Ceiec Electric Technology

4

Table of Contents

Chapter 1 Introduction...................................................................................................................... 5

1.1 Overview ....................................................................................................................................5

1.2 Features......................................................................................................................................5

1.3 Typical Applications ................................................................................................................ 5

1.4 Getting more information.....................................................................................................5

Chapter 2 Installation ........................................................................................................................6

2.1 Appearance ............................................................................................................................... 6

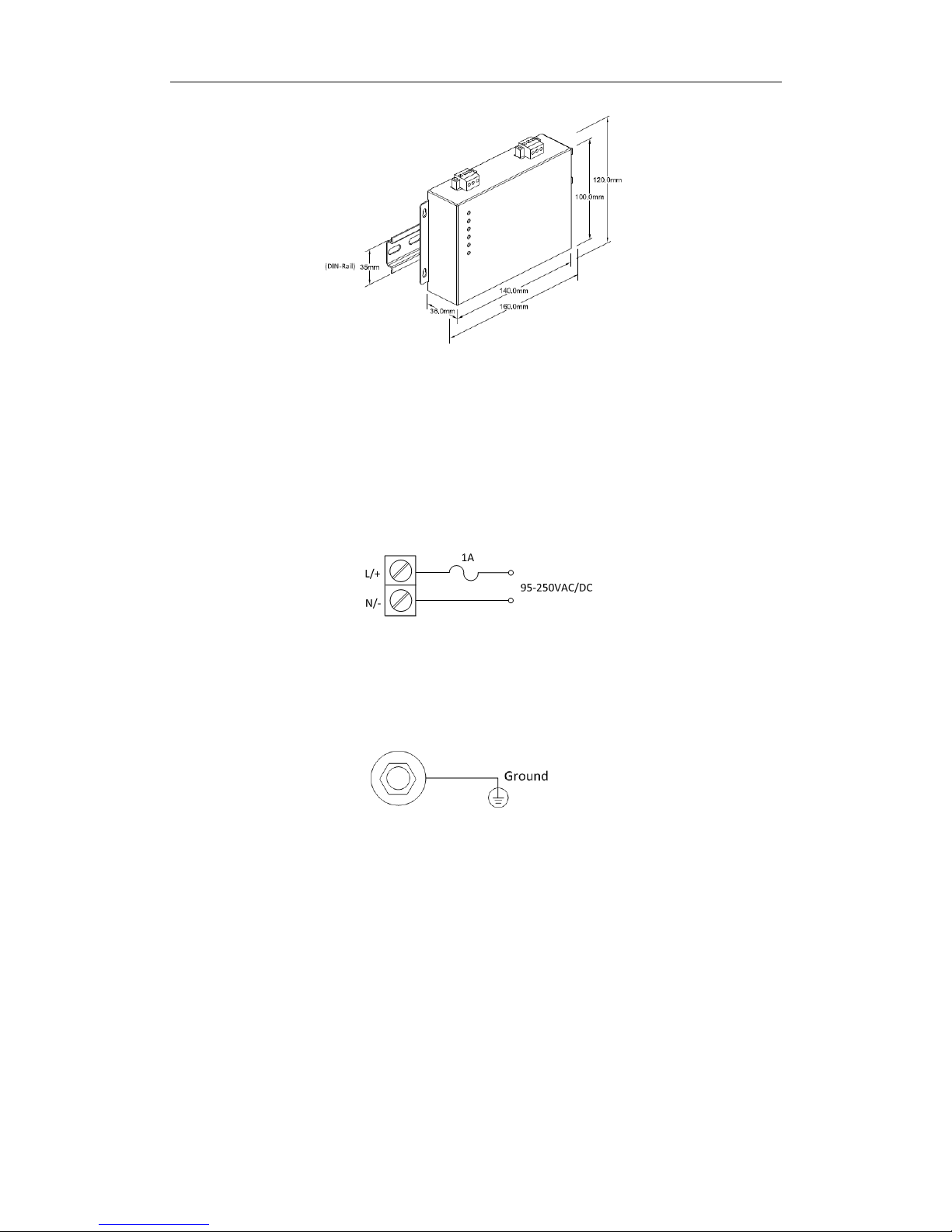

2.2 Unit Dimensions....................................................................................................................... 6

2.3 Mounting ................................................................................................................................... 6

2.4 Power Supply Wiring..............................................................................................................8

2.5 Chassis Ground Wiring........................................................................................................... 8

Chapter 3 Application........................................................................................................................ 9

3.1 LED Indicators ........................................................................................................................... 9

3.2 Typical Application .................................................................................................................. 9

Chapter 4 Communication Settings............................................................................................. 10

4.1 Baud Rate Settings (J1 and J2) ........................................................................................... 10

4.2 Communication Format Settings (J3) ..............................................................................11

4.3 Termination Resistor Settings (J4 to J8) .......................................................................... 11

Appendix A Technical Specifications ........................................................................................... 11

Appendix B Standards of Compliance......................................................................................... 13

Appendix C Ordering Guide ........................................................................................................... 14

Contact us ........................................................................................................................................... 14