of wall-mounting plate and holder for hand-held. ....................................................................17

5. Factory settings ......................................................................................................................................................18

6. Turning on...............................................................................................................................................................18

6.1. Turning The X-ray equipment on and off.......................................................................................................18

6.1.1. Turning on the basic X-ray unit........................................................................................................18

6.1.2. Turning on the handheld...................................................................................................................19

6.1.3. Control panel ....................................................................................................................................19

6.1.4. Automatic handheld shut off .............................................................................................................20

6.1.5. Hand-held stand-by time ..................................................................................................................20

6.1.6. Checking the set parameters ..........................................................................................................21

6.1.7. Factory settings ................................................................................................................................22

7. Batteries and charge level indication .....................................................................................................................22

8. X-ray generator indicator light ................................................................................................................................22

9. Position of the patient............................................................................................................................................23

10. Putting the x-ray unit cone into the required position .........................................................................................23

11. Position of the X-ray plate or sensor....................................................................................................................24

12. Checking the exposure time on the display.........................................................................................................25

12.1. Setting the exposure mode and time .........................................................................................................25

12.2. Setting the mode and exposure time in USER mode .................................................................................26

13 Procedure to be followed when taking the x-ray...................................................................................................27

14. Technician and user setup menu .........................................................................................................................28

14.1. Setting the safety unlock mode ..................................................................................................................29

14.2. Setting the operating mode ........................................................................................................................29

14.3. Setting the type of movable collimator .......................................................................................................29

14.4. Restoring factory settings ..........................................................................................................................29

14.5. Calibrating the X-ray head .........................................................................................................................30

15. Actuator unit (only RX DC with "ball end socket joint").........................................................................................31

16. Control unit card Code 97660515.........................................................................................................................32